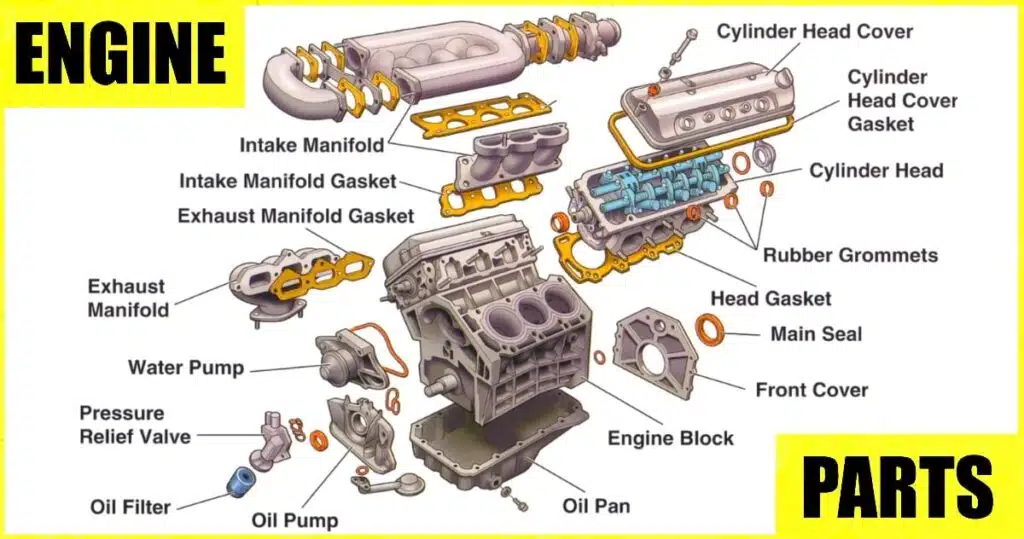

In industrial production and automotive manufacturing, sealing technology is critical to ensuring the reliable operation of equipment. Recently, a dual-connector seal featuring innovative design and excellent performance has entered the market, offering the industry a new sealing solution and sparking widespread attention. At the same time, a detailed image showcasing the engine and its components has been widely shared online, further enhancing people’s understanding of engine structure and the application of sealing components.

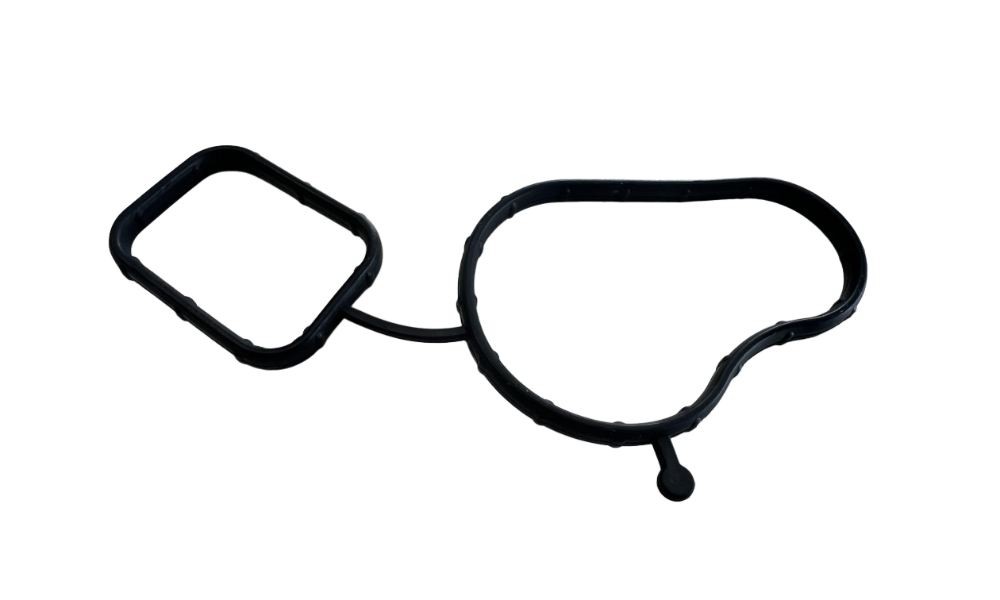

1. Product Appearance and Material Properties

The dual-connector seal consists of two connected rubber rings: one side is a square ring, while the other side is a large elliptical ring with a small dot at the end. This design not only achieves structural innovation but also fully considers functional requirements in real installation and usage scenarios. It is made of high-quality rubber and processed through advanced vulcanization technology. The rubber material itself has excellent elasticity, wear resistance, and corrosion resistance. The vulcanization process further optimizes its molecular structure, ensuring that it maintains stable physical properties within a temperature range of -40°C to 150°C and in high-pressure, chemically complex environments, effectively preventing aging, deformation, and other issues, ensuring long-lasting sealing performance.

