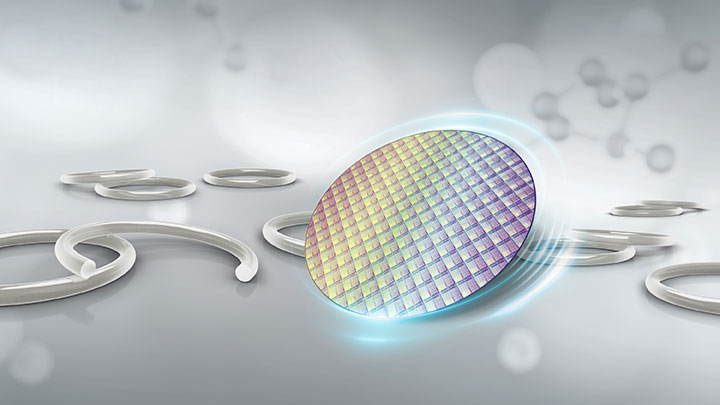

Hauv kev tsim khoom siv thev naus laus zis siab heev, txhua kauj ruam xav tau kev ua tib zoo thiab kev huv si. Cov roj hmab tshwj xeeb, ua cov khoom tseem ceeb uas ua kom cov khoom siv tsim khoom ua haujlwm ruaj khov thiab tswj hwm qhov chaw tsim khoom huv si, muaj kev cuam tshuam ncaj qha rau cov txiaj ntsig thiab kev ua tau zoo ntawm cov khoom siv semiconductor. Niaj hnub no, peb yuav kawm txog seb cov roj hmab tshwj xeeb xws li fluororubber thiab perfluoroelastomer ua lub luag haujlwm tseem ceeb hauv kev tsim khoom semiconductor li cas.

I. Cov Kev Cai Uas Yuav Tsum Tau Ua Rau Cov Chaw Tsim Khoom Semiconductor

Kev tsim khoom semiconductor feem ntau yog ua nyob rau hauv chav huv, qhov twg qhov yuav tsum tau ua kom huv si ntawm ib puag ncig yog siab heev. Txawm tias cov khoom me me ntawm cov pa phem tuaj yeem ua rau cov hluav taws xob luv luv lossis lwm yam kev ua tsis zoo. Ntxiv mus, cov txheej txheem tsim khoom cuam tshuam nrog kev siv ntau yam tshuaj lom neeg corrosive heev, xws li photoresists, etching solutions, thiab cov kua ntxuav. Ntxiv mus, qee cov kauj ruam ntawm cov txheej txheem muaj kev hloov pauv kub thiab siab. Piv txwv li, etching thiab ion implantation txheej txheem tsim kom muaj qhov kub thiab txias siab thiab siab hauv cov khoom siv. Ntxiv mus, precipitates los ntawm cov foob tuaj yeem muaj kev cuam tshuam loj heev rau kev tsim khoom semiconductor. Txawm tias cov precipitates me me tuaj yeem ua rau cov ntaub ntawv semiconductor lossis cov txheej txheem ua qias tuaj, cuam tshuam qhov tseeb ntawm cov txheej txheem tsim khoom.

II. Lub Luag Haujlwm Tseem Ceeb ntawm Cov Roj Hmab Tshwj Xeeb

1. Tiv Thaiv Kev Ua Phem Rau Cov Khoom Me Me: Cov roj hmab tshwj xeeb zoo tiv thaiv cov hmoov av, cov khoom tsis huv, thiab lwm yam khoom me me los ntawm ib puag ncig sab nraud kom tsis txhob nkag mus rau hauv cov khoom siv, ua kom ib puag ncig huv si. Piv txwv li, siv cov roj hmab perfluoroelastomer ua piv txwv, lawv qhov chaw du thiab tiv taus kev nqus cov khoom me me. Lawv qhov kev ywj pheej zoo heev ua rau lawv haum rau cov khoom siv, tsim kom muaj kev sib khi zoo thiab ua kom ntseeg tau tias cov txheej txheem tsim khoom semiconductor tsis muaj kev ua qias tuaj ntawm cov khoom me me.

2. Tiv Thaiv Kev Xeb Tshuaj: Cov ntsaws ruaj ruaj xws li fluorocarbon thiab perfluoroelastomer muaj kev tiv thaiv zoo heev rau cov tshuaj reagents feem ntau siv hauv kev tsim khoom semiconductor. Cov ntsaws ruaj ruaj Fluorocarbon tiv taus cov kua qaub thiab alkaline thiab cov kuab tshuaj organic, thaum cov ntsaws ruaj ruaj perfluoroelastomer ruaj khov tshwj xeeb hauv cov chaw muaj tshuaj oxidizing thiab corrosive heev. Piv txwv li, hauv cov txheej txheem etching ntub, cov ntsaws ruaj ruaj perfluoroelastomer tuaj yeem tiv taus kev sib cuag ntev nrog cov kua qaub etching ntau yam tsis muaj xeb, ua kom ntseeg tau tias kev sib khi thiab kev ruaj khov ntawm cov khoom siv.

3. Kev Hloov Kho Rau Qhov Kub Thiab Kev Hloov Pauv Siab: Cov khoom siv tsim khoom semiconductor ntsib kev hloov pauv kub thiab siab ntau zaus thaum lub sijhawm ua haujlwm. Cov roj hmab tshwj xeeb xav tau kev tiv taus kub siab thiab qis zoo heev, nrog rau kev ywj pheej zoo heev thiab kev tiv taus siab. Cov roj hmab fluororubber tswj tau qhov ywj pheej zoo heev thiab cov khoom kaw hauv qee qhov kub thiab txias, hloov kho rau kev hloov pauv kub thaum lub sijhawm ua ntau yam. Cov roj hmab perfluoroelastomer, ntawm qhov tod tes, tsis yog tsuas yog tiv taus qhov kub siab xwb tab sis kuj tiv taus kev tawv lossis brittle ntawm qhov kub qis, tswj kev ua haujlwm sealing txhim khu kev qha thiab xyuas kom meej tias cov khoom siv ua haujlwm ib txwm nyob rau hauv ntau yam kev ua haujlwm nyuaj.

4. Tswj Kev Pheej Hmoo ntawm Kev Nag: Kev tswj kev nag los ntawm cov foob yog qhov tseem ceeb hauv kev tsim khoom semiconductor. Cov foob roj hmab tshwj xeeb xws li fluoroelastomer thiab perfluoroelastomer siv cov qauv zoo tshaj plaws thiab cov txheej txheem tsim khoom kom txo qis kev siv ntau yam khoom ntxiv, yog li txo qhov yuav muaj kev nag ntawm cov khoom tsis huv xws li cov organic me me thiab cov hlau ions thaum lub sijhawm tsim khoom. Cov yam ntxwv nag tsawg no ua kom ntseeg tau tias cov foob tsis dhau los ua qhov chaw ua qias tuaj, tswj hwm qhov chaw huv si uas xav tau rau kev tsim khoom semiconductor.

III. Cov Kev Cai Ua Haujlwm thiab Cov Qauv Xaiv rau Cov Roj Hmab Tshwj Xeeb

1. Cov Khoom Uas Muaj Feem Xyuam Txog Kev Huv: Qhov ntxhib ntawm qhov chaw, qhov hloov pauv, thiab qhov tso tawm ntawm cov khoom me me yog cov cim qhia tseem ceeb ntawm cov foob. Cov foob uas muaj qhov ntxhib ntawm qhov chaw tsawg tsawg yuav tsis yooj yim rau cov khoom me me sib sau ua ke, thaum qhov hloov pauv tsawg yuav txo qhov kev pheej hmoo ntawm cov pa roj organic los ntawm cov foob hauv qhov chaw kub siab. Thaum xaiv cov foob, muab qhov tseem ceeb rau cov khoom uas muaj kev kho tshwj xeeb ntawm qhov chaw uas muaj qhov hloov pauv tsawg thiab qhov tso tawm ntawm cov khoom me me. Piv txwv li, cov foob perfluoroelastomer uas kho nrog plasma muab qhov chaw du thiab txo qhov hloov pauv tau zoo. Tsis tas li ntawd, xyuam xim rau cov khoom tso tawm ntawm cov foob thiab xaiv cov khoom uas tau dhau los ntawm kev sim tso tawm kom ntseeg tau tias lawv tsis muaj cov pa phem hauv cov chaw tsim khoom semiconductor.

2. Kev sib raug zoo ntawm cov tshuaj lom neeg: Xaiv cov khoom siv roj hmab uas tsim nyog raws li cov tshuaj reagents tshwj xeeb uas ntsib thaum lub sijhawm tsim khoom semiconductor. Ntau hom fluoroelastomer thiab perfluoroelastomer muaj kev tiv thaiv sib txawv rau cov tshuaj sib txawv. Rau cov txheej txheem uas muaj cov kua qaub oxidizing muaj zog, yuav tsum xaiv cov foob perfluoroelastomer uas muaj oxidizing heev. Rau cov txheej txheem uas muaj cov kuab tshuaj organic dav dav, cov foob fluoroelastomer yuav yog qhov kev xaiv pheej yig dua.

3. Cov khoom siv lub cev: Cov no suav nrog qhov nyuaj, elastic modulus, thiab compression set. Cov foob nrog qhov nyuaj nruab nrab ua kom muaj kev sib khi zoo thaum tseem ua rau kev teeb tsa thiab tshem tawm yooj yim. Elastic modulus thiab compression set qhia txog kev ruaj khov ntawm lub foob hauv qab kev ntxhov siab ntev. Hauv qhov kub thiab txias thiab siab, cov foob nrog qhov compression tsawg kawg nkaus yuav tsum tau xaiv kom ntseeg tau tias kev ua haujlwm sealing ruaj khov mus sij hawm ntev.

IV. Kev Tshuaj Xyuas Cov Ntaub Ntawv Siv Tau

Ib lub tuam txhab tsim khoom semiconductor uas paub zoo tau ntsib teeb meem xeb thiab laus ntawm cov roj hmab foob hauv cov khoom siv etching ntawm nws cov kab tsim khoom chip. Qhov no ua rau muaj kev xau sab hauv, cuam tshuam rau kev ua haujlwm zoo thiab txo qis cov khoom chip vim muaj kev ua qias tuaj ntawm cov khoom me me. Ntxiv mus, cov foob ib txwm muaj tau tso tawm ntau yam organic impurities thaum lub sijhawm kub siab, ua rau cov khoom siv semiconductor paug thiab ua rau cov khoom tsis ruaj khov. Tom qab hloov lawv nrog cov foob perfluoroelastomer uas peb lub tuam txhab tsim, qhov kev ua haujlwm ruaj khov ntawm cov khoom siv tau zoo dua qub. Tom qab ib xyoos ntawm kev saib xyuas kev ua haujlwm tas mus li, cov foob tsis qhia txog kev xeb lossis laus, tswj tau sab hauv huv si, thiab ua rau cov khoom chip nce ntxiv los ntawm 80% mus rau ntau dua 95%. Qhov no tau ua tiav ua tsaug rau cov foob perfluoroelastomer tiv taus tshuaj lom neeg zoo heev, cov yam ntxwv tsis muaj nag, thiab cov khoom zoo heev, ua rau muaj txiaj ntsig zoo rau lub tuam txhab.

Xaus Lus: Hauv kev lag luam tsim khoom semiconductor, uas siv zog rau qhov tseeb thiab huv si, cov roj hmab tshwj xeeb ua lub luag haujlwm tseem ceeb. Cov roj hmab tshwj xeeb xws li fluoropolymer thiab perfluoroelastomer, nrog lawv cov kev ua tau zoo tshaj plaws, suav nrog kev tswj hwm nruj ntawm cov nag, muab kev sib khi txhim khu kev qha rau cov khoom siv tsim khoom semiconductor, pab kev lag luam txuas ntxiv mus rau qib siab dua.

Lub sijhawm tshaj tawm: Lub Kaum Hli-17-2025