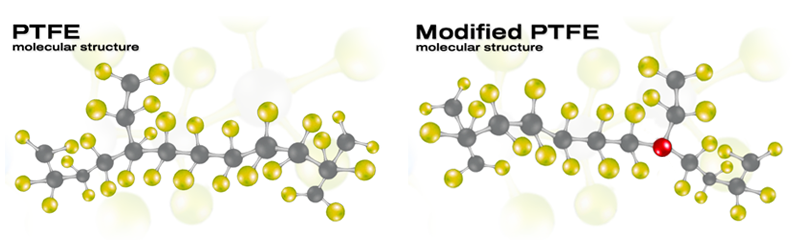

I-Polytetrafluoroethylene (PTFE), eyaziwa ngokuba "ngukumkani weplastiki," inika ukumelana okungaqhelekanga kweekhemikhali, i-coefficient ephantsi yokungqubana, kunye nozinzo kubushushu obuphezulu. Nangona kunjalo, imida yayo yendalo—njengokumelana nokuguguleka okungekuhle, ubulukhuni obuphantsi, kunye nokuthambekela ekunyukeni—kuye kwakhokelela ekuphuhlisweni kwe-filledIi-PTFE compositesNgokufaka izizalisi ezifana nefayibha yeglasi, ifayibha yekhabhoni, kunye negrafiti, abavelisi banokwenza iipropati zePTFE zilungele ukusetyenziswa okufunekayo kwi-aerospace, iimoto, kunye nokutywinwa kwemizi-mveliso. Eli nqaku lihlola indlela ezi zizalisi eziphucula ngayo iPTFE kwaye libonelela ngesikhokelo sokukhetha i-composite efanelekileyo ngokusekelwe kwiimfuno zokusebenza.

1. Isidingo sokuguqulwa kwe-PTFE

I-PTFE ecocekileyo igqwesile ekumelaneni nokugqwala kunye nokungqubana okuncinci kodwa ineengxaki zoomatshini. Umzekelo, ukumelana kwayo nokuguguleka akwanelanga ukusetyenziswa kokutywina okunamandla, kwaye iyaguquguquka phantsi koxinzelelo oluqhubekayo (ukuhamba okubandayo). Izizalisi zijongana nale micimbi ngokusebenza njengee-skeletons eziqinisayo kwi-PTFE matrix, ukuphucula ukumelana nokuqhekeka, ukunyamezela ukuguguleka, kunye nokuqhuba ubushushu ngaphandle kokubeka emngciphekweni izibonelelo zayo eziphambili.

2. I-Glass Fiber: Isiqinisekisi Esisebenza Ngexabiso Eliphantsi

Iipropati eziphambili

Ukumelana nokunxitywa: Ifayibha yeglasi (GF) inciphisa izinga lokunxitywa kwePTFE ukuya kuthi ga kumaxesha angama-500, nto leyo eyenza ukuba ifaneleke kwiindawo ezinomthwalo omninzi.

Ukunciphisa ukuqhekeka: I-GF iphucula uzinzo lobukhulu, inciphisa ukuguquguquka phantsi koxinzelelo oluqhubekayo.

Imida yoBushushu kunye neeKhemikhali: I-GF isebenza kakuhle kumaqondo obushushu afikelela kwi-400°C kodwa yonakala kwi-hydrofluoric acid okanye kwiziseko eziqinileyo.

Izicelo

I-PTFE eqiniswe yi-GF isetyenziswa kakhulu kwiiseal ze-hydraulic, ii-cylinders ze-pneumatic, kunye nee-gaskets zoshishino apho amandla oomatshini kunye nokusebenza kakuhle kweendleko kubekwa phambili. Ukuhambelana kwayo nezinye izongezo ezifana ne-MoS₂ kuphucula ngakumbi ulawulo lokungqubana.

3. I-Carbon Fiber: Ukhetho Lokusebenza Okuphezulu

Iipropati eziphambili

Amandla nokuqina: I-Carbon fiber (CF) inika amandla okutsalwa kunye ne-flexural modulus ephezulu, ifuna i-filler volumes ephantsi kune-GF ukuze kufezekiswe ukuqina okufanayo.

Ukuqhuba Ubushushu: I-CF iphucula ukusasazwa kobushushu, nto leyo ibalulekileyo kwizicelo ezikhawulezayo.

Ukungangeni kweekhemikhali: I-CF iyamelana nee-asidi ezinamandla (ngaphandle kwee-oxidizers) kwaye ifanelekile kwiindawo ezinobungozi zeekhemikhali.

Izicelo

Ii-CF-PTFE composites zibalasele kwi-automotive shock absorbers, kwizixhobo ze-semiconductor, nakwizinto ze-aerospace, apho ukuqina okukhaphukhaphu kunye nolawulo lobushushu kubalulekile.

4. I-Graphite: Ingcali yokuthambisa

Iipropati eziphambili

Ukungqubana okuphantsi: I-PTFE egcwele iGraphite ifikelela kwii-coefficients zokungqubana eziphantsi njenge-0.02, nto leyo enciphisa ukulahleka kwamandla kwiinkqubo eziguqukayo.

Uzinzo lobushushu: I-Graphite iphucula ukuhanjiswa kobushushu, ithintela ukuqokelelana kobushushu kwiindawo ezifikelela kwisantya esiphezulu.

Ukuhambelana Kokudibana Okuthambileyo: Kunciphisa ukuguguleka kwiindawo ezithambileyo ezifana ne-aluminium okanye ubhedu.

Izicelo

Ii-composites ezisekelwe kwi-graphite zikhethwa kakhulu kwiibheringi ezingathanjiswenga, kwii-compressor seals, nakwiimashini ezijikelezayo apho ukusebenza kakuhle kunye nokuchithwa kobushushu kubaluleke kakhulu.

5. Isishwankathelo sokuthelekisa: Ukukhetha i-Filler echanekileyo

| Uhlobo lokugcwalisa | Ukumelana nokunxitywa | I-Friction Coefficient | Ukuqhuba kweThermal | Eyona ilungileyo |

| Ifayibha yeglasi | Phezulu (uphuculo oluphindwe ka-500) | Iphakathi | Iphakathi | Iitywina ezizinzileyo/ezitshintshayo ezinobunzima obuphezulu, ezinomthwalo ophezulu |

| I-Carbon Fiber | Phezulu kakhulu | Iphantsi ukuya kwephakathi | Phezulu | Iindawo ezikhaphukhaphu, ezinobushushu obuphezulu, nezirhabaxa |

| I-Graphite | Iphakathi | Iphantsi kakhulu (0.02) | Phezulu | Izicelo ezingatyiswanga, ezisebenza ngesantya esiphezulu |

Iindidi eziHlanganisiweyo

Ukudibanisa izizalisi—umz., ifayibha yeglasi eneMoS₂ okanye ifayibha yekhabhoni enegrafiti—kunokuphucula iipropati ezininzi. Umzekelo, ii-hybrids zeGF-MoS₂ zinciphisa ukungqubana ngelixa zigcina ukumelana nokuguguleka.

6. Iziphumo kwiShishini kunye noZinzo

Ii-PTFE composites ezizalisiweyo zandisa ubomi bezinto, zinciphisa amaxesha okugcinwa kwazo, kwaye zonyusa ukusebenza kakuhle kwamandla. Umzekelo, ii-graphite-PTFE seals kwiinkqubo ze-LNG zimelana namaqondo obushushu ukusuka kwi--180°C ukuya kwi-+250°C, ziphumelela ngaphezu kwezinto eziqhelekileyo. Ezi nkqubela phambili zihambelana neenjongo zoqoqosho olujikelezayo ngokunciphisa inkunkuma ngoyilo oluhlala ixesha elide.

Isiphelo

Ukukhethwa kwe-filler—i-glass fiber, i-carbon fiber, okanye i-graphite—kulawula ukusebenza kwe-PTFE composites. Ngelixa i-glass fiber inika ixabiso elilinganayo kunye nokuqina, i-carbon fiber igqwesa kwiimeko eziqatha, kwaye i-graphite ibeka phambili ukuthambisa. Ukuqonda la mahluko kwenza iinjineli zilungelelanise izisombululo zokutywina ukuze zithembeke kwaye zisebenze kakuhle.

Njengoko amashishini etshintsha ukuya kwimigangatho ephezulu yokusebenza, ukusebenzisana neengcali kwisayensi yezinto ezibonakalayo kuqinisekisa uphuhliso olufanelekileyo lwemveliso. I-Ningbo Yokey Precision Technology isebenzisa ubuchule obuphezulu bokudibanisa ukuze inike izitywino ezihlangabezana neemfuno ezingqongqo zezicelo zeemoto, zamandla, nezemizi-mveliso.

Amagama angundoqo: ii-PTFE composites, izisombululo zokutywina, ubunjineli bezinto, izicelo zoshishino

Iireferensi

Iindlela zokuguqula izinto ze-PTFE (2017).

Izixhobo ze-PTFE ezidityanisiweyo – iMicflon (2023).

Iziphumo zokuzalisa kwiZakhiwo zePTFE – I-Global Tribune (2021).

Ukusebenza kweGasket yePTFE eguquliweyo (2025).

Uphuhliso oluPhambili lweFluoropolymer (2023).

Ixesha lokuthumela: Jan-09-2026