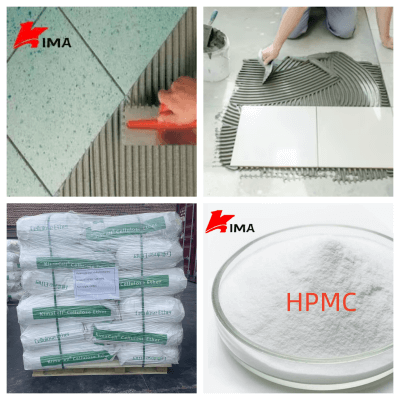

Hydroxypropyl Methylcellulose (HPMC)yog ib qho non-ionic cellulose ether uas siv dav hauv cov ntaub ntawv siv hauv tsev, tshwj xeeb tshaj yog hauv cov nplaum pobzeb. HPMC tau dhau los ua ib qho khoom siv tseem ceeb hauv kev kho kom zoo nkauj niaj hnub los ntawm kev txhim kho kev ua haujlwm ntawm kev tsim kho, kev khaws dej, thiab lub zog sib txuas ntawm cov nplaum pobzeb.

1. Txhim kho kev ua haujlwm ntawm kev tsim kho

1.1. Txhim kho kev ua haujlwm tau zoo

HPMC muaj cov roj nplua nyeem zoo thiab nplaum tau zoo. Ntxiv rau cov nplaum pobzeb tuaj yeem txhim kho qhov ua haujlwm ntawm cov mortar, ua rau nws yooj yim dua rau khawb thiab du, thiab txhim kho kev ua haujlwm zoo thiab kev tsim kho zoo ntawm cov neeg ua haujlwm tsim kho.

1.2. Tiv thaiv kom tsis txhob poob qis

Thaum cov nplaum pobzeb raug siv rau ntawm qhov chaw ntsug, nws yooj yim rau sag vim nws qhov hnyav. HPMC zoo txhim kho cov khoom tiv thaiv kev sag ntawm cov nplaum los ntawm nws cov khoom tuab thiab thixotropic, yog li cov pobzeb tuaj yeem tswj tau qhov chaw ruaj khov tom qab paving thiab tiv thaiv kev nplua.

2. Txhim kho kev khaws dej

2.1. Txo qhov dej poob

HPMC muaj kev ua haujlwm zoo heev rau kev khaws dej. Nws tuaj yeem txo qhov kev ua kom sai ntawm cov dej lossis kev nqus los ntawm cov txheej hauv qab ntawm cov nplaum pobzeb, ua kom ntev lub sijhawm qhib thiab lub sijhawm kho ntawm cov nplaum, thiab muab kev ywj pheej ntau dua rau cov neeg ua haujlwm hauv kev tsim kho.

2.2. Txhawb kom muaj kev sib xyaw ua ke ntawm cov cement hydration

Kev khaws dej zoo pab cov cement kom noo tag nrho thiab tsim cov khoom noo ntau dua, yog li ua kom lub zog sib txuas thiab ruaj khov ntawm cov nplaum pobzeb.

3. Txhim kho lub zog thiab lub zog ntawm kev sib txuas

3.1. Txhim kho cov qauv sib txuas ntawm qhov sib txuas

HPMC tsim cov qauv polymer zoo hauv cov nplaum, uas ua rau kev sib txuas ntawm cov nplaum pobzeb thiab cov vuas thiab txheej hauv paus zoo dua. Txawm hais tias nws yog cov vuas uas nqus tau dej lossis cov vuas uas nqus dej tsawg (xws li cov vuas vitrified thiab cov vuas polished), HPMC tuaj yeem muab lub zog sib txuas ruaj khov.

3.2. Txhim kho qhov tsis kam tawg thiab kev ywj pheej

Cov qauv polymer ntawm HPMC ua rau cov nplais nplaum muaj qee qhov kev ywj pheej, uas tuaj yeem hloov kho rau qhov me me deformation lossis thermal nthuav dav thiab kev cog lus ntawm cov txheej hauv paus, thiab txo cov teeb meem zoo xws li hollowing thiab tawg los ntawm kev ntxhov siab concentration.

4. Txhim kho kev hloov pauv ntawm kev tsim kho

4.1. Hloov kho rau ntau qhov chaw tsim kho

Nyob rau hauv cov huab cua tsis zoo xws li kub siab, qhuav lossis cua hlob, cov nplaum pobzeb ib txwm qhuav sai dhau, ua rau kev sib txuas tsis ua haujlwm. HPMC tuaj yeem ncua qhov dej poob vim nws khaws dej zoo thiab cov yam ntxwv ua zaj duab xis, ua rau cov nplaum pobzeb hloov kho rau kev tsim kho ib txwm muaj hauv ntau qhov chaw.

4.2. Siv tau rau ntau yam khoom siv sib txawv

Txawm nws yog txheej cement mortar leveling, pob zeb ua vaj tse, cov vuas qub lossis cov gypsum substrate, cov nplaum pobzeb nrog HPMC ntxiv tuaj yeem muab kev ua tau zoo ntawm kev sib txuas, nthuav dav nws cov ntawv thov.

5. Kev tiv thaiv ib puag ncig thiab kev nyab xeeb

HPMC yog cov khoom siv ntsuab thiab zoo rau ib puag ncig, tsis muaj tshuaj lom, tsis muaj ntxhiab, tsis kub hnyiab, thiab yuav tsis ua rau ib puag ncig lossis tib neeg noj qab haus huv puas tsuaj. Nws tsis tso cov tshuaj lom thaum lub sijhawm tsim kho, uas yog raws li lub tswv yim kev tsim kho ntawm cov tsev ntsuab niaj hnub.

6. Kev lag luam thiab kev ua haujlwm ntev

Txawm hais tias tus nqi ntawm HPMC siab dua me ntsis dua li cov khoom siv ntxiv ib txwm muaj, nws txhim kho kev ua tau zoo ntawm cov nplaum pobzeb, txo qhov nrawm ntawm kev ua haujlwm dua thiab cov khoom pov tseg, thiab muaj txiaj ntsig zoo rau kev lag luam hauv lub sijhawm ntev. Cov nplaum pobzeb zoo txhais tau tias tsawg dua kev saib xyuas, lub neej ua haujlwm ntev dua thiab cov txiaj ntsig zoo dua ntawm kev tsim kho.

7. Kev sib koom tes nrog lwm cov khoom siv ntxiv

HPMC siv tau ua ke nrog ntau yam khoom ntxiv, xws liCov Hmoov Polymer Uas Rov Qab Tau(RDP), hmoov txhuv nplej siab ether, tus neeg sawv cev khaws dej, thiab lwm yam, kom ua kom zoo dua qhov kev ua tau zoo ntawm cov nplaum pobzeb. Piv txwv li, thaum siv nrog RDP, nws tuaj yeem txhim kho qhov yooj ywm thiab lub zog sib txuas; thaum siv nrog hmoov txhuv nplej siab ether, nws tuaj yeem txhim kho qhov kev khaws dej thiab kev ua kom du.

HPMC ua lub luag haujlwm tseem ceeb hauv cov nplaum pobzeb hauv ntau yamNws cov txiaj ntsig tseem ceeb suav nrog kev txhim kho kev ua haujlwm ntawm kev tsim kho, txhim kho kev khaws dej, txhim kho kev nplaum, txhim kho kev muaj peev xwm tiv thaiv kev sagging, thiab hloov kho rau ntau yam substrates thiab ib puag ncig. Ua ib qho khoom siv tseem ceeb rau kev tsim kho pob zeb niaj hnub, HPMC tsis yog tsuas yog ua tau raws li ntau yam kev xav tau ntawm kev tsim kho tam sim no, tab sis kuj txhawb nqa kev nce qib hauv kev siv tshuab thiab kev txhim kho ntsuab hauv kev lag luam nplaum pob zeb.

Lub sijhawm tshaj tawm: Lub Rau Hli-24-2025