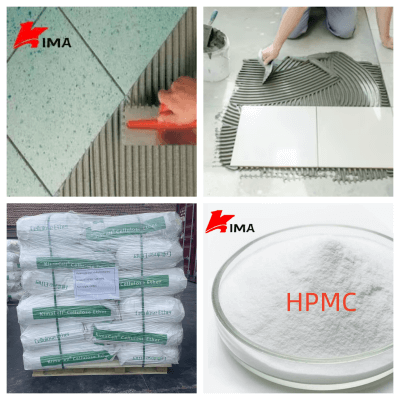

Hydroxypropyl Methylcellulose (HPMC) is a non-ionic cellulose ether that is widely used in building materials, especially in tile adhesives. HPMC has become an indispensable additive in modern building decoration by improving the construction performance, water retention, and bonding strength of tile adhesives.

1. Improve construction performance

1.1. Improve workability

HPMC has good lubrication and adhesion. Adding it to tile adhesive can significantly improve the workability of mortar, making it easier to scrape and smooth, and enhance the operating efficiency and construction quality of construction workers.

1.2. Prevent sagging

When tile adhesive is applied on a vertical surface, it is easy to sag due to its own weight. HPMC effectively improves the anti-sagging property of the adhesive through its thickening and thixotropic properties, so that the tiles can maintain a stable position after paving and prevent slippage.

2. Enhance water retention

2.1. Reduce water loss

HPMC has excellent water retention performance. It can significantly reduce the rapid evaporation of water or absorption by the base layer in tile adhesive, effectively prolong the open time and adjustment time of the adhesive, and provide construction personnel with greater operational flexibility.

2.2. Promote cement hydration reaction

Good water retention helps cement to fully hydrate and form more hydration products, thereby enhancing the bonding strength and durability of tile adhesive.

3. Improve bonding force and strength

3.1. Improve bonding interface structure

HPMC forms a fine polymer network structure in the adhesive, which enhances the bonding performance between tile adhesive and tiles and the base layer. Whether it is absorbent tiles or tiles with low water absorption (such as vitrified tiles and polished tiles), HPMC can provide stable bonding strength.

3.2. Enhance crack resistance and flexibility

The polymer structure of HPMC makes tile adhesive have a certain flexibility, which can adapt to the slight deformation or thermal expansion and contraction of the base layer, and reduce quality problems such as hollowing and cracking caused by stress concentration.

4. Improve construction adaptability

4.1. Adapt to various construction environments

Under adverse climatic conditions such as high temperature, dryness or strong wind, ordinary tile adhesives tend to dry too quickly, resulting in bonding failure. HPMC can effectively delay water loss due to its good water retention and film-forming properties, making tile adhesives adapt to normal construction in various environments.

4.2. Applicable to a variety of substrates

Whether it is cement mortar leveling layer, concrete slab, old tile surface or gypsum substrate, tile adhesives with HPMC added can provide reliable bonding performance, expanding its application range.

5. Environmental protection and safety

HPMC is a green and environmentally friendly material that is non-toxic, odorless, non-flammable, and will not cause harm to the environment or human health. It does not release harmful substances during construction, which is in line with the development concept of modern green buildings.

6. Economic and long-term effectiveness

Although the cost of HPMC is slightly higher than that of traditional additives, it significantly improves the performance of tile adhesives, reduces rework rate and material waste, and has extremely high economic benefits in the long run. High-quality tile adhesives mean less maintenance, longer service life and better building effects.

7. Synergy with other additives

HPMC can be used in conjunction with a variety of additives, such as Redispersible Polymer Powders (RDP), starch ether, water retaining agent, etc., to further optimize the performance of tile adhesives. For example, when used with RDP, it can simultaneously improve flexibility and bonding strength; when used with starch ether, it can further improve water retention and construction smoothness.

HPMC plays an important role in tile adhesives in many aspects. Its main benefits include improving construction performance, enhancing water retention, improving adhesion, improving anti-sagging ability, and adapting to a variety of substrates and environments. As a key additive for modern tile paving construction, HPMC not only meets the diverse needs of current construction, but also promotes technological progress and green development in the tile adhesive industry.

Post time: Jun-24-2025