PTFE e koahetsoeng ka O-Ring

Li-O-Rings tse koahetsoeng ka PTFE ke eng?

Masale a O a koahetsoeng ka PTFE ke litiiso tse kopantsoeng tse nang le motheo oa rabara oa O-ring oa setso (mohlala, NBR, FKM, EPDM, VMQ) e le substrate e tenyetsehang, eo holim'a eona ho sebelisoang filimi e tšesaane, e tšoanang, le e tlamiloeng ka thata ea polytetrafluoroethylene (PTFE). Sebopeho sena se kopanya melemo ea thepa ka bobeli, e leng se fellang ka litšobotsi tse ikhethang tsa ts'ebetso.

Libaka tsa Ts'ebeliso ea Motheo

Ka lebaka la thepa ea tsona e ikhethang, mehele ea O e koahetsoeng ka PTFE e sebelisoa haholo libakeng tse hlokang tlhokomelo e khethehileng tse nang le litlhoko tse khethehileng tsa ho tiisa:

Indasteri ea Lik'hemik'hale le Petrochemical:

Li-valve tsa ho koala, lipompo, li-reactor le li-flange tsa liphaephe tse sebetsanang le lintho tse senyang haholo joalo ka li-acid tse matla, li-alkali tse matla, li-oxidizer tse matla le li-solvent tsa tlhaho.

Ho kwala ka har'a litsamaiso tsa ho tlisa lik'hemik'hale tse hloekileng haholo ho thibela tšilafalo.

Indasteri ea Meriana le Biotechnology:

Ho kwala bakeng sa disebediswa tsa tshebetso ho hloka bohloeki bo phahameng, ha ho na leaching, mme ha ho na tšilafalo (mohlala, di-bioreactor, di-fermenter, ditsamaiso tsa tlhoekiso, mela ya ho tlatsa).

Ho kwala ho hanela dihlatswa tse matla tsa dikhemikhale le mouoane o mocheso o phahameng o sebediswang ditshebetsong tsa CIP (Clean-in-Place) le SIP (Sterilize-in-Place).

Indasteri ea Lijo le Lino:

Litiiso tsa lisebelisoa tse fihlelang melao ea FDA/USDA/EU ea ho kopana le lijo (mohlala, lisebelisoa tsa ts'ebetso, li-filler, liphaephe).

E hanela li-cleanser le li-sanitizer tsa maemo a holimo lijong.

Indasteri ea Semiconductor le Elektroniki:

Litiiso bakeng sa litsamaiso tsa ho tsamaisa le ho sebetsana le metsi a hloekileng haholo (UPW) le lik'hemik'hale tse hloekileng haholo (li-acid, li-alkali, li-solvents), tse hlokang tlhahiso e tlase haholo ea likaroloana le leaching ea li-ion tsa tšepe.

Litiiso tsa likamore tsa vacuum le lisebelisoa tsa ho sebetsana le plasma (tse hlokang khase e fokolang).

Indasteri ea Likoloi:

Ho kwala dibakeng tse nang le mocheso o phahameng jwalo ka ditsamaiso tsa turbocharger le ditsamaiso tsa EGR.

Litiiso tse hlokang khohlano e tlase le khanyetso ea lik'hemik'hale litsamaisong tsa phetiso le tsa mafura.

Lisebelisoa lits'ebetsong tse ncha tsa ho pholisa libeteri tsa likoloi tsa motlakase.

Lifofane le Tšireletso:

Litiiso tse hlokang ho tšepahala ho hoholo, ho hanyetsa mocheso o feteletseng, le ho hanyetsa mafura a khethehileng/metsi a metsi tsamaisong ea hydraulic, litsamaisong tsa mafura le litsamaisong tsa taolo ea tikoloho.

Indasteri e Akaretsang:

Litiiso bakeng sa lisilindara tsa pneumatic le hydraulic tse hlokang khohlano e tlase, bophelo bo bolelele, le ho hanyetsa ho tsofala (haholo-holo bakeng sa motsamao o potlakileng le o phahameng oa ho pheta-pheta).

Litiiso bakeng sa li-valve tse fapaneng, lipompo le lihokelo tse hlokang khanyetso ea lik'hemik'hale le litšobotsi tse sa khomareleng.

Litiiso tsa lisebelisoa tsa vacuum (tse hlokang hore peterole e se ke ea tsoa ka khase e ngata).

