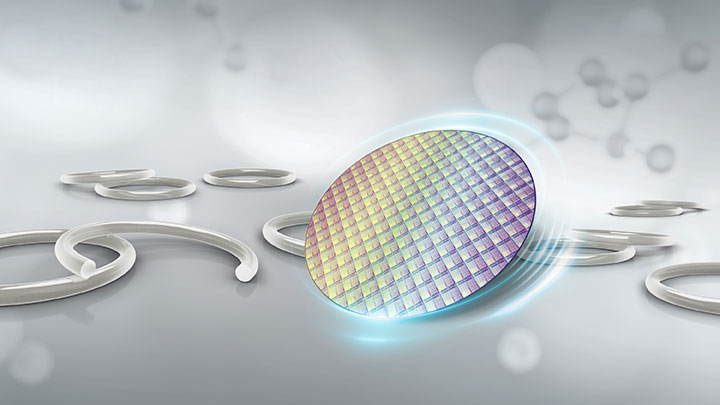

Mu gawo laukadaulo wapamwamba wopanga zinthu zopangidwa ndi semiconductor, gawo lililonse limafuna kulondola kwambiri komanso ukhondo. Zisindikizo zapadera za rabara, monga zinthu zofunika kwambiri zomwe zimaonetsetsa kuti zida zopangira zikugwira ntchito bwino komanso kusunga malo opangira zinthu oyera kwambiri, zimakhudza mwachindunji phindu ndi magwiridwe antchito a zinthu zopangidwa ndi semiconductor. Lero, tifufuza momwe zisindikizo zapadera za rabara monga fluororubber ndi perfluoroelastomer zimagwirira ntchito yofunika kwambiri popanga zinthu zopangidwa ndi semiconductor.

I. Zofunikira Zokhwima za Malo Opangira Ma Semiconductor

Kupanga ma semiconductor nthawi zambiri kumachitika m'zipinda zoyera, komwe kumafunika kuyeretsa chilengedwe kumakhala kokwera kwambiri. Ngakhale tinthu tating'onoting'ono ta zinthu zodetsa zimatha kuyambitsa ma chip short circuits kapena zolakwika zina pakugwira ntchito. Kuphatikiza apo, njira yopangirayi imaphatikizapo kugwiritsa ntchito mankhwala osiyanasiyana owononga kwambiri, monga ma photoresists, ma etching solutions, ndi madzi oyeretsera. Kuphatikiza apo, njira zina zimakumana ndi kusintha kwakukulu kwa kutentha ndi kuthamanga kwa magazi. Mwachitsanzo, njira zoetching ndi ion implantation zimapanga kutentha kwambiri ndi kupsinjika mkati mwa zida. Kuphatikiza apo, ma precipitates ochokera ku zisindikizo amatha kukhala ndi vuto lalikulu pakupanga ma semiconductor. Ngakhale ma precipitates ochepa amatha kuipitsa zinthu za semiconductor kapena njira, kusokoneza kulondola kwa njira yopangira.

II. Ntchito Zofunika Kwambiri za Zisindikizo Zapadera za Rubber

1. Kuletsa Kuipitsidwa ndi Tinthu Tating'onoting'ono: Zomatira zapadera za rabara zimaletsa fumbi, zinyalala, ndi tinthu tina tomwe timachokera ku chilengedwe chakunja kuti tisalowe mu chipangizocho, zomwe zimapangitsa kuti chilengedwe chikhale choyera. Potengera zomatira za perfluoroelastomer mwachitsanzo, pamwamba pake posalala pamakana kuyamwa tinthu tating'onoting'ono. Kusinthasintha kwawo kwabwino kumawathandiza kuti azigwirizana bwino ndi zida, ndikupanga chotchinga chodalirika chomatira ndikuwonetsetsa kuti njira yopangira semiconductor ilibe kuipitsidwa ndi tinthu tating'onoting'ono.

2. Kulimbana ndi Kutupa kwa Mankhwala: Zisindikizo monga fluorocarbon ndi perfluoroelastomer zimapereka kukana bwino kwambiri kwa mankhwala omwe amagwiritsidwa ntchito kwambiri popanga semiconductor. Zisindikizo za fluorocarbon zimalimbana ndi mayankho wamba a acidic ndi alkaline ndi organic solvents, pomwe zisindikizo za perfluoroelastomer zimakhala zokhazikika makamaka m'malo omwe amawononga kwambiri okosijeni komanso owononga. Mwachitsanzo, m'njira zonyowa, zisindikizo za perfluoroelastomer zimatha kupirira kukhudzana kwa nthawi yayitali ndi mayankho okhala ndi asidi ambiri popanda dzimbiri, zomwe zimaonetsetsa kuti zidazo zikutsekedwa komanso kukhazikika.

3. Kusinthasintha kwa Kutentha ndi Kupanikizika: Zipangizo zopangira semiconductor zimakhala ndi kusinthasintha kwa kutentha ndi kupanikizika pafupipafupi zikagwiritsidwa ntchito. Zisindikizo zapadera za rabara zimafuna kukana kutentha kwambiri komanso kotsika, komanso kusinthasintha kwabwino komanso kukana kupanikizika. Zisindikizo za fluororabber zimasunga kusinthasintha kwabwino komanso kutseka mkati mwa kutentha kwina, kusintha kutentha panthawi zosiyanasiyana zokonzera. Zisindikizo za perfluoroelastomer, kumbali ina, sizimangopirira kutentha kwambiri komanso zimakana kukhala zolimba kapena zofooka pa kutentha kochepa, kusunga magwiridwe antchito odalirika komanso kuonetsetsa kuti zida zikugwira ntchito bwino pansi pa zovuta zosiyanasiyana zogwirira ntchito.

