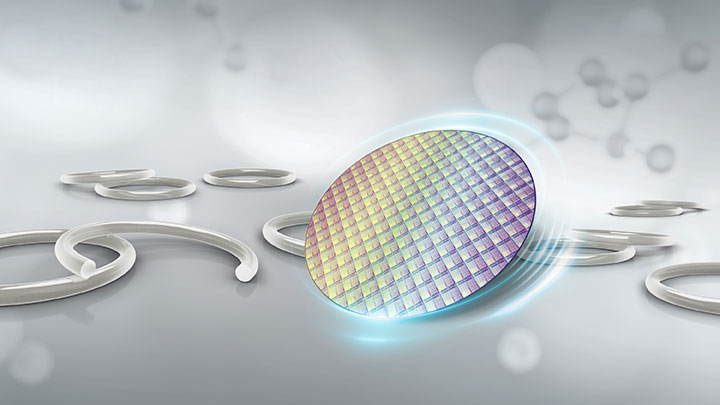

Mubasa repamusoro-soro rekugadzira zvinhu zve semiconductor, danho rega rega rinoda kunyatsojeka uye kuchena kwakanyanya. Zvisimbiso zverabha zvemhando yepamusoro, sezvinhu zvakakosha zvinovimbisa kushanda kwakasimba kwemidziyo yekugadzira uye kuchengetedza nzvimbo yekugadzira yakachena kwazvo, zvine chekuita zvakananga nekubudirira uye mashandiro ezvigadzirwa zve semiconductor. Nhasi, tichaongorora kuti zvisimbiso zverabha zvemhando yepamusoro zvakaita se fluororubber ne perfluoroelastomer zvinoita sei basa rakakosha mukugadzira zvinhu zve semiconductor.

I. Zvinodiwa Zvakasimba zveMamiriro Ekugadzira Makonductor

Kugadzira semiconductors kunowanzoitirwa mumakamuri ekuchenesa, uko zvinodiwa zvekuchena kwezvakatipoteredza zvakanyanya. Kunyangwe zvidimbu zvidiki zvezvinosvibisa zvinogona kukonzera chip short circuits kana zvimwe zvikanganiso zvekushanda. Uyezve, maitiro ekugadzira anosanganisira kushandiswa kwemakemikari akasiyana-siyana anopisa zvakanyanya, akadai se photoresists, etching solutions, uye cleaning fluids. Uyezve, mamwe matanho ekuita anosangana nekuchinja kukuru kwekushisa nekumanikidzwa. Semuenzaniso, maitiro e etching uye ion implantation anogadzira tembiricha yakakwira nekumanikidzwa mukati memidziyo. Uyezve, precipitates kubva mu seals inogona kukanganisa zvakanyanya kugadzirwa kwe semiconductor. Kunyangwe huwandu hushoma hwe precipitates hunogona kusvibisa zvinhu zve semiconductor kana maitiro, zvichikanganisa kururama kwemaitiro ekugadzira.

II. Mabasa Akakosha eZvisimbiso zveRabha zveSpecialty

1. Kudzivirira Kusvibiswa kweZvidimbu: Zvisimbiso zverabha zvemhando yepamusoro zvinodzivirira guruva, tsvina, nezvimwe zvidimbu zvinobva kunze kuti zvisapinde mumidziyo, zvichichengetedza nharaunda yakachena. Tichitora zvisimbiso zveperfluoroelastomer semuenzaniso, pamusoro pazvo panyorova panodzivirira kunyudzwa kwezvidimbu. Kuchinjika kwazvo kunoita kuti zvikwanise kugara zvakanaka mumidziyo, zvichiita kuti pave nechidziviriro chekuvhara uye kuve nechokwadi chekuti maitiro ekugadzira semiconductor haana kusvibiswa nezvikamu.

2. Kudzivirira Kuora Kwemakemikari: Zvisimbiso zvakaita sefluorocarbon neperfluoroelastomer zvinodzivirira zvakanyanya ma reagents emakemikari anoshandiswa mukugadzira semiconductor. Zvisimbiso zveFluorocarbon zvinodzivirira mhinduro dzakajairika dzeacidic nealkaline uye organic solvents, nepo zvisimbiso zveperfluoroelastomer zvakagadzikana zvakanyanya munzvimbo dzemakemikari dzinopisa zvakanyanya uye dzinoparadza. Semuenzaniso, mukuita kwekucheka kwakanyorova, zvisimbiso zveperfluoroelastomer zvinogona kutsungirira kusangana kwenguva refu nemhinduro dzekucheka dzine acidic yakawanda pasina ngura, zvichiita kuti michina ivharwe uye igadzikane.

3. Kugadzirisa Kuchinja-chinja Kwekupisa Nekumanikidzwa: Midziyo yekugadzira semiconductor inosangana nekuchinja-chinja kwekupisa nekumanikidzwa kakawanda panguva yekushanda. Zvisimbiso zverabha zvemhando yepamusoro zvinoda kuramba kupisa kwepamusoro nepasi, pamwe nekusimba uye kuramba kumanikidzwa. Zvisimbiso zveFluororubber zvinochengetedza kusimba uye kusimba mukati memhando yekupisa, zvichichinja-chinja kwekupisa panguva dzakasiyana dzekugadzirisa. Zvisimbiso zvePerfluoroelastomer, kune rumwe rutivi, hazvingomiri chete pakupisa kwakanyanya asiwo zvinoramba kuoma kana kupwanyika pakupisa kwakaderera, zvichichengetedza kushanda kwakavimbika kwekuvhara uye kuve nechokwadi chekushanda kwakajairika kwemidziyo mumamiriro akasiyana-siyana ekushanda akaomarara.