2. Core Functions and Application Fields

(a) Exceptional Sealing Performance

In both mechanical and automotive equipment, liquid leakage is a key factor affecting normal operation. Thanks to its unique shape and high-quality rubber material, the dual-connector seal can tightly fill the small gaps between components, forming a reliable sealing barrier. For example, in automotive engines, a cylinder head gasket is needed between the cylinder head and the cylinder block to prevent coolant and engine oil leakage. The square ring part of the dual-connector seal can precisely adapt to similar interfaces, preventing oil and coolant leakage and mixing, ensuring stable engine operation under high temperature, high pressure, and vibration, maintaining good lubrication and cooling effects, and extending engine life. In hydraulic systems of mechanical equipment, the elliptical ring part tightly fits the connecting parts of hydraulic cylinders and pumps, maintaining sealing under high-pressure oil impact due to its excellent elastic deformation ability, ensuring efficient operation of hydraulic systems and enhancing mechanical performance and operational precision.

(b) Connection and Fixation Function

The dual-ring structure of the dual-connector seal gives it both sealing and connection functions. In the assembly of automotive components, such as the connection between the intake manifold and the engine block, the seal is installed at the interface, not only providing sealing to prevent leaks but also enhancing the tightness of the connection through elastic deformation and structural features, reducing the risk of failure caused by loosening. In industrial pipeline systems, it simplifies the pipe connection process, replacing the traditional complicated bolt and nut connection methods, enabling rapid pipe sealing and fixation, reducing leakage risks, lowering maintenance costs and complexity, and improving material transport efficiency and safety.

3. Significant Performance Advantages

(a) Wide Temperature Range Adaptability

Industrial equipment and automotive mechanics often face extreme temperature environments. The rubber material of the dual-connector seal is specially formulated to maintain stable performance and sealing effectiveness within a temperature range of -40°C to 150°C. In cold winters, it can quickly recover its elasticity to ensure normal lubrication of automotive engines, while in high-temperature environments, it does not soften or deform, continuously protecting internal components and fluids.

(b) High Wear Resistance and Aging Resistance

Frequent movement of equipment and long-term vehicle operation subject seals to continuous friction and mechanical stress. The dual-connector seal uses high-quality rubber material with a special surface treatment to reduce friction, slowing wear. Additionally, the anti-aging additives added to the seal effectively resist the effects of UV rays, ozone, and other environmental factors. Even after long-term complex mechanical movement, it retains good elasticity and sealing performance, reducing the frequency of equipment maintenance and replacement, lowering operational costs, and improving production efficiency.

(c) Wide Chemical Resistance

In industrial production and automotive operation, seals are exposed to various chemical agents. The rubber material of the dual-connector seal is designed to have excellent resistance to common automotive fluids, industrial hydraulic oils, lubricants, and other substances. It does not undergo significant physical or chemical changes even after prolonged exposure, preventing fluid leakage and corrosion of equipment components, ensuring stable operation of equipment in complex chemical environments.

4. Position and Function of Dual-Connector Seals in Engines

From the image, it can be seen that the dual-connector seal is primarily installed between the intake manifold and the engine block, as well as between the cylinder block and the cylinder head. In these critical areas, the dual-connector seal plays a vital role in sealing. The square ring part fits tightly at the connection between the cylinder head and the cylinder block, effectively preventing the leakage of engine oil and coolant and ensuring that fluids inside the engine maintain normal lubrication and cooling functions under high temperatures, high pressures, and vibration. The elliptical ring part is installed between the intake manifold and the cylinder block, ensuring the sealing of the intake process so that air or combustible mixtures can enter each cylinder uniformly and accurately, thereby ensuring engine combustion efficiency and power output. This intuitive presentation not only allows more people to gain a deeper understanding of the dual-connector seal but also provides valuable reference material for industry professionals, fostering the exchange and innovation of sealing technologies.

Post time: May-21-2025