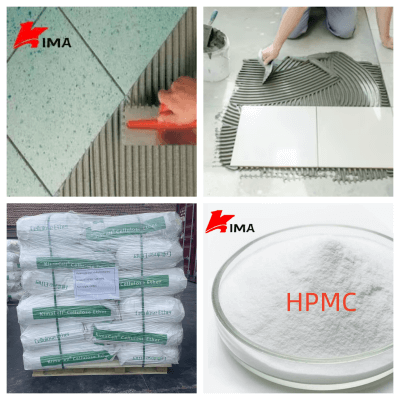

I-Hydroxypropyl Methylcellulose (HPMC)iyi-non-ionic cellulose ether esetshenziswa kabanzi ezintweni zokwakha, ikakhulukazi kuma-adhesive ethayela. I-HPMC isibe yinto ebalulekile ekuhlobiseni izakhiwo zesimanje ngokuthuthukisa ukusebenza kokwakha, ukugcinwa kwamanzi, kanye namandla okubopha ama-adhesive ethayela.

1. Thuthukisa ukusebenza kokwakha

1.1. Thuthukisa ukusebenza kahle

I-HPMC inokuthambisa nokunamathela okuhle. Ukuyifaka ku-adhesive yethayela kungathuthukisa kakhulu ukusebenza kahle kwe-mortar, kwenze kube lula ukuyiklwebha nokuyishelela, futhi kuthuthukise ukusebenza kahle kanye nekhwalithi yokwakha yezisebenzi zokwakha.

1.2. Vimbela ukugoba

Uma i-adhesive yethