Tlhahisong ea indasteri le tlhahiso ea likoloi, theknoloji ea ho tiisa e bohlokoa ho netefatsa ts'ebetso e tšepahalang ea lisebelisoa. Haufinyane tjena, tiiso ea lihokelo tse peli e nang le moralo o mocha le ts'ebetso e ntle e kene 'marakeng, e fa indasteri tharollo e ncha ea ho tiisa le ho tsosa tlhokomelo e pharalletseng. Ka nako e ts'oanang, setšoantšo se qaqileng se bonts'ang enjene le likarolo tsa eona se arolelanoe haholo inthaneteng, se ntlafatsa kutloisiso ea batho ka sebopeho sa enjene le ts'ebeliso ea likarolo tsa ho tiisa.

1. Ponahalo ea Sehlahisoa le Thepa ea Thepa

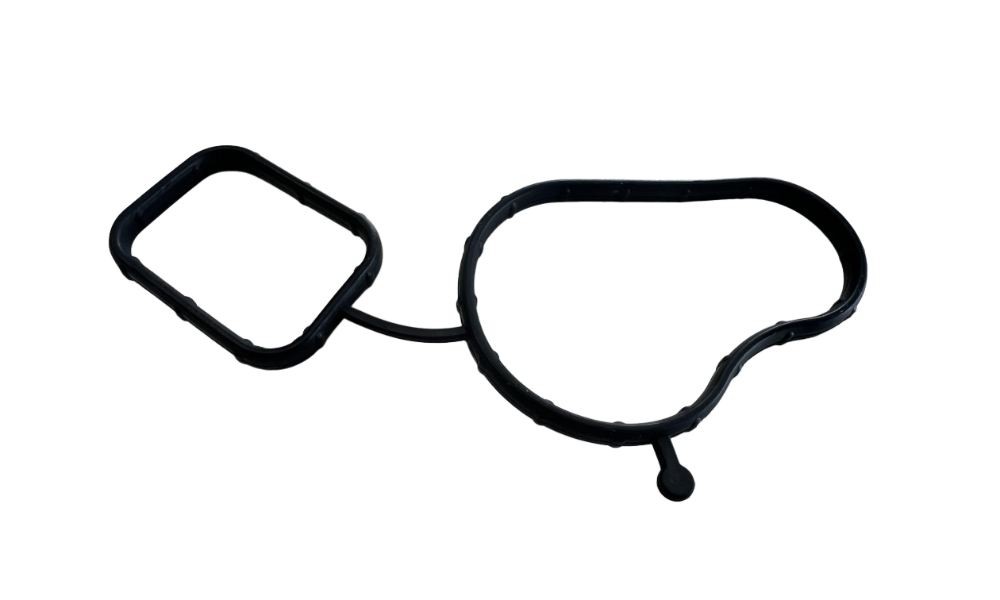

Setiiso sa kgokelo e habeli se na le masale a mabedi a rabara a hokahantsweng: lehlakore le leng ke lesale le sekwere, ha lehlakore le leng e le lesale le leholo la elliptical le nang le letheba le lenyenyane qetellong. Moralo ona ha o fihlelle feela boqapi ba sebopeho empa hape o nahana ka botlalo ka ditlhoko tsa tshebetso maemong a ho kenya le ho sebedisa a nnete. E entswe ka rabara ya boleng bo hodimo mme e sebetswa ka theknoloji e tswetseng pele ya ho ntsha dikokwana-hloko. Thepa ya rabara ka boyona e na le ho tenyetseha ho hoholo, ho hanyetsa ho tsofala, le ho hanyetsa ho bola. Ts'ebetso ya ho ntsha dikokwana-hloko e ntlafatsa sebopeho sa yona sa dimolek'hule, e netefatsa hore e boloka thepa ya mmele e tsitsitseng kahare ho mocheso wa -40°C ho isa ho 150°C le dibakeng tse nang le kgatello e phahameng, tse rarahaneng ka dikhemikhale, e thibela ka katleho botsofali, ho fetofetoha ha dikokwana-hloko le mathata a mang, e netefatsa tshebetso ya ho kwala nako e telele.