4. Kulamulira Kuopsa kwa Mvula: Kulamulira mvula kuchokera ku zisindikizo ndikofunikira kwambiri popanga zinthu zopangidwa ndi ...

III. Zofunikira pa Magwiridwe Antchito ndi Zofunikira Zosankha Zisindikizo Zapadera za Rubber

1. Kapangidwe ka Ukhondo: Kusakhazikika pamwamba, kusasinthasintha, ndi kutulutsidwa kwa tinthu ndi zizindikiro zazikulu za zisindikizo. Zisindikizo zokhala ndi kusakhazikika pang'ono pamwamba sizimakhudzidwa kwambiri ndi tinthu tating'onoting'ono, pomwe kusakhazikika pang'ono kumachepetsa chiopsezo cha mpweya wochokera ku zisindikizo m'malo otentha kwambiri. Mukasankha zisindikizo, perekani patsogolo zinthu zomwe zili ndi mankhwala apadera pamwamba omwe amapereka kusakhazikika pang'ono komanso kutulutsa tinthu tating'onoting'ono. Mwachitsanzo, zisindikizo za perfluoroelastomer zotsukidwa ndi plasma zimapereka malo osalala komanso zimachepetsa kusakhazikika. Komanso, samalani ndi mawonekedwe a kutulutsa kwa chisindikizocho ndikusankha zinthu zomwe zayesedwa kwambiri kuti zitsimikizire kuti sizitulutsa mpweya woipa m'malo opangira semiconductor.

2. Kugwirizana kwa mankhwala: Sankhani zinthu zoyenera za rabara kutengera zinthu zomwe zimapezeka popanga semiconductor. Mitundu yosiyanasiyana ya fluoroelastomer ndi perfluoroelastomer imakhala ndi kukana kosiyanasiyana kwa mankhwala osiyanasiyana. Pazinthu zomwe zimaphatikizapo ma asidi amphamvu ochulukitsa okosijeni, ma seal a perfluoroelastomer ochulukitsa okosijeni ayenera kusankhidwa. Pazinthu zomwe zimakhudza zosungunulira zachilengedwe, ma seal a fluoroelastomer akhoza kukhala njira yotsika mtengo kwambiri.

3. Makhalidwe a thupi: Izi zikuphatikizapo kuuma, elastic modulus, ndi compression set. Zisindikizo zokhala ndi kuuma pang'ono zimathandizira kuti chisindikizo chikhale bwino komanso zimathandiza kuyika ndi kuchotsa. Elastic modulus ndi compression set zimasonyeza kukhazikika kwa chisindikizo panthawi yamavuto a nthawi yayitali. M'malo otentha kwambiri komanso opanikizika kwambiri, zisindikizo zokhala ndi compression yochepa ziyenera kusankhidwa kuti zitsimikizire kuti zisindikizo zimagwira ntchito bwino kwa nthawi yayitali komanso mokhazikika.

IV. Kusanthula Nkhani Yogwiritsidwa Ntchito Mwaluso

Kampani yodziwika bwino yopanga zinthu zoyezera magetsi (semiconductor) inali ndi dzimbiri komanso kukalamba kwa zisindikizo za rabara zomwe zimagwiritsidwa ntchito popanga zinthu zoyezera magetsi (etching) pamakina ake opangira zinthu zoyezera magetsi (chip line). Izi zinapangitsa kuti zisindikizo zamkati zituluke, zomwe zinakhudza momwe zinthu zimagwirira ntchito komanso kuchepetsa kwambiri kuchuluka kwa zisindikizo chifukwa cha kuipitsidwa kwa tinthu tating'onoting'ono. Kuphatikiza apo, zisindikizo zachikhalidwe zinatulutsa zinthu zambiri zodetsa zachilengedwe panthawi yotentha kwambiri, zomwe zinaipitsa zinthu za semiconductor ndikupangitsa kuti zinthu zisagwire bwino ntchito. Pambuyo pozisintha ndi zisindikizo za perfluoroelastomer zopangidwa ndi kampani yathu, kukhazikika kwa magwiridwe antchito a zidazo kunakula kwambiri. Pambuyo pa chaka choyang'anira ntchito mosalekeza, zisindikizozo sizinawonetse zizindikiro za dzimbiri kapena kukalamba, kusunga mkati mwa nyumbayo kukhala woyera kwambiri, ndikuwonjezera kuchuluka kwa zisindikizo kuchokera pa 80% mpaka 95%. Izi zinatheka chifukwa cha kukana mankhwala kwa zisindikizo za perfluoroelastomer, kuchepa kwa mvula, komanso makhalidwe abwino kwambiri, zomwe zinapangitsa kuti kampaniyo ipindule kwambiri pazachuma.

Pomaliza: Mu makampani opanga zinthu za semiconductor, omwe amayesetsa kukhala olondola kwambiri komanso aukhondo, zisindikizo zapadera za rabara zimakhala ndi gawo lofunika kwambiri. Zisindikizo zapadera za rabara monga fluoropolymer ndi perfluoroelastomer, zomwe zimagwira ntchito bwino kwambiri, kuphatikizapo kuwongolera kwambiri mvula, zimapereka chisindikizo chodalirika cha zida zopangira zinthu za semiconductor, zomwe zimathandiza makampaniwa kupita patsogolo mpaka pamlingo wapamwamba waukadaulo.

Nthawi yotumizira: Okutobala-17-2025