Melemo e Ikhethang le Litšobotsi tsa Tshebetso

Molemo oa mantlha oa mehele ea O e koahetsoeng ka PTFE o holim'a ts'ebetso e ntlafalitsoeng ea motsoako o tsoang sebopehong sa ona:

Ho se sebetse hantle ha lik'hemik'hale:

E 'ngoe ea melemo ea mantlha. PTFE e bontša khanyetso e ikhethang ho hoo e batlang e le lik'hemik'hale tsohle (ho kenyeletsoa le li-acid tse matla, li-alkali tse matla, aqua regia, li-solvents tsa organic, jj.), tseo li-substrate tse ngata tsa rabara li ke keng tsa li finyella li le mong. Seaparo sena se arola ka katleho mecha ea litaba e senyang ho tloha bohareng ba rabara bo ka hare, se atolosa haholo mefuta ea ts'ebeliso ea O-ring libakeng tse feteletseng tsa lik'hemik'hale.

Koefficient e Tlase Haholo ea Khohlano (CoF):

Molemo oa bohlokoa. PTFE e na le e 'ngoe ea boleng bo tlase ka ho fetisisa ba CoF har'a thepa e tiileng e tsejoang (hangata 0.05-0.1). Sena se etsa hore mehele ea O e koahetsoeng e be ntle haholo lits'ebetsong tsa ho tiisa ka matla (mohlala, lithupa tsa piston tse khutlisetsang, li-shaft tse potolohang):

E fokotsa haholo ho phatloha le ho qabana ha ho sebetsa.

E fokotsa mocheso le ho tsofala ho bakoang ke khohlano.

E atolosa bophelo ba tiiso (haholo-holo lits'ebetsong tsa lebelo le phahameng, tse sebelisoang khafetsa).

E ntlafatsa ts'ebetso ea matla ea sistimi.

Mefuta e Meholo ea Mocheso o Sebetsang:

Seaparo sa PTFE ka bosona se boloka tshebetso ho pholletsa le mocheso o pharaletseng haholo ho tloha ho -200°C ho isa ho +260°C (nako e kgutshwane ho fihlela ho +300°C). Sena se atolosa haholo moedi o ka hodimo wa mocheso wa rabara ya motheo ya O-ring (mohlala, motheo wa NBR hangata o lekanyeditswe ho ~120°C, empa ka seaparo sa PTFE se ka sebediswa maemong a lehodimo a hodimo, ho itshetlehile ka rabara e kgethilweng). Tshebetso ya mocheso o tlase le yona e a netefatswa.

Matlotlo a Hloahloa a sa Khomareleng le a sa Koaheleng:

PTFE e na le matla a tlase haholo a bokaholimo, e leng se etsang hore e hanele ho khomarela le ho se kolobisoe ke metsi le metsi a thehiloeng oling. Sena se fella ka:

Ho fokotseha ha litšila, ho koaheloa, kapa ho khomarela masala a mecha ea phatlalatso holim'a libaka tse koalang.

Ho hlwekisa ho bonolo, haholo-holo ho loketse mafapha a bohloeki bo phahameng joalo ka lijo le meriana.

Ho boloka ts'ebetso ea ho tiisa esita le ka mecha ea phatlalatso e hlabang.

Bohloeki bo Phahameng le Lintho tse sa Luleng ho Lutla:

Bokaholimo bo boreleli, bo teteaneng ba PTFE bo fokotsa ho dutla ha dikarolwana, di-additives, kapa dintho tse boima bo tlase ba dimolek'hule. Sena se bohlokwa bakeng sa tshebediso ya bohloeki bo phahameng haholo ho di-semiconductors, dikhemistri, di-biotech, le dijo le dino, e leng se thibelang tshilafatso ya sehlahiswa ka katleho.

Khanyetso e Ntle ea ho Tloha:

Leha ho hanyetsa ho robeha ha PTFE ka tlhaho ho sa loka, CoF ea eona e tlase haholo e fokotsa sekhahla sa ho robeha haholo. Ha e kopantsoe le substrate e loketseng ea rabara (e fanang ka tšehetso le mamello) le qetello e loketseng ea bokaholimo/ho tlotsa, mehele ea O e koahetsoeng ka kakaretso e bontša ho hanyetsa ho robeha ho betere ho feta mehele ea O ea rabara e se nang letho lits'ebetsong tse matla.

