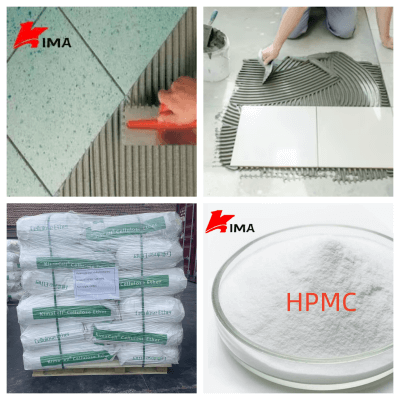

Hydroxypropyl Methylcellulose (HPMC)imhando ye non-ionic cellulose ether inoshandiswa zvakanyanya muzvinhu zvekuvaka, kunyanya muma tile adhesives. HPMC yave chinhu chakakosha mukushongedza zvivakwa zvemazuva ano nekuvandudza mashandiro ekuvaka, kuchengetedza mvura, uye simba rekubatanidza ma tile adhesives.

1. Kuvandudza mashandiro ekuvaka

1.1. Kuvandudza kushanda zvakanaka

HPMC ine mafuta ekuzora uye kunamira zvakanaka. Kuiisa pane tile glue kunogona kuvandudza kushanda kwemota, zvichiita kuti zvive nyore kukwenya nekutsvedzerera, uye kuwedzera kushanda zvakanaka uye kunaka kwevashandi vekuvaka.

1.2. Dzivisa kudonha

Kana glue yemataira yakaiswa pamusoro wakamira, zviri nyore kudonha nekuda kwehuremu hwayo. HPMC inovandudza zvinobudirira hunhu hweglue hunodzivirira kudonha kuburikidza nekukora kwayo uye hunhu hwethixotropic, kuitira kuti mataira agone kugara akagadzikana mushure mekugadzika uye kudzivirira kutsvedza.

2. Wedzera kuchengetwa kwemvura

2.1. Deredza kurasikirwa nemvura

HPMC ine simba rakanaka rekuchengetedza mvura. Inogona kuderedza zvakanyanya kupwa kwemvura nekukurumidza kana kunyudzwa nechikamu chepasi chenamira yemataira, zvichiita kuti nguva yekuvhurika uye nguva yekugadzirisa inamira iwedzere, uye kupa vashandi vekuvaka mukana wekushanda zviri nani.

2.2. Kurudzira kunyoroveswa kwemvura nesimende

Kuchengeta mvura zvakanaka kunobatsira simende kuti iwane mvura yakakwana uye kugadzira zvinhu zvakawanda zvinopa mvura yakawanda, nokudaro zvichiwedzera simba rekubatanidza uye kugara kwenguva refu kwechinamira chemataira.

3. Kuvandudza simba rekubatana uye simba

3.1. Kuvandudza chimiro chekubatanidza

HPMC inoumba chimiro chakanaka che polymer network mu glue, izvo zvinowedzera mashandiro e bonding pakati pe tile adhesive nema tile ne base layer. Ingave iri ma tile anobata kana ma tile ane mvura shoma inonyudza (senge ma vitrified mataira nema tile akaporishwa), HPMC inogona kupa simba rakasimba re bonding.

3.2. Wedzera kuramba kutsemuka uye kuchinjika

Maumbirwo epolymer eHPMC anoita kuti tile inamire ive nekuchinjika kwakati, izvo zvinogona kuchinjika nekukanganisika kudiki kana kuwedzera kupisa uye kupfupika kwechigadziko, uye kuderedza matambudziko emhando dzakadai sekutsemuka nekutsemuka kunokonzerwa nekuwanda kwestress.

4. Kuvandudza kugona kwekuvaka

4.1. Gadzirira nzvimbo dzakasiyana dzekuvaka

Kana mamiriro ekunze asina kunaka akadai sekupisa kwakanyanya, kuoma kana mhepo ine simba, zvinonamira mataira zvinowanzooma nekukurumidza, zvichikonzera kutadza kubatana. HPMC inogona kunonotsa kurasikirwa nemvura nekuda kwekuchengetedza kwayo mvura zvakanaka uye hunhu hwayo hwekugadzira firimu, zvichiita kuti zvinonamira mataira zvienderane nekuvakwa kwakajairika munzvimbo dzakasiyana-siyana.

4.2. Inoshanda kune akasiyana-siyana ma substrates

Ingava simende inoenzanisa dhaka, kongiri, pamusoro pemataira ekare kana gypsum substrate, zvinonamira mataira zvine HPMC zvinogona kupa mashandiro akavimbika ekubatanidza, zvichiwedzera huwandu hwekushandiswa kwazvo.

5. Kudzivirirwa kwezvakatipoteredza uye kuchengetedzeka

HPMC chinhu chakasvibira uye chine hushamwari kune zvakatipoteredza chisina chepfu, hachinhuwi, hachibati moto, uye hachizokuvadzi nharaunda kana hutano hwevanhu. Hachiburitse zvinhu zvinokuvadza panguva yekuvaka, izvo zvinoenderana nepfungwa yekuvandudzwa kwezvivakwa zvemazuva ano zvegirinhi.

6. Kubudirira kwehupfumi uye kwenguva refu

Kunyangwe mutengo weHPMC wakakwira zvishoma pane wezvinowedzerwa zvechinyakare, zvinovandudza zvakanyanya mashandiro ezvinonamira zvemataira, zvinoderedza mwero wekugadzirisa patsva uye marara ezvinhu, uye zvine mabhenefiti makuru ehupfumi nekufamba kwenguva. Zvinonamira zvemataira zvemhando yepamusoro zvinoreva kusagadziriswa zvakanaka, kugara kwenguva refu uye mhedzisiro iri nani yekuvaka.

7. Kushanda pamwe chete nezvimwe zvinowedzera

HPMC inogona kushandiswa pamwe chete nezvimwe zvinhu zvakasiyana-siyana, zvakaita seUpfu hwePolymer Hunogona Kunyungudutswazve(RDP), starch ether, chinhu chinochengetedza mvura, nezvimwewo, kuti zviwedzere kushanda zvakanaka kwematiles ekunamira. Semuenzaniso, kana ikashandiswa neRDP, inogona kuvandudza kuchinjika uye simba rekubatanidza panguva imwe chete; kana ikashandiswa nestarch ether, inogona kuwedzera kuvandudza kuchengetedza mvura uye kutsetseka kwekuvaka.

HPMC ine basa rakakosha mukunamatira mataira muzvinhu zvakawandaMabhenefiti ayo makuru anosanganisira kuvandudza mashandiro ekuvaka, kusimudzira kuchengetedza mvura, kuvandudza kunamira, kuvandudza kugona kudzivirira kudzika, uye kugadzirisa zvinoenderana nemhando dzakasiyana dzezvinhu uye nharaunda. Sechinongedzo chakakosha pakuvaka mataira emazuva ano, HPMC haingosanganisi chete zvinodiwa zvekuvaka pari zvino, asiwo inokurudzira kufambira mberi kwetekinoroji uye kukura kwezvakatipoteredza muindasitiri yekunamira mataira.

Nguva yekutumira: Chikumi-24-2025