I-Polytetrafluoroethylene (PTFE), eyaziwa ngokuthi “inkosi yepulasitiki,” inikeza ukumelana kwamakhemikhali okumangalisayo, i-coefficient ephansi yokungqubuzana, kanye nokuqina emazingeni okushisa aphezulu. Kodwa-ke, ukulinganiselwa kwayo okungokwemvelo—njengokumelana nokuguguleka okubi, ubulukhuni obuphansi, kanye nokuthambekela ekukhukhulekeni—kuye kwaholela ekuthuthukisweni kwe-complementaryIzinhlanganisela ze-PTFENgokufaka ama-filler afana ne-glass fiber, i-carbon fiber, kanye ne-graphite, abakhiqizi bangakwazi ukwenza i-PTFE ibe yimpahla edingekayo ekufakweni kwe-aerospace, ezimotweni, kanye nasekuvalweni kwezimboni. Lesi sihloko sihlola ukuthi la ma-filler athuthukisa kanjani i-PTFE futhi anikeze isiqondiso sokukhetha inhlanganisela efanele ngokusekelwe ezidingweni zokusebenza.

1. Isidingo Sokuguqulwa kwe-PTFE

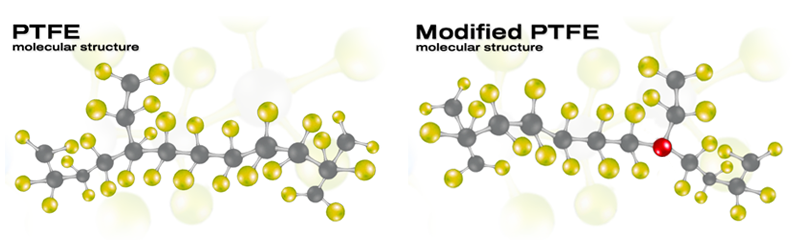

I-PTFE emsulwa idlula zonke ekumelaneni nokugqwala kanye nokungqubuzana okuphansi kodwa inobuthakathaka bemishini. Isibonelo, ukumelana kwayo nokugqwala akwanele ukusetshenziswa kokuvala okuguquguqukayo, futhi iyaguquguquka ngaphansi kwengcindezi eqhubekayo (ukugeleza okubandayo). Ama-Filler abhekana nalezi zinkinga ngokusebenza njengezinhlaka eziqinisayo ngaphakathi kwe-PTFE matrix, ethuthukisa ukumelana nokuqhekeka, ukubekezelela ukugqwala, kanye nokuqhuba ukushisa ngaphandle kokubeka engcupheni izinzuzo zayo eziyinhloko.

2. I-Glass Fiber: Isiqinisekisi Esingabizi Kakhulu

Izakhiwo Eziyinhloko

Ukumelana Nokugqokwa: I-Glass fiber (GF) yehlisa izinga lokugqokwa kwe-PTFE ngokuphindwe izikhathi ezifika ku-500, okwenza kube kuhle kakhulu ezindaweni ezithwala umthwalo omningi.

Ukunciphisa Ukucwila: I-GF ithuthukisa ukuzinza kobukhulu, inciphisa ukuguquguquka ngaphansi kokucindezeleka okuqhubekayo.

Imikhawulo Yokushisa Neyamakhemikhali: I-GF isebenza kahle emazingeni okushisa afinyelela ku-400°C kodwa yonakala ku-hydrofluoric acid noma ezisekelweni eziqinile.

Izicelo

I-PTFE eqiniswe yi-GF isetshenziswa kabanzi ezivalweni ze-hydraulic, amasilinda omoya, kanye nama-gasket ezimboni lapho amandla omshini kanye nokusebenza kahle kwezindleko kubhekwa khona kuqala. Ukuhambisana kwayo nezithasiselo ezifana ne-MoS₂ kuthuthukisa kakhulu ukulawulwa kokungqubuzana.

3. I-Carbon Fiber: Ukukhetha Okuphezulu Kokusebenza

Izakhiwo Eziyinhloko

Amandla Nokuqina: I-Carbon fiber (CF) inikeza amandla okuqina aphezulu kanye ne-flexural modulus, edinga amavolumu aphansi okugcwalisa kune-GF ukuze kufezwe ukuqina okufanayo.

Ukushisa Okushisayo: I-CF ithuthukisa ukushabalaliswa kokushisa, okubalulekile ekusetshenzisweni kwesivinini esikhulu.

Ukungasebenzi Kwamakhemikhali: I-CF imelana nama-asidi aqinile (ngaphandle kwama-oxidizer) futhi ifaneleka ezindaweni zamakhemikhali ezinzima.

Izicelo

Ama-composite e-CF-PTFE asebenza kahle kakhulu kuma-shock absorber ezimoto, imishini ye-semiconductor, kanye nezingxenye zezindiza, lapho ukuqina okulula kanye nokuphathwa kokushisa kubalulekile khona.

4. I-Graphite: Ingcweti Yokugcoba

Izakhiwo Eziyinhloko

Ukungqubuzana Okuphansi: I-PTFE egcwele i-Graphite ifinyelela ama-coefficient okungqubuzana aphansi njengo-0.02, okunciphisa ukulahleka kwamandla ezinhlelweni ezishintshashintshayo.

Ukuzinza Kokushisa: I-Graphite ithuthukisa ukuhanjiswa kokushisa, ivimbela ukwakheka kokushisa kokuxhumana okusheshayo.

Ukuhambisana Kokuthamba Okuthambile: Kunciphisa ukuguguleka ezindaweni ezithambile njenge-aluminium noma ithusi.

Izicelo

Izinhlanganisela ezisekelwe ku-graphite ziyathandwa kuma-bearings angagcotshwanga, kuma-compressor seal, nasemishinini ejikelezayo lapho ukusebenza kahle kanye nokushabalaliswa kokushisa kubalulekile khona.

5. Ukubuka Konke Okuqhathanisayo: Ukukhetha Isigcwalisi Esifanele

| Uhlobo Lokugcwalisa | Ukumelana Nokugqoka | I-Friction Coefficient | Ukushisa Okuphezulu | Okuhle Kakhulu |

| I-Glass Fiber | Okuphezulu (ukuthuthuka okuphindwe ka-500) | Okumaphakathi | Okumaphakathi | Izimpawu eziqinile/ezishintshashintshayo ezibizayo, ezinomthwalo omningi |

| I-Carbon Fiber | Phezulu Kakhulu | Okuphansi kuya kokuphakathi | Phezulu | Izindawo ezilula, ezishisa kakhulu, nezigqwala |

| I-Graphite | Okumaphakathi | Kuphansi Kakhulu (0.02) | Phezulu | Izinhlelo zokusebenza ezingagcotshwanga, ezisheshayo |

Izinhlanganisela ze-Synergistic

Ukuhlanganisa ama-filler—isib. i-fiber yengilazi ne-MoS₂ noma i-carbon fiber ne-graphite—kungenza ngcono izakhiwo eziningi. Isibonelo, ama-hybrid e-GF-MoS₂ anciphisa ukungqubuzana ngenkathi egcina ukumelana nokuguguleka.

6. Imiphumela Yemboni Nokuzinza

Izinhlanganisela ze-PTFE ezigcwalisiwe zandisa isikhathi sokuphila kwezingxenye, zinciphisa imvamisa yokugcinwa, futhi zithuthukisa ukusebenza kahle kwamandla. Isibonelo, izivalo ze-graphite-PTFE ezinhlelweni ze-LNG zimelana namazinga okushisa kusukela ku--180°C kuya ku-+250°C, zisebenza kahle kakhulu kunezinye izinto ezivamile. Lokhu kuthuthuka kuhambisana nemigomo yomnotho oyindilinga ngokunciphisa imfucuza ngomklamo ohlala isikhathi eside.

Isiphetho

Ukukhetha i-filler—i-glass fiber, i-carbon fiber, noma i-graphite—kunquma ukusebenza kwe-PTFE composites. Nakuba i-glass fiber inikeza izindleko ezilinganisiwe kanye nokuqina, i-carbon fiber ihamba phambili ezimweni ezimbi kakhulu, futhi i-graphite ibeka phambili ukuthambisa. Ukuqonda lo mehluko kwenza onjiniyela bakwazi ukwenza izixazululo zokuvala zibe qotho futhi zisebenze kahle.

Njengoba izimboni zithuthuka ziye ezindinganisweni zokusebenza eziphakeme, ukusebenzisana nochwepheshe besayensi yezinto ezibonakalayo kuqinisekisa intuthuko engcono kakhulu yomkhiqizo. I-Ningbo Yokey Precision Technology isebenzisa ubuchwepheshe obuthuthukisiwe bokuhlanganisa ukuze ilethe izivalo ezihlangabezana nezidingo eziqinile zezinhlelo zokusebenza zezimoto, amandla, kanye nezimboni.

Amagama angukhiye: Izinhlanganisela ze-PTFE, izixazululo zokuvala, ubunjiniyela bezinto ezibonakalayo, izinhlelo zokusebenza zezimboni

Izinkomba

Amasu Okuguqula Izinto ze-PTFE (2017).

Izinto ze-PTFE ezihlanganisiwe – i-Micflon (2023).

Imiphumela Yokugcwalisa Ezimpahleni ze-PTFE – I-Global Tribune (2021).

Ukusebenza kwe-PTFE Gasket okushintshiwe (2025).

Ukuthuthukiswa Okuthuthukisiwe kwe-Fluoropolymer (2023).

Isikhathi sokuthunyelwe: Jan-09-2026