Khanyetso e Ntlafalitsoeng ea Lik'hemik'hale tsa Substrate ea Rubber:

Sekoahelo se sireletsa karolo e ka hare ea rabara tlhaselong ea mecha ea phatlalatso, se lumella tšebeliso ea thepa ea rabara e nang le thepa e betere ea tlhaho (joalo ka ho tenyetseha kapa litšenyehelo, mohlala, NBR) mecheng ea phatlalatso eo hangata e neng e tla ruruha, e thatafatse, kapa e senye rabara. E "sireletsa" ho tenyetseha ha rabara ka ho hanyetsa lik'hemik'hale tsa PTFE.

Ho lumellana hantle ha Vacuum:

Liaparo tsa PTFE tsa boleng bo holimo li na le botenya bo botle le ho tsoa ha khase ka tlhaho ho tlase, hammoho le ho tenyetseha ha karolo ea mantlha ea rabara, e fanang ka ho koala ha vacuum ka katleho.

3. Lintho tsa Bohlokoa tseo u lokelang ho li ela hloko

Theko: E phahame ho feta mehele ea rabara e tloaelehileng.

Litlhoko tsa ho Kenya: Ho hlokahala hore ho sebetsanoe ka hloko ho qoba ho senya seaparo ka lisebelisoa tse bohale. Li-groove tsa ho kenya li lokela ho ba le li-chamfer tse lekaneng tsa lead-in le lipheletso tse boreleli tsa bokaholimo.

Botšepehi ba ho Koahela: Boleng ba ho koahela (ho khomarela, ho tšoana, ho se be le masoba a pin) bo bohlokoa haholo. Haeba ho koahela ho senyehile, rabara e pepeneneng e lahleheloa ke khanyetso ea eona e matla ea lik'hemik'hale.

Sete ea Khatello: Haholo-holo e itšetlehile ka substrate ea rabara e khethiloeng. Seaparo ka bosona ha se fane ka matla a ho hatelloa.

Bophelo ba Tšebeletso e Matla: Le hoja e le betere haholo ho feta rabara e se nang letho, lesela le tla qetella le felile ka lebaka la motsamao o molelele, o matla oa ho pheta-pheta kapa oa ho potoloha. Ho khetha rabara tsa motheo tse sa tsofaleng (mohlala, FKM) le moralo o ntlafalitsoeng ho ka lelefatsa bophelo.

Kakaretso

Boleng ba mantlha ba mehele ea O e koahetsoeng ka PTFE bo itšetlehile ka hore na sekoahelo sa PTFE se fana ka ho se sebetse hantle ha lik'hemik'hale joang, coefficient e tlase haholo ea khohlano, mefuta e mengata ea mocheso, thepa e sa khomareleng, bohloeki bo phahameng le tšireletso ea substrate ho mehele ea O ea rabara ea setso. Ke tharollo e ntle bakeng sa liphephetso tse hlokang ho koaloa tse kenyeletsang mafome a matla, bohloeki bo phahameng, khohlano e tlase, le mefuta e mengata ea mocheso. Ha u khetha, ho bohlokoa ho khetha thepa e loketseng ea substrate ea rabara le litlhaloso tsa ho koahela ho latela ts'ebeliso e itseng (mecha ea phatlalatso, mocheso, khatello, matla/e sa fetoheng), le ho netefatsa ho kenngoa le tlhokomelo e nepahetseng ho boloka botšepehi ba ho koahela le ts'ebetso ea ho koala.

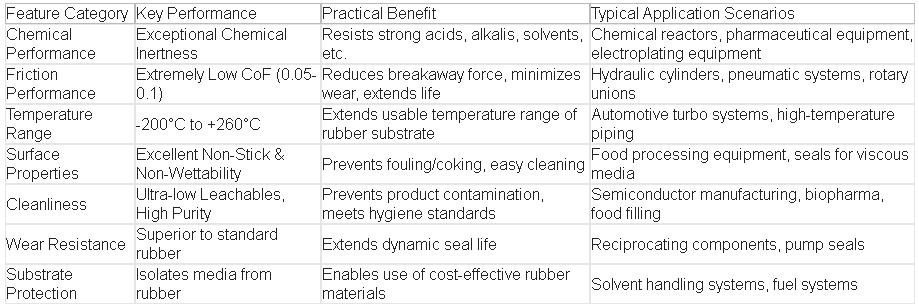

Tafole e ka tlase e akaretsa litšobotsi tsa bohlokoa le ts'ebeliso ea mehele ea O e koahetsoeng ka PTFE: