Kev Taw Qhia:

Koj puas tau xav txog tias dab tsi ua rau koj lub tsheb sab hauv qhuav zoo thaum nag los rau ntawm lub ru tsev? Cov lus teb yog nyob rau hauv cov khoom siv hu ua Ethylene Propylene Diene Monomer (EPDM) roj hmab. Ua tus saib xyuas kev lag luam niaj hnub no, EPDM sib xyaw ua ke rau hauv peb lub neej los ntawm nws qhov kev tiv thaiv huab cua zoo heev thiab kev kaw lub hau. Tsab xov xwm no txhais cov thev naus laus zis tom qab "roj hmab ntev" no.

1. EPDM Roj Hmab yog dab tsi?

Kev Txheeb Xyuas Tshuaj:

EPDM yog ib qho polymer uas tau tsim los ntawm kev sib xyaw ua ke ntawm ethylene (E), propylene (P), thiab me me ntawm diene monomer (D). Nws cov qauv "ternary" tshwj xeeb muab ob qho txiaj ntsig:

-

Ethylene + Propylene: Tsim ib lub pob txha caj qaum uas tiv taus kev laus thiab kev xeb tshuaj lom neeg

-

Diene Monomer: Qhia txog cov chaw sib txuas rau kev sib xyaw ua ke thiab elasticity

Cov Ntsiab Lus Tseem Ceeb ntawm Kev Ua Haujlwm:

Huab Cua Tiv Thaiv Vaj Ntxwv: Tiv taus cov duab UV, ozone, thiab qhov kub thiab txias heev (-50 ° C txog 150 ° C)

Kws Tshaj Lij Tiv Thaiv Kev Laus: Lub neej ua haujlwm ntawm 20-30 xyoo

Tus Saib Xyuas Sealing: Cov pa roj tsawg permeability, siab resilience

Eco Champion: Tsis muaj tshuaj lom, tsis muaj ntxhiab, thiab siv tau dua tshiab

2. Qhov chaw uas koj ntsib EPDM txhua hnub

Xwm Txheej 1: "Tus Kws Tshwj Xeeb Txog Kev Sib Nqus" ntawm Kev Lag Luam Tsheb

-

Cov Qhov Rai Seal: Lub hauv paus thaiv tiv thaiv dej, suab nrov, thiab hmoov av

-

Cov Txheej Txheem Cav: Cov kav dej txias thiab cov kav dej turbocharger (ua haujlwm tau kub heev)

-

Cov Pob Roj Teeb EV: Cov ntsaws ruaj ruaj tiv thaiv dej rau kev nyab xeeb ntawm lub zog hluav taws xob siab

-

Cov Txoj Kev Sunroof: tiv taus UV rau kev ua tau zoo kaum xyoo

Cov ntaub ntawv: Lub tsheb nruab nrab siv 12kg ntawm EPDM, suav txog >40% ntawm tag nrho cov khoom siv roj hmab

Xwm Txheej 2: Kev Tsim Kho "Kev Tiv Thaiv Huab Cua"

-

Cov ntaub thaiv ru tsev: Cov khoom siv tseem ceeb rau cov txheej txheem ru tsev ib txheej (30 xyoo lub neej)

-

Cov Gaskets Phab Ntsa: Tiv taus cua hlob thiab thermal expansion

-

Cov Nroj Tsuag Hauv Av: Kev tiv thaiv zoo tshaj plaws tiv thaiv kev nkag mus rau hauv av

Xwm Txheej 3: Tsev Neeg "Tus Khub Uas Ntshai"

-

Cov Khoom Siv Hluav Taws Xob: Cov qhov rooj ntawm lub tshuab ntxhua khaub ncaws, cov gaskets ntawm lub tub yees

-

Cov Chaw Ua Si: Cov hmoov sib tw uas zoo rau ib puag ncig

-

Cov Khoom Ua Si Rau Menyuam: Cov khoom siv roj hmab uas muaj kev nyab xeeb

3. Kev Hloov Pauv EPDM: Txij Li Qhov Yooj Yim Mus Rau Cov Qauv Ntse

1. Kev Txhim Kho Nanotechnology

Cov khoom ntxiv Nanoclay/silica ua rau muaj zog ntxiv 50% thiab tiv taus kev sib txhuam ob npaug (siv rau hauv Tesla Model Y roj teeb foob).

2. Kev Hloov Pauv Ntsuab

-

EPDM uas yog bio-based: DuPont's 30% cov monomers uas yog los ntawm cov nroj tsuag

-

Cov Khoom Uas Tsis Muaj Halogen Uas Ua Rau Hluav Taws Kub Tawm: Ua Tau Raws Li EU RoHS 2.0 tus qauv

-

Kev Siv Rov Qab Ua Dua Tshiab: Michelin ua tiav 100% cov foob rov ua dua tshiab

3. EPDM teb tau zoo

"EPDM uas kho tau tus kheej" uas tsim los ntawm chav kuaj: Cov microcapsules tso cov tshuaj kho thaum puas lawm (yav tom ntej yuav muaj peev xwm ua rau lub foob pob ntawm lub dav hlau).

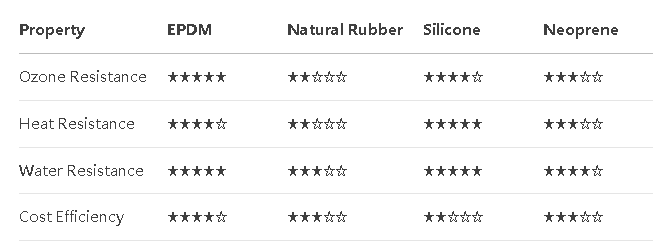

4. EPDM vs. Lwm Cov Roj Hmab: Kev Ua Tau Zoo Sib Tw

Lus Cim: EPDM yeej tag nrho rau kev tiv taus huab cua thiab tus nqi, ua rau nws yog qhov kev xaiv zoo tshaj plaws rau cov ntsaws ruaj ruaj sab nraum zoov

5. Cov Qauv Kev Lag Luam: EVs Ua Rau EPDM Tshiab

Kev loj hlob ntawm lub tsheb fais fab ua rau EPDM nce qib:

-

Kev Sib Txuas Hluav Taws Xob Siab: Cov pob roj teeb xav tau 1000V+ cov ntsaws ruaj ruaj

-

Kev Sib Nyhav: Qhov ceev ntawm EPDM ua npuas ncauj txo qis rau 0.6g / cm³ (piv rau 1.2g / cm³ tus qauv)

-

Kev Tiv Thaiv Kev Xeb ntawm Cov Txias: Cov kua txias glycol tshiab ua kom cov roj hmab laus sai dua

Kev Kwv Yees Lag Luam: Kev lag luam thoob ntiaj teb EPDM tsheb yuav tshaj $ 8 billion los ntawm 2025 (Grand View Research)

6. Cov Lus Tseeb Zoo: EPDM "Cov Haujlwm Uas Tsis Yooj Yim"

-

Cov Ntiv Tes Saum Ntuj: Cov Ntiv Tes Saum Ntuj ISS tswj tau kev ncaj ncees rau 20+ xyoo

-

Cov Qhov Av Hauv Qab Dej: Cov Choj Hong Kong-Zhuhai-Macao uas tau tsim los rau kev pabcuam 120 xyoo

-

Kev Tshawb Fawb Polar: Cov khoom siv tseem ceeb rau -60 ° C Antarctic chaw nres tsheb foob

Xaus Lus: Lub Neej Yav Tom Ntej Ruaj Khov ntawm Ib Tug Neeg Sib Tw Uas Tsis Tau Paub Zoo

Tau ntau tshaj ib nrab xyoo pua, EPDM tau ua pov thawj tias thev naus laus zis tsis yog nyob rau hauv qhov pom kev tab sis nyob rau hauv kev daws teeb meem hauv ntiaj teb tiag tiag. Thaum kev tsim khoom thoob ntiaj teb tig mus rau ntsuab, EPDM qhov rov ua dua tshiab thiab lub neej ntev ua rau nws tseem ceeb rau kev lag luam ncig. EPDM tiam tom ntej ua haujlwm yuav thawb cov ciam teb kev ua tau zoo, txuas ntxiv tiv thaiv txhua yam los ntawm lub neej txhua hnub mus rau qhov chaw sab nraud.

Lub sijhawm tshaj tawm: Lub Xya Hli-09-2025