7 AM, the city awakens in a light drizzle. Mr. Zhang, as usual, walks towards his electric vehicle, ready for another day’s commute. Raindrops strike the charging pile, sliding down its smooth surface. He deftly flips open the charging port cover, the rubber seal slightly deforming to form a watertight barrier – the silent, daily duty of the charging pile rubber gasket begins. This unassuming rubber component acts like a quiet sentinel, reliably safeguarding the safety of every charge.

I. The Relentless Guardian: The Daily Mission of the Rubber Gasket

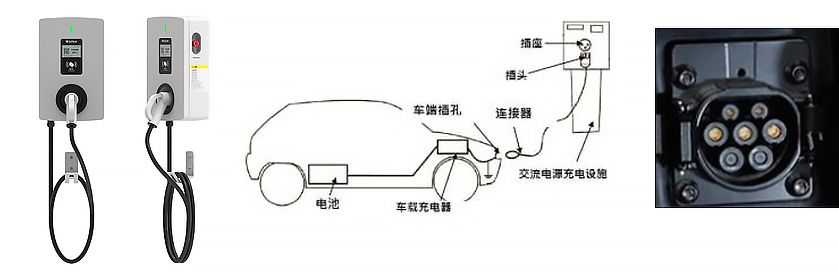

- First Line of Defense Against Water and Dust: The charging gun socket is the gateway to sensitive electronics. The rubber gasket’s primary task is to act as both an “umbrella” and a “shield,” sealing the socket opening when not in use. Whether it’s a sudden downpour, high-pressure spray during car washing, or the sandstorms common in northern regions, the gasket leverages its flexibility to conform tightly to the port edges, creating a physical barrier that keeps out anything that could cause short circuits or corrosion.

- The “Safety Lock” Against Foreign Objects: An exposed charging port is like an open “little cave.” Curious children might insert metal pieces or keys; roadside pebbles could accidentally roll in. The rubber gasket acts like a diligent guard, effectively blocking these unexpected “intruders,” preventing scratches, short circuits, or even more serious accidents to the internal metal contacts.

- Buffer Against Extreme Temperatures: On freezing winter mornings, metal interfaces are icy cold; on scorching summer afternoons, the charging pile surface can exceed 60°C (140°F). Thanks to its excellent weather resistance and elasticity, the rubber gasket expands and contracts smoothly through thermal cycles, avoiding seal failure or structural damage caused by differing thermal expansion rates of metal parts, maintaining reliable protection.

II. The Unsung Hero of Safety: Value Beyond Waterproofing

- Reliable Barrier for Electrical Insulation: Charging piles carry high-voltage DC electricity. The rubber gasket itself is an excellent insulator. When the cover is closed, it provides an additional crucial layer of electrical isolation alongside its physical barrier against water and dust. This insulation significantly reduces the risk of external metal parts becoming accidentally live (especially in humid conditions) when not charging, adding an extra safety net.

- Preventing Accidental Electric Shock: Imagine a wet hand accidentally touching the exposed edge of the charging port – a potentially dangerous situation. The rubber gasket covering the metal edges around the port acts like a “protective sleeve,” drastically reducing the chance of users or passersby (especially children) accidentally touching live metal parts near the charging pile, providing vital protection for personal safety.

- Extending Core Component Lifespan: Long-term intrusion of moisture, salt spray (in coastal areas), and dust accelerates the oxidation, corrosion, and aging of the charging pile’s internal metal contacts and electronic components. The persistent seal provided by the rubber gasket acts like a protective umbrella for these expensive “heart” components, significantly delaying performance degradation, ensuring charging efficiency, reducing equipment failure rates, and ultimately extending the overall lifespan of the charging pile.

III. Small Size, Big Science: The Technology Within the Rubber

- Why Rubber is Essential?

- King of Flexible Sealing: Rubber’s unique molecular structure gives it exceptional elastic deformation ability. This allows the gasket to conform tightly to the edges of various charging port shapes, filling tiny imperfections through its own deformation to achieve a leak-proof seal – a core advantage unattainable by metal or rigid plastics.

- Built to Last: Rubber formulations specifically developed for charging pile gaskets (like EPDM – Ethylene Propylene Diene Monomer, or CR – Chloroprene Rubber) possess outstanding resistance to UV rays (anti-sun), ozone (anti-aging), extreme temperatures (-40°C to +120°C / -40°F to 248°F), and chemical agents (like car exhaust, acid rain). This ensures long-term performance in harsh outdoor environments without becoming brittle, cracking, or permanently deforming.

- The Stable Guardian: High-quality rubber maintains stable physical properties and elasticity over long-term use, avoiding seal failure due to loosening or deformation after repeated opening/closing, providing durable and reliable protection.

- Design Details Matter:

- Precise Contour: The gasket’s shape is not arbitrary. It must precisely match the geometric shape of the charging pile port (round, square, or custom), often featuring specific lips, grooves, or ridges at the edges to achieve optimal compression sealing.

- Just-Right Elasticity: Too weak, it won’t seal; too strong, it’s hard to open and wears faster. Engineers adjust rubber hardness (Shore hardness) and structural design (e.g., internal support skeleton) to ensure sealing force while aiming for smooth operation and durability.

- Secure Installation: Gaskets are typically firmly attached to the charging pile or charging gun via snap-fit embedding, adhesive bonding, or co-molding with the cover itself. This prevents them from being easily pulled off or displaced during use, ensuring continuous protection.

IV. Selection and Maintenance: Keeping Your “Rubber Guardian” Effective Longer

- Choosing Wisely:

- OEM Match is Best: When replacing a gasket, prioritize Original Equipment Manufacturer (OEM) parts specified by the charging pile brand or certified third-party products that strictly comply with its specifications. Minute differences in size, shape, or hardness can compromise sealing.

- Check Material Specs: Look for material information in the product description (e.g., EPDM, Silicone). High-quality material is fundamental for long-term durability. Avoid inferior recycled rubber prone to aging and cracking.

- Initial Sensory Check: Good rubber parts feel flexible and resilient, have no strong pungent odor (inferior rubber might), and have a smooth, fine surface free of obvious impurities, cracks, or burrs.

- Simple Daily Care:

- Clean Properly: Regularly wipe the gasket surface and the contacting port edge with a clean, soft cloth or sponge dampened with water to remove dust, sand, bird droppings, etc. NEVER use gasoline, strong acids/bases, or organic solvents (like alcohol – use with caution). These can severely corrode rubber, causing swelling, cracking, or hardening.

- Inspect Frequently: Make it a habit to check the rubber gasket whenever you open/close the cover:

- Are there obvious cracks, cuts, or tears?

- Is it permanently deformed (e.g., flattened and won’t spring back)?

- Is the surface sticky or powdery (signs of severe aging)?

- When closed, does it still feel tightly fitted, not loose?

- Lubricate Sparingly (If Needed): If opening/closing feels stiff or overly resistant, ALWAYS consult the manual or manufacturer first. Only if explicitly recommended, apply a tiny amount of dedicated rubber protectant/silicone-based grease to hinges or sliding points. Avoid getting grease directly on the gasket’s sealing surface, as it attracts dirt and breaks the seal. NEVER use general-purpose lubricants like WD-40, as their solvent content damages rubber.

V. Outlook: The Big Future of a Small Part

As the number of new energy vehicles continues to surge (by the end of 2024, China’s pure EV ownership alone surpassed 20 million), the reliability and safety requirements for charging piles, the core infrastructure, are increasing. Though small, rubber gasket technology is also evolving:

- Material Advancements: Developing new synthetic rubbers or specialty elastomers that are more resistant to extreme temperatures (deep freeze and intense heat), more durable against aging, and more environmentally friendly (halogen-free, flame retardant).

- Smart Integration: Exploring integrating micro-switch sensors within the gasket to send alerts to user apps or charging management systems if the cover isn’t properly closed, enhancing safety monitoring.

- Design Optimization: Using simulation and testing to continuously refine gasket structure, aiming for longer lifespan, more convenient operation (e.g., easy one-handed opening), and lower manufacturing costs while ensuring sealing performance.

As night falls and city lights illuminate, countless electric vehicles sit quietly beside charging piles. In the darkness, rubber gaskets silently perform their duty, sealing out moisture, blocking dust, and guarding the intricate circuits within the ports. They are the charging pile’s “bodyguards,” building an invisible yet solid line of defense against every onslaught of weather and the wear of daily use.

The warmth of technology often lies in the most unassuming details. This small rubber gasket is a tiny footnote of safety and reliability in the grand narrative of the new energy era. It reminds us that true peace of mind is often found in these meticulously designed, everyday guardians.

Post time: Aug-12-2025