4. Kudzora Njodzi yeMvura: Kudzora mvura inobva muzvisimbiso kwakakosha mukugadzira zvinhu zvakasiyana-siyana. Zvisimbiso zverabha zvakaita sefluoroelastomer neperfluoroelastomer zvinoshandisa nzira dzakagadzirwa zvakanaka uye maitiro ekugadzira kuderedza kushandiswa kwezvinhu zvakasiyana-siyana, nokudaro zvichideredza mukana wekunaya kwetsvina dzakadai semamorekuru madiki eorganic uye maion esimbi panguva yekugadzira. Hunhu uhwu hwekunaya kwemvura shoma hunovimbisa kuti zvisimbiso hazvive chinhu chinogona kukonzera kusvibiswa, zvichichengetedza nharaunda yakachena kwazvo inodiwa pakugadzira zvinhu zvakasiyana-siyana.

III. Zvinodiwa Pakushanda Uye Maitiro Ekusarudza Zvisimbiso Zverabha Zvakanyanya

1. Hunhu Hwakabatana Nekuchena: Kuomarara pamusoro, kushanduka-shanduka, uye kuburitswa kwezvikamu zviratidzo zvikuru zvezvisimbiso. Zvisimbiso zvine kuputika kushoma pamusoro hazviwanzo kuunganidzwa kwezvikamu, nepo kushanduka-shanduka kushoma kunoderedza njodzi yekuburitswa kwegasi reorganic kubva kuzvisimbiso munzvimbo dzinopisa zvakanyanya. Pakusarudza zvisimbiso, isa pamberi zvigadzirwa zvine kurapwa kwakakosha pamusoro izvo zvinopa kushanduka-shanduka kushoma uye kuburitswa kwezvikamu. Semuenzaniso, zvisimbiso zveperfluoroelastomer zvakarapwa neplasma zvinopa nzvimbo yakatsetseka uye zvinoderedza kushanduka-shanduka. Zvakare, teerera kune hunhu hwekuburitswa kwechisimbiso uye sarudza zvigadzirwa zvakaedzwa zvakanyanya kuti uve nechokwadi chekuti hazviburitse hutsi hunokuvadza munzvimbo dzekugadzira semiconductor.

2. Kuenderana kwemakemikari: Sarudza rabha yakakodzera zvichienderana nemakemikari chaiwo anowanikwa panguva yekugadzira semiconductor. Mhando dzakasiyana dzefluoroelastomer neperfluoroelastomer dzine simba rekudzivirira makemikari akasiyana. Kune maitiro ane maacid ane simba re oxidizing, ma perfluoroelastomer ane oxidizing yakawanda anofanira kusarudzwa. Kune maitiro ane organic solvents, ma fluoroelastomer seals anogona kunge ari sarudzo inodhura zvishoma.

3. Hunhu hwemuviri: Izvi zvinosanganisira kuomarara, elastic modulus, uye compression set. Zvisimbiso zvine mwero zvinovimbisa chisimbiso chakanaka ukuwo zvichibatsirawo kuisa nekubvisa. Elastic modulus uye compression set zvinoratidza kugadzikana kwekushanda kwechisimbiso kana chiri mukumanikidzwa kwenguva refu. Munzvimbo dzine tembiricha yakakwira uye kumanikidzwa kwakanyanya, zvisimbiso zvine compression shoma zvinofanirwa kusarudzwa kuti zvive nechokwadi chekuti chisimbiso chinoshanda kwenguva refu uye chakagadzikana.

IV. Kuongorora Mashandisirwo Enyaya

Mugadziri we semiconductor anozivikanwa aisangana nengura kakawanda uye kukwegura kwezvisimbiso zverabha zvechinyakare mumichina yekuchekerera pamutsetse wayo wekugadzira machipisi. Izvi zvakaita kuti pave nekubuda kwemvura mukati, zvichikanganisa kushanda zvakanaka kwekugadzira uye zvichideredza zvakanyanya goho remachipisi nekuda kwekusvibiswa kwezvikamu. Uyezve, zvisimbiso zvechinyakare zvakaburitsa tsvina yakawanda ye organic panguva yekupisa kwakanyanya, zvichisvibisa zvinhu zve semiconductor uye zvichikonzera kusagadzikana kwekushanda kwechigadzirwa. Mushure mekutsiva nezvisimbiso zve perfluoroelastomer zvakagadzirwa nekambani yedu, kugadzikana kwekushanda kwemuchina kwakavandudzika zvakanyanya. Mushure megore rekutarisa kushanda kwenguva dzose, zvisimbiso hazvina kuratidza ngura kana kukwegura, zvichichengetedza mukati makachena zvakanyanya, uye kuwedzera goho remachipisi kubva pa80% kusvika pamusoro pe95%. Izvi zvakawanikwa nekuda kwekusagona kwemakemikari kwe perfluoroelastomer seals, hunhu hwemvura shoma, uye hunhu hwakanaka hwemuviri, zvichikonzera mabhenefiti makuru ehupfumi kukambani.

Mhedziso: Muindasitiri yekugadzira zvinhu zve semiconductor, iyo inoedza kuve yakanyatsojeka uye yakachena, zvisimbiso zve rabha zvemhando yepamusoro zvine basa guru. Zvisimbiso zve rabha zvemhando yepamusoro zvakaita se fluoropolymer ne perfluoroelastomer, zvine mashandiro azvo epamusoro, kusanganisira kudzora mvura, zvinopa chisimbiso chakavimbika chemidziyo yekugadzira zvinhu zve semiconductor, zvichibatsira indasitiri iyi kuti irambe ichifambira mberi kusvika padanho repamusoro rehunyanzvi.

Nguva yekutumira: Gumiguru-17-2025