I-O-Ring egqunywe yi-PTFE

Yintoni ii-O-Rings ezigqunywe yi-PTFE

Ii-O-rings ezigqunywe yi-PTFE zii-seal ezidityanisiweyo ezine-core yerabha ye-O-ring yendabuko (umz., i-NBR, i-FKM, i-EPDM, i-VMQ) njenge-substrate elastiki, apho kufakwa khona ifilimu encinci, efanayo, nebotshelelwe ngokuqinileyo ye-polytetrafluoroethylene (PTFE). Olu lwakhiwo ludibanisa iingenelo zezinto zombini, nto leyo ekhokelela kwiimpawu zokusebenza ezizodwa.

Iindawo eziPhambili zoSetyenziso

Ngenxa yeempawu zazo ezibalaseleyo, ii-O-rings ezine-PTFE ezigqunywe yi-O zisetyenziswa kakhulu kwiindawo ezifuna kakhulu ezineemfuno ezikhethekileyo zokutywina:

Ushishino lweeKhemikhali kunye neePetrochemical:

Iivalvu zokutywina, iimpompo, iireactors, kunye neeflanges zepayipi eziphatha izinto ezibangela ukonakaliswa okukhulu njengee-asidi ezinamandla, ii-alkalis ezinamandla, ii-oxidizers ezinamandla, kunye nezinyibilikisi zendalo.

Ukuvala kwiinkqubo zokuhambisa iikhemikhali ezicocekileyo kakhulu ukuthintela ungcoliseko.

Ushishino lweMithi kunye neBiotechnology:

Ukutywina izixhobo zenkqubo ezifuna ucoceko oluphezulu, akukho manzi aphumayo, kwaye akukho ngcoliseko (umz., ii-bioreactors, ii-fermenters, iinkqubo zokucoca, imigca yokuzalisa).

Ukutywina okumelana nezicoci zeekhemikhali eziqinileyo kunye nomphunga oshushu kakhulu osetyenziswa kwiinkqubo ze-CIP (Clean-in-Place) kunye ne-SIP (Sterilize-in-Place).

Ishishini lokutya neziselo:

Izitywino zezixhobo ezihlangabezana nemigaqo yoqhagamshelwano lokutya ye-FDA/USDA/EU (umz., izixhobo zokucubungula, izizalisi, imibhobho).

Ayinazo izixhobo zokucoca kunye nezicoci ezikumgangatho wokutya.

Ishishini leSemiconductor kunye ne-Electronics:

Iiseal zamanzi acocekileyo kakhulu (i-UPW) kunye neenkqubo zokuhambisa nokuphatha iikhemikhali ezicocekileyo kakhulu (ii-asidi, ii-alkali, izinyibilikisi), ezifuna ukuveliswa kwamasuntswana aphantsi kakhulu kunye nokutsalwa kwee-ion zesinyithi.

Izitywino zamagumbi okucoca i-vacuum kunye nezixhobo zokucubungula i-plasma (ezifuna ukukhupha igesi kancinci).

Ishishini leeMoto:

Ukuvala kwiindawo ezinobushushu obuphezulu ezifana neenkqubo ze-turbocharger kunye neenkqubo ze-EGR.

Izitywino ezifuna ukungqubana okuphantsi kunye nokumelana neekhemikhali kwiinkqubo zothumelo kunye nepetroli.

Usetyenziso kwiinkqubo zokupholisa iibhetri zezithuthi zamandla ezintsha.

Inqwelo-moya kunye noKhuselo:

Izitywini ezifuna ukuthembeka okuphezulu, ukumelana nobushushu obugqithisileyo, kunye nokuxhathisa amafutha akhethekileyo/ulwelo lwe-hydraulic kwiinkqubo ze-hydraulic, iinkqubo ze-fuel, kunye neenkqubo zolawulo lokusingqongileyo.

Ishishini Jikelele:

Izitywino zeesilinda ze-pneumatic neze-hydraulic ezifuna ukungqubana okuphantsi, ubomi obude, kunye nokumelana nokuguguleka (ingakumbi kwintshukumo ephindaphindayo ekhawulezayo nekhawulezayo).

Izitywino zeevalvu ezahlukeneyo, iimpompo, kunye nezihlanganisi ezifuna ukumelana neekhemikhali kunye neempawu ezinganamatheliyo.

Izitywino zezixhobo zokucoca umoya (ezifuna ukuba igesi ingabi namandla kakhulu).

Iingenelo ezizodwa kunye neempawu zokusebenza

Inzuzo ephambili yee-O-rings ezigqunywe yi-PTFE ikwindlela esebenza ngayo i-composite ephuculweyo evela kwisakhiwo sazo:

Ukungasebenzi kakuhle kweekhemikhali:

Enye yeenzuzo eziphambili. I-PTFE ibonakalisa ukumelana okubalaseleyo phantse kuzo zonke iikhemikhali (kuquka ii-asidi ezinamandla, ii-alkali ezinamandla, i-aqua regia, izinyibilikisi zendalo, njl.njl.), ezingenakufezwa zininzi ii-substrates zerabha zodwa. Ingubo iyawahlula ngokufanelekileyo amajelo arhabaxa kwi-inner rubber core, yandisa kakhulu uluhlu lwe-O-ring's application kwiindawo ezinobungozi kakhulu zeekhemikhali.

I-Coefficient of Friction ephantsi kakhulu (CoF):

Inzuzo ebalulekileyo. I-PTFE inexabiso eliphantsi le-CoF phakathi kwezinto eziqinileyo ezaziwayo (ngesiqhelo yi-0.05-0.1). Oku kwenza ii-O-rings ezigqunywe nge-coated zibe ngcono kwizicelo zokutywina eziguquguqukayo (umz., ii-piston rods ezijikelezayo, ii-shafts ezijikelezayo):

Kunciphisa kakhulu ukuqhekeka kunye nokungqubana okubalekayo.

Inciphisa ubushushu kunye nokuguguleka okubangelwa kukungqubana.

Yandisa ubomi besitywino (ingakumbi kwizicelo ezisebenzisa isantya esiphezulu neziphindaphindayo).

Iphucula ukusebenza kakuhle kwamandla enkqubo.

Uluhlu Olubanzi Lobushushu Bokusebenza:

Ingubo yePTFE ngokwayo igcina ukusebenza kuluhlu olubanzi kakhulu lobushushu ukusuka kwi -200°C ukuya kwi +260°C (ixesha elifutshane ukuya kuthi ga kwi +300°C). Oku kwandisa kakhulu umda wobushushu ophezulu we-O-ring yerabha esisiseko (umz., isiseko seNBR sihlala silinganiselwe kwi ~120°C, kodwa ngengubo yePTFE ingasetyenziswa kubushushu obuphezulu, kuxhomekeke kwirabha ekhethiweyo). Ukusebenza kobushushu obuphantsi nako kuyaqinisekiswa.

Iimpawu Ezintle Zokunganamatheli Nokungamanzi:

I-PTFE inamandla aphantsi kakhulu kumphezulu, nto leyo eyenza ukuba imelane kakhulu nokunamathela kwaye ingamanziswa ngamanzi kunye nolwelo olusekwe kwioyile. Oku kuphumela koku:

Ukunciphisa ukungcoliswa, ukucolwa, okanye ukunamathela kweentsalela zemidiya kwiindawo zokuvala.

Ukucoca kulula, okufanelekileyo ngakumbi kwiindawo ezicocekileyo ezifana nokutya kunye namayeza.

Ukusebenza kokutywina okugcinweyo nokuba usebenzisa izixhobo ezixineneyo.

Ukucoceka Okuphezulu kunye nokungangeni kwamanzi okuphantsi:

Umphezulu we-PTFE ogudileyo noxineneyo unciphisa ukuvuza kwamasuntswana, izongezo, okanye izinto ezinobunzima obuphantsi beemolekyuli. Oku kubalulekile kwizicelo zobunyulu obuphezulu kakhulu kwii-semiconductors, ii-pharma, ii-biotech, kunye nokutya neziselo, nto leyo ethintela ngokufanelekileyo ungcoliseko lwemveliso.

Ukumelana nokunxitywa kakuhle:

Nangona ukumelana nokuguguleka okungokwemvelo kwe-PTFE kungafanelekanga, i-CoF yayo ephantsi kakhulu inciphisa kakhulu amazinga okuguguleka. Xa idityaniswe ne-substrate yerabha efanelekileyo (enika inkxaso kunye nokuqina) kunye nokugqitywa/ukuthambisa okufanelekileyo komphezulu, ii-O-rings ezigqunyiweyo zihlala zibonisa ukumelana nokuguguleka okungcono kunee-O-rings zerabha ezingenanto kwizicelo eziguqukayo.

Ukumelana neekhemikhali okuphuculweyo kwe-substrate yerabha:

Olu gqubuthelo lukhusela ingaphakathi lerabha ekuhlaselweni yimidiya, luvumela ukusetyenziswa kwezinto zerabha ezineempawu ezingcono (ezifana nokuthamba okanye iindleko, umz., i-NBR) kwimidiya edla ngokudumba, iqine, okanye yonakalise irabha. "Iyayikhusela" ngokufanelekileyo ukuthamba kwerabha ngokumelana neekhemikhali ze-PTFE.

Ukuhambelana kakuhle kweVacuum:

Iingubo zePTFE ezikumgangatho ophezulu zinobunzima obuhle kwaye azinagesi kangako, zidibene nokuthamba kwesiseko serabha, nto leyo ebonelela ngokutywinwa kwe-vacuum okusebenzayo.

3. Izinto ezibalulekileyo ekufuneka ziqwalaselwe

Ixabiso: Iphezulu kunee-O-rings zerabha eziqhelekileyo.

Iimfuneko zoFakelo: Kufuneka kuphathwe ngononophelo ukuze kuthintelwe ukonakala kwengubo ngezixhobo ezibukhali. Iigroove zofakelo kufuneka zibe nee-chamfers ezifanelekileyo kunye nokugqitywa komphezulu ogudileyo.

Ukunyaniseka kokugquma: Umgangatho wokugquma (ukunamathela, ukufana, ukungabikho kwemingxuma) kubalulekile. Ukuba ukugquma kuphukile, irabha eveziweyo ilahlekelwa kukumelana kwayo neekhemikhali okwandisiweyo.

Iseti yoxinzelelo: Ngokuyintloko ixhomekeke kwisiseko serabha esikhethiweyo. Ingubo ngokwayo ayiniki amandla okumelana noxinzelelo.

Ubomi beNkonzo eguqukayo: Nangona ingcono kakhulu kunerabha engenanto, irabha ekugqibeleni iya kuguga xa ishukuma ixesha elide, itshintshatshintsha okanye ijikeleza. Ukukhetha irabha ezisisiseko ezingagugiyo (umz., i-FKM) kunye noyilo olulungisiweyo kunokwandisa ubomi.

Isishwankathelo

Ixabiso eliphambili lee-O-rings ezigqunywe yi-PTFE lilele kwindlela i-PTFE coating enika ngayo ukungangeni kakuhle kweekhemikhali, i-coefficient ephantsi kakhulu yokungqubana, uluhlu olubanzi lobushushu, iipropati ezinganamatheliyo, ucoceko oluphezulu, kunye nokhuseleko lwe-substrate kwii-O-rings zerabha zemveli. Zisisombululo esifanelekileyo kwimingeni yokutywina efunekayo ebandakanya ukugqwala okunamandla, ucoceko oluphezulu, ukungqubana okuphantsi, kunye nobubanzi bobushushu. Xa ukhetha, kubalulekile ukukhetha izinto ezifanelekileyo ze-substrate zerabha kunye neenkcukacha zokugquma ngokusekelwe kwisicelo esithile (imidiya, ubushushu, uxinzelelo, i-dynamic/static), kunye nokuqinisekisa ukufakwa kunye nokugcinwa ngokuchanekileyo ukuze kugcinwe ukuthembeka kwe-coating kunye nokusebenza kokutywina.

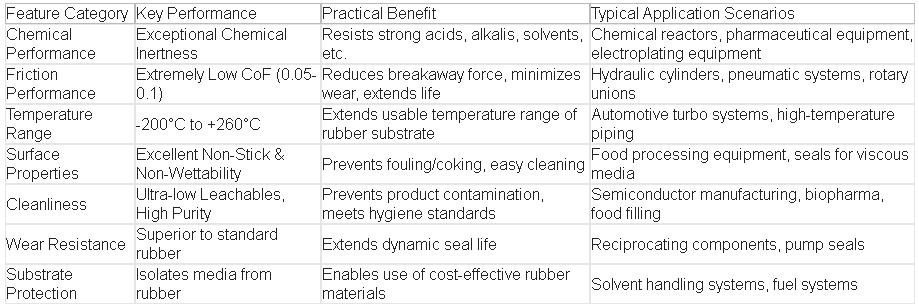

Itheyibhile engezantsi ishwankathela iimpawu eziphambili kunye nokusetyenziswa kwee-O-rings ezigqunywe yi-PTFE: