Hauv kev tsim khoom lag luam thiab kev tsim tsheb, kev siv tshuab sealing yog qhov tseem ceeb rau kev ua haujlwm ntawm cov khoom siv. Tsis ntev los no, lub foob pob hluav taws xob ob lub qhov (dual-connector seal) uas muaj kev tsim tshiab thiab kev ua tau zoo heev tau nkag mus rau hauv kev ua lag luam, muab kev daws teeb meem sealing tshiab rau kev lag luam thiab ua rau muaj kev saib xyuas dav dav. Tib lub sijhawm, daim duab qhia txog lub cav thiab nws cov khoom tau muab faib dav dav hauv online, ua rau tib neeg nkag siab ntxiv txog cov qauv cav thiab kev siv cov khoom sealing.

1. Cov Khoom Muag thiab Cov Khoom Siv

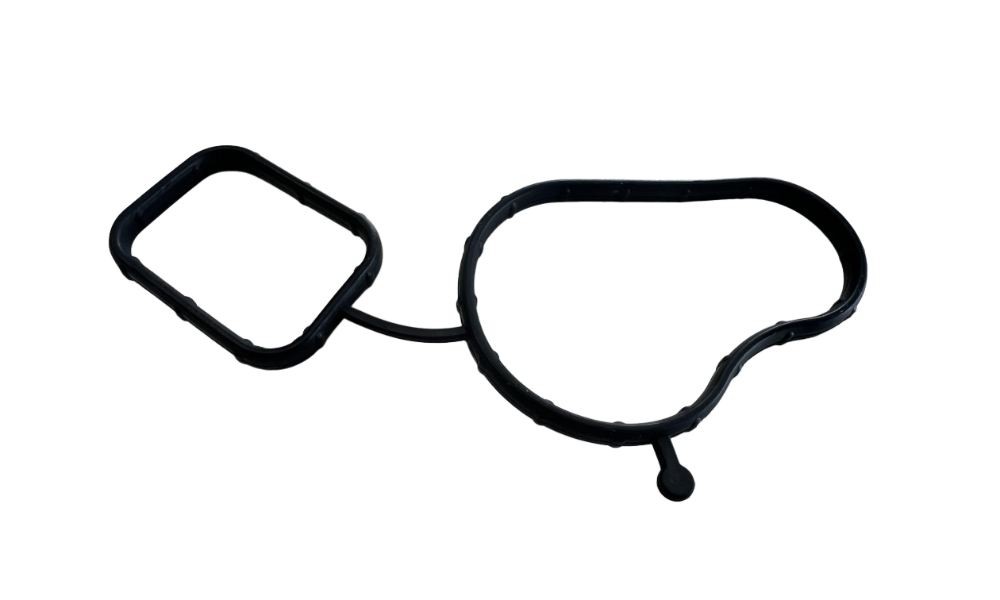

Lub foob sib txuas ob lub muaj ob lub nplhaib roj hmab txuas: ib sab yog lub nplhaib plaub fab, thaum sab tod yog lub nplhaib elliptical loj nrog lub cim me me ntawm qhov kawg. Tus qauv tsim no tsis yog tsuas yog ua tiav kev tsim kho tshiab xwb tab sis kuj xav txog tag nrho cov kev xav tau ua haujlwm hauv kev teeb tsa thiab kev siv tiag tiag. Nws yog ua los ntawm cov roj hmab zoo thiab ua tiav los ntawm kev siv tshuab vulcanization siab heev. Cov khoom siv roj hmab nws tus kheej muaj kev ywj pheej zoo heev, kev tiv thaiv kev hnav, thiab kev tiv thaiv corrosion. Cov txheej txheem vulcanization ntxiv txhim kho nws cov qauv molecular, xyuas kom meej tias nws tswj tau cov khoom ruaj khov hauv qhov kub ntawm -40 ° C txog 150 ° C thiab hauv qhov kub siab, cov chaw muaj tshuaj lom neeg, tiv thaiv kev laus, kev hloov pauv, thiab lwm yam teeb meem, xyuas kom meej tias kev ua haujlwm sealing ntev.

2. Cov Haujlwm Tseem Ceeb thiab Cov Ntawv Thov

(a) Kev Ua Haujlwm Zoo Kawg Nkaus ntawm Kev Sib Nqus

Hauv cov khoom siv kho tshuab thiab tsheb, cov kua xau yog qhov tseem ceeb uas cuam tshuam rau kev ua haujlwm ib txwm. Ua tsaug rau nws cov duab tshwj xeeb thiab cov khoom siv roj hmab zoo, lub foob ob lub qhov txuas tuaj yeem ua kom tiav cov qhov me me ntawm cov khoom, tsim kom muaj kev sib khi zoo. Piv txwv li, hauv cov cav tsheb, xav tau lub gasket taub hau ntawm lub taub hau lub tog raj kheej thiab lub tog raj kheej thaiv kom tiv thaiv cov dej txias thiab roj cav xau. Lub nplhaib plaub fab ntawm lub foob ob lub qhov txuas tuaj yeem hloov kho kom haum rau cov interfaces zoo sib xws, tiv thaiv cov roj thiab cov dej txias xau thiab sib xyaw, ua kom lub cav ua haujlwm ruaj khov hauv qhov kub thiab txias, siab siab, thiab kev co, tswj cov roj nplua nyeem zoo thiab cov teebmeem txias, thiab ua kom lub cav siv tau ntev. Hauv cov tshuab hydraulic ntawm cov khoom siv kho tshuab, lub nplhaib elliptical haum rau cov khoom sib txuas ntawm cov tog raj kheej hydraulic thiab cov twj tso kua mis, tswj kev sib khi hauv qab cov roj siab vim nws muaj peev xwm hloov pauv tau zoo heev, ua kom cov tshuab hydraulic ua haujlwm tau zoo thiab txhim kho kev ua haujlwm kho tshuab thiab kev ua haujlwm raug.

(b) Kev Txuas thiab Kev Kho Kom Ruaj Kho

Lub qauv ob-ntiv nplhaib ntawm lub foob ob-txuas muab nws ob qho tib si kev sib khi thiab kev sib txuas. Hauv kev sib dhos ntawm cov khoom siv hauv tsheb, xws li kev sib txuas ntawm lub qhov nqus manifold thiab lub cav thaiv, lub foob tau teeb tsa ntawm qhov sib txuas, tsis yog tsuas yog muab kev sib khi kom tiv thaiv kev xau tab sis kuj txhim kho qhov nruj ntawm kev sib txuas los ntawm kev hloov pauv elastic thiab cov yam ntxwv ntawm cov qauv, txo qhov kev pheej hmoo ntawm kev ua tsis tiav los ntawm kev xoob. Hauv cov kab ke hauv kev lag luam, nws ua kom yooj yim rau cov txheej txheem sib txuas yeeb nkab, hloov cov txheej txheem sib txuas bolt thiab txiv ntoo nyuaj, ua rau kev sib khi yeeb nkab sai thiab kho, txo qhov kev pheej hmoo ntawm kev xau, txo cov nqi txij nkawm thiab qhov nyuaj, thiab txhim kho kev thauj khoom zoo thiab kev nyab xeeb.

3. Cov txiaj ntsig zoo ntawm kev ua tau zoo

(a) Kev Hloov Kho Tau Dav Dav

Cov khoom siv hauv kev lag luam thiab cov kws kho tsheb feem ntau ntsib qhov kub thiab txias heev. Cov khoom siv roj hmab ntawm lub foob ob lub qhov txuas tau tsim tshwj xeeb los tswj kev ua haujlwm ruaj khov thiab kev ua haujlwm ntawm kev sib khi hauv qhov kub ntawm -40 ° C txog 150 ° C. Thaum lub caij ntuj no txias, nws tuaj yeem rov qab tau nws qhov elasticity sai sai kom ntseeg tau tias lubrication ntawm cov cav tsheb, thaum nyob rau hauv qhov kub thiab txias, nws tsis mos lossis deform, tiv thaiv cov khoom sab hauv thiab cov kua dej tas li.

(b) Kev Tiv Thaiv Kev Hnav Thiab Kev Laus

Kev txav mus los ntawm cov khoom siv thiab kev siv tsheb mus sij hawm ntev ua rau cov foob raug kev sib txhuam tas mus li thiab kev ntxhov siab ntawm lub tshuab. Lub foob ob lub qhov txuas siv cov khoom siv roj hmab zoo nrog kev kho tshwj xeeb rau saum npoo kom txo qhov kev sib txhuam, ua rau qeeb hnav. Tsis tas li ntawd, cov tshuaj ntxiv tiv thaiv kev laus ntxiv rau lub foob tiv taus cov teebmeem ntawm UV rays, ozone, thiab lwm yam ib puag ncig. Txawm tias tom qab kev txav mus los ntawm lub tshuab mus sij hawm ntev, nws tseem khaws tau qhov elasticity zoo thiab kev ua haujlwm ntawm kev kaw, txo qhov zaus ntawm kev saib xyuas thiab hloov cov khoom siv, txo cov nqi ua haujlwm, thiab txhim kho kev ua haujlwm ntau lawm.

(c) Kev Tiv Thaiv Tshuaj Lom Zem Dav Dav

Hauv kev tsim khoom lag luam thiab kev ua haujlwm hauv tsheb, cov foob pob hluav taws raug rau ntau yam tshuaj lom neeg. Cov khoom siv roj hmab ntawm lub foob pob hluav taws ob lub qhov txuas tau tsim los kom muaj kev tiv taus zoo rau cov kua dej hauv tsheb, cov roj hydraulic hauv kev lag luam, cov roj nplua nyeem, thiab lwm yam tshuaj. Nws tsis hloov pauv lub cev lossis tshuaj lom neeg txawm tias tom qab raug rau lub sijhawm ntev, tiv thaiv cov kua dej xau thiab xeb ntawm cov khoom siv, ua kom ntseeg tau tias cov khoom siv ua haujlwm ruaj khov hauv cov chaw muaj tshuaj lom neeg nyuaj.

4. Txoj Haujlwm thiab Kev Ua Haujlwm ntawm Cov Ntiv Tes Sib Txuas Ob Chav Hauv Cav

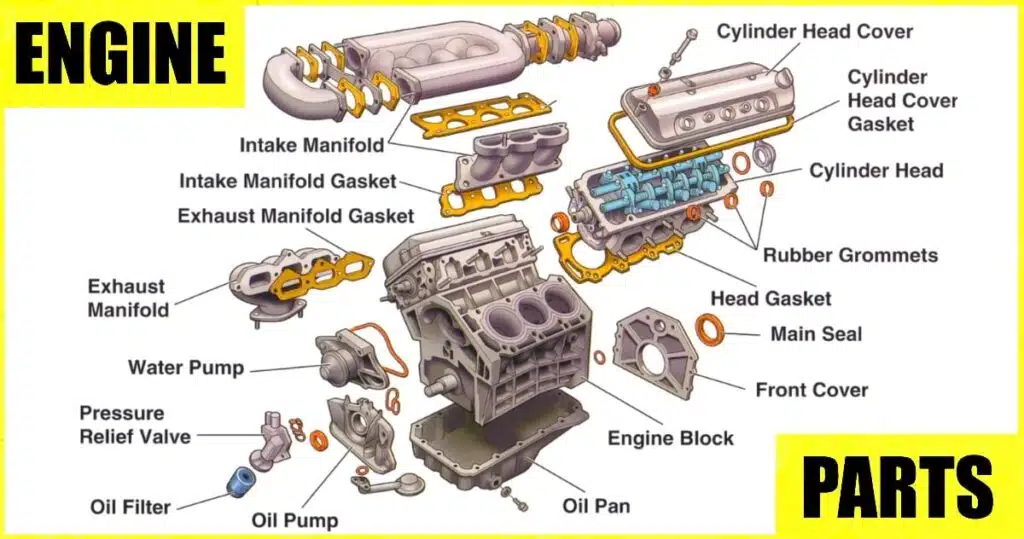

Los ntawm daim duab, nws tuaj yeem pom tias lub foob ob-txuas yog feem ntau ntsia nruab nrab ntawm lub qhov nqus manifold thiab lub cav thaiv, nrog rau ntawm lub tog raj kheej thaiv thiab lub taub hau lub tog raj kheej. Hauv cov cheeb tsam tseem ceeb no, lub foob ob-txuas ua lub luag haujlwm tseem ceeb hauv kev sib khi. Lub nplhaib plaub fab sib haum xeeb ntawm qhov sib txuas ntawm lub taub hau lub tog raj kheej thiab lub tog raj kheej thaiv, tiv thaiv kev xau ntawm cov roj cav thiab cov dej txias thiab xyuas kom meej tias cov kua hauv lub cav tswj tau cov roj nplua nyeem thiab cov dej txias hauv qab qhov kub siab, siab siab, thiab kev co. Lub nplhaib elliptical yog ntsia nruab nrab ntawm lub qhov nqus manifold thiab lub tog raj kheej thaiv, xyuas kom meej tias kev sib khi ntawm cov txheej txheem nkag mus kom cov pa lossis cov khoom sib xyaw ua ke tuaj yeem nkag mus rau txhua lub tog raj kheej sib npaug thiab raug, yog li ua kom lub cav ua haujlwm zoo thiab lub zog tso zis. Cov lus qhia yooj yim no tsis yog tsuas yog tso cai rau ntau tus neeg kom nkag siab tob dua txog lub foob ob-txuas tab sis kuj muab cov ntaub ntawv siv tau zoo rau cov kws tshaj lij hauv kev lag luam, txhawb kev sib pauv thiab kev tsim kho tshiab ntawm cov thev naus laus zis sib khi.

Lub sijhawm tshaj tawm: Tsib Hlis-21-2025