2. Mesebetsi ea Bohlokoa le Masimo a Ts'ebeliso

(a) Tshebetso e Ikhethang ea ho Tiisa

Lisebelisoang tsa mechini le tsa likoloi, ho dutla ha metsi ke ntlha ea bohlokoa e amang ts'ebetso e tloaelehileng. Ka lebaka la sebopeho sa eona se ikhethang le thepa ea rabara ea boleng bo holimo, tiiso ea khokahano e habeli e ka tlatsa likheo tse nyane lipakeng tsa likarolo, ea etsa mokoallo o tšepahalang oa ho tiisa. Mohlala, lienjineng tsa likoloi, gasket ea hlooho ea silindara ea hlokahala pakeng tsa hlooho ea silindara le boloko ba silindara ho thibela ho dutla ha oli e pholileng le enjene. Karolo ea selikalikoe sa tiiso ea khokahano e habeli e ka ikamahanya hantle le li-interface tse tšoanang, ea thibela ho dutla ha oli le pholileng le ho kopanya, ea netefatsa ts'ebetso e tsitsitseng ea enjene tlas'a mocheso o phahameng, khatello e phahameng le ho thothomela, ea boloka litlolo tse ntle le litlamorao tse pholileng, le ho lelefatsa bophelo ba enjene. Litsamaisong tsa hydraulic tsa lisebelisoa tsa mechini, karolo ea lesale la elliptical e lekana hantle likarolo tse hokahanyang tsa li-cylinder tsa hydraulic le lipompo, ea boloka ho koaloa tlas'a tšusumetso ea oli e phahameng ka lebaka la bokhoni ba eona bo botle ba ho feto-fetoha ha elastic, ea netefatsa ts'ebetso e sebetsang ea litsamaiso tsa hydraulic le ho ntlafatsa ts'ebetso ea mechini le ho nepahala ha ts'ebetso.

(b) Mosebetsi oa Khokahano le ho Lokisa

Sebopeho sa lesale le habeli sa tiiso ea khokahano e habeli se e fa mesebetsi ea ho tiisa le ea ho hokahanya. Ha ho kopanngoa likarolo tsa likoloi, joalo ka khokahano pakeng tsa intake manifold le block ea enjene, tiiso e kenngoa sebakeng sa ho hokahanya, eseng feela ho fana ka ho tiisa ho thibela ho lutla empa hape le ho ntlafatsa ho tiea ha khokahano ka ho fetoha ha elastic le likarolo tsa sebopeho, ho fokotsa kotsi ea ho hloleha ho bakoang ke ho hlepha. Litsamaisong tsa liphaephe tsa indasteri, e nolofatsa ts'ebetso ea khokahano ea phaephe, e nkela mekhoa ea setso e rarahaneng ea khokahano ea bolt le linate sebaka, e nolofalletsa ho tiisa le ho lokisa phaephe ka potlako, ho fokotsa likotsi tsa ho lutla, ho fokotsa litšenyehelo tsa tlhokomelo le ho rarahana, le ho ntlafatsa ts'ebetso ea ho tsamaisa thepa le polokeho.

3. Melemo ea Bohlokoa ea Tshebetso

(a) Ho Ikamahanya le Maemo a Mocheso o Batsi

Lisebelisoa tsa indasteri le mechine ea likoloi hangata li tobana le maemo a mocheso o feteletseng. Thepa ea rabara ea tiiso ea lihokelo tse peli e entsoe ka ho khetheha ho boloka ts'ebetso e tsitsitseng le katleho ea ho koala ka har'a mocheso oa -40°C ho isa ho 150°C. Mariheng a batang, e ka khutlisa ho tenyetseha ha eona kapele ho netefatsa ho tlotsa ho tloaelehileng ha lienjene tsa likoloi, ha libakeng tse nang le mocheso o phahameng, ha e nolofatse kapa ho senyehe, e sireletsa likarolo tsa ka hare le maro a tsona ka ho tsoelang pele.

(b) Ho Hanela ho Tshabala ho Hoholo le ho Hanela Botsofali

Ho tsamaiswa kgafetsa ha disebediswa le ditiiso tsa nako e telele tse sebediswang ke dikoloi ho ya kgohlanong e tswelang pele le kgatellong ya mechine. Setiiso sa dihokelo tse pedi se sebedisa thepa ya rabara ya boleng bo hodimo e nang le kalafo e ikgethang ya bokahodimo ho fokotsa kgohlano, e diehisang ho tsofala. Ho feta moo, di-additives tse thibelang botsofadi tse ekeditsweng setiisong di hanela ka katleho ditlamorao tsa mahlasedi a UV, ozone, le mabaka a mang a tikoloho. Esita le ka mora motsamao o rarahaneng wa mechine wa nako e telele, e boloka ho tenyetseha le tshebetso e ntle ya ho kwala, e fokotsa kgafetsa ya tlhokomelo le ho nkela sebaka ha disebediswa, e fokotsa ditjeo tsa tshebetso, mme e ntlafatsa bokgoni ba tlhahiso.

(c) Khanyetso e Pharaletseng ea Lik'hemik'hale

Tlhahisong ea indasteri le ts'ebetsong ea likoloi, litiiso li pepesetsoa lik'hemik'hale tse fapaneng. Thepa ea rabara ea setiiso sa lihokelo tse peli e etselitsoe ho ba le khanyetso e ntle ho maro a tloaelehileng a likoloi, oli ea hydraulic ea indasteri, litlolo le lintho tse ling. Ha e fetele liphetohong tse kholo tsa 'mele kapa tsa lik'hemik'hale esita le ka mor'a ho pepesehela nako e telele, e leng ho thibelang ho lutla ha mokelikeli le ho bola ha likarolo tsa lisebelisoa, ho netefatsa ts'ebetso e tsitsitseng ea lisebelisoa libakeng tse rarahaneng tsa lik'hemik'hale.

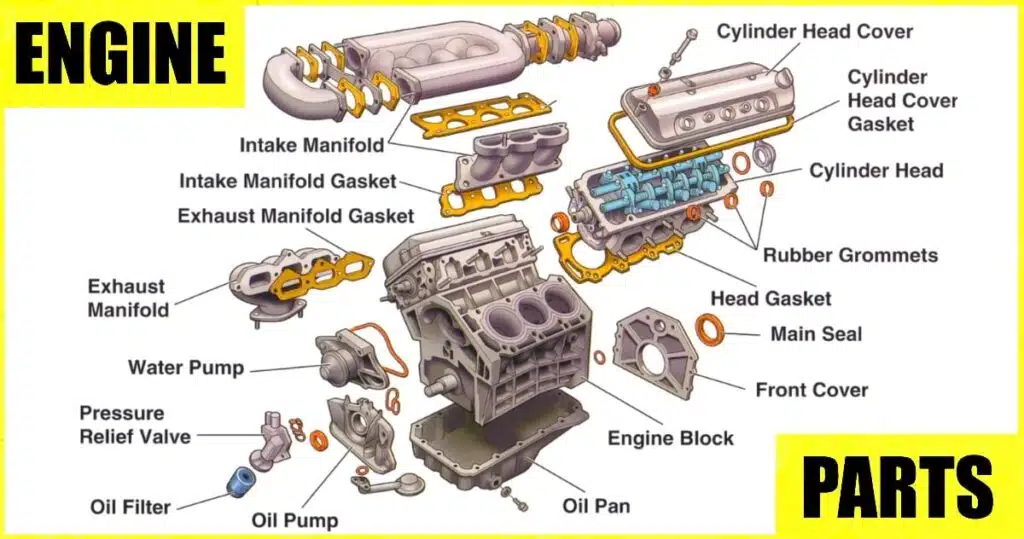

4. Boemo le Mosebetsi oa Litiiso tsa Sehokelo se Peli ka Lienjeneng

Ho tsoa setšoantšong, ho ka bonoa hore tiiso ea khokahano e habeli e kentsoe haholo-holo pakeng tsa manifold ea intake le block ea enjene, hammoho le pakeng tsa block ea silindara le hlooho ea silindara. Libakeng tsena tsa bohlokoa, tiiso ea khokahano e habeli e bapala karolo ea bohlokoa ho koaleng. Karolo ea lesale la sekwere e lekana hantle khokahanong pakeng tsa hlooho ea silindara le block ea silindara, e thibela ka katleho ho lutla ha oli ea enjene le coolant le ho netefatsa hore maro a ka hare ho enjene a boloka mesebetsi e tloaelehileng ea ho tlotsa le ho pholisa tlas'a mocheso o phahameng, khatello e phahameng le ho thothomela. Karolo ea lesale la elliptical e kentsoe pakeng tsa manifold ea intake le block ea silindara, e netefatsa ho koalloa ha ts'ebetso ea ho kenya e le hore moea kapa metsoako e tukang e ka kena silindara ka 'ngoe ka ho lekana le ka nepo, ka hona e netefatsa katleho ea ho chesa enjene le tlhahiso ea matla. Tlhahiso ena e bonolo ha e lumelle feela batho ba bangata ho fumana kutloisiso e tebileng ea tiiso ea khokahano e habeli empa hape e fana ka thepa ea bohlokoa ea litšupiso bakeng sa litsebi tsa indasteri, e khothalletsa phapanyetsano le boqapi ba mahlale a ho tiisa.

Nako ea poso: Mots'eanong-21-2025