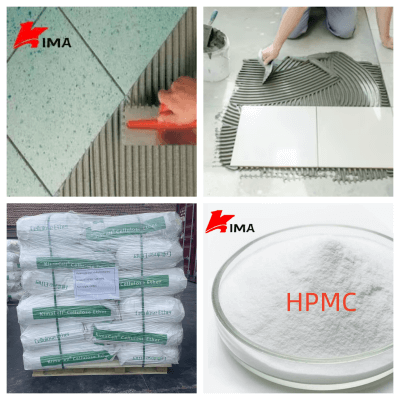

IHydroxypropyl Methylcellulose (HPMC)yi-non-ionic cellulose ether esetyenziswa kakhulu kwizixhobo zokwakha, ingakumbi kwi-tile adhesives. I-HPMC ibe sisongezelelo esibalulekileyo kwimihombiso yezakhiwo zanamhlanje ngokuphucula ukusebenza kolwakhiwo, ukugcinwa kwamanzi, kunye namandla okubopha kwe-tile adhesives.

1. Phucula ukusebenza kolwakhiwo

1.1. Phucula ukusebenza kakuhle

I-HPMC ine-lubrication kunye ne-adhesive elungileyo. Ukuyifaka kwi-adhesive yethayile kunokuphucula kakhulu ukusebenza kakuhle kwe-mortar, kwenze kube lula ukuyikrwela nokuguda, kwaye kuphucule ukusebenza kakuhle kunye nomgangatho wokwakha wabasebenzi bokwakha.

1.2. Thintela ukugoba

Xa i-adhesive yethayile isetyenziswa kumphezulu othe nkqo, kulula ukugoba ngenxa yobunzima bayo. I-HPMC iphucula ngempumelelo i-adhesive engagugiyo ngokusebenzisa ii-adhesive zayo eziqinileyo kunye ne-thixotropic, ukuze iithayile zikwazi ukugcina indawo ezinzileyo emva kokugawulwa kunye nokuthintela ukutyibilika.

2. Ukuphucula ukugcinwa kwamanzi

2.1. Nciphisa ukulahleka kwamanzi

I-HPMC inokusebenza kakuhle kokugcina amanzi. Inganciphisa kakhulu ukufuma kwamanzi ngokukhawuleza okanye ukufunxwa lulwahlulo olusisiseko kwi-adhesive yethayile, yandise ixesha elivulekileyo kunye nexesha lokulungisa i-adhesive, kwaye inike abasebenzi bokwakha ukuguquguquka okukhulu kokusebenza.

2.2. Khuthaza impendulo yokufunxwa kwesamente

Ukugcinwa kakuhle kwamanzi kunceda isamente ukuba ifume ngokupheleleyo kwaye yenze iimveliso zokufuma ngakumbi, ngaloo ndlela yonyusa amandla okubopha kunye nokuqina kweglue yethayile.

3. Phucula amandla okubopha kunye namandla

3.1. Phucula ulwakhiwo lwe-bonding interface

I-HPMC yenza isakhiwo senethiwekhi yepolymer esincinci kwi-adhesive, ephucula ukusebenza kwe-bonding phakathi kwe-adhesive yethayile kunye neethayile kunye nomaleko wesiseko. Nokuba ziithayile ezifunxayo okanye iithayile ezifunxayo amanzi kancinci (ezifana neethayile ezi-vitrified kunye neethayile ezipholisiweyo), i-HPMC inokubonelela ngamandla e-bonding azinzileyo.

3.2. Yomeleza ukumelana nokuqhekeka kunye nokuguquguquka

Ulwakhiwo lwepolymer lwe-HPMC lwenza ukuba i-tile adhesive ibe nokuguquguquka okuthile, okunokulungela ukuguquguquka okuncinci okanye ukwanda kobushushu kunye nokucutheka komaleko wesiseko, kwaye kunciphise iingxaki zomgangatho ezifana nokuqhekeka kunye nokuqhekeka okubangelwa kukuxinana koxinzelelo.

4. Phucula ukulungelelaniswa kolwakhiwo

4.1. Ziqhelanise neemeko ezahlukeneyo zokwakha

Phantsi kweemeko zemozulu ezimbi ezifana nobushushu obuphezulu, ukoma okanye umoya onamandla, izincamathelisi zethayile eziqhelekileyo zidla ngokoma ngokukhawuleza kakhulu, nto leyo ebangela ukungasebenzi kakuhle kwe-bonding. I-HPMC inokulibazisa ukulahleka kwamanzi ngenxa yokugcina kwayo amanzi kakuhle kunye neempawu zokwenza ifilimu, nto leyo eyenza izincamathelisi zethayile zilungele ukwakhiwa okuqhelekileyo kwiindawo ezahlukeneyo.

4.2. Isebenza kwiintlobo ngeentlobo ze-substrates

Nokuba yi-samente mortar leveling layer, i-concrete slab, i-tile surface endala okanye i-gypsum substrate, ii-tile adhesives ezongeziweyo ze-HPMC zinokubonelela ngokusebenza okuthembekileyo kwe-bonding, zandise uluhlu lwazo lokusetyenziswa.

5. Ukhuseleko nokusingqongileyo

I-HPMC yinto eluhlaza nenobuhlobo nokusingqongileyo engenabungozi, engenavumba, engatshiyo, kwaye ayizukubangela monakalo kwindalo okanye kwimpilo yabantu. Ayikhuphi izinto eziyingozi ngexesha lokwakhiwa, nto leyo ehambelana nombono wophuhliso lwezakhiwo zanamhlanje eziluhlaza.

6. Ukusebenza kakuhle ngokwezoqoqosho nangokwexesha elide

Nangona ixabiso le-HPMC liphezulu kancinci kunelo lezongezo zemveli, liphucula kakhulu ukusebenza kwezincamathelisi zethayile, linciphisa izinga lokuphinda lisetyenziswe kunye nenkunkuma yezinto, kwaye linezibonelelo eziphezulu kakhulu kwezoqoqosho ekuhambeni kwexesha. Izincamathelisi zethayile ezisemgangathweni ophezulu zithetha ukuba azinakugcinwa ixesha elide, zisebenza ixesha elide kwaye ziphucula neziphumo zokwakha.

7. Ukusebenzisana nezinye izongezo

I-HPMC ingasetyenziswa kunye nezinye izinto ezahlukeneyo, ezifanaIipowder zePolymer eziphinda zichithwe(RDP), i-starch ether, i-arhente yokugcina amanzi, njl.njl., ukuze kuphuculwe ngakumbi ukusebenza kwezincamathelisi zethayile. Umzekelo, xa isetyenziswa ne-RDP, inokuphucula ngaxeshanye ukuguquguquka kunye namandla okubopha; xa isetyenziswa ne-starch ether, inokuphucula ngakumbi ukugcinwa kwamanzi kunye nokuguda kolwakhiwo.

I-HPMC idlala indima ebalulekileyo kwizincamathelisi zethayile kwiinkalo ezininziIingenelo zayo eziphambili ziquka ukuphucula ukusebenza kolwakhiwo, ukuphucula ukugcinwa kwamanzi, ukuphucula ukunamathela, ukuphucula amandla okulwa nokugoba, kunye nokuziqhelanisa neentlobo ngeentlobo zeziseko kunye neendawo ezingqongileyo. Njengesongezelelo esibalulekileyo sokwakhiwa kwethayile zanamhlanje, i-HPMC ayihlangabezani nje neemfuno ezahlukeneyo zokwakha okwangoku, kodwa ikwakhuthaza inkqubela phambili yetekhnoloji kunye nophuhliso oluluhlaza kwishishini lokuncamathelisa iithayile.

Ixesha leposi: Juni-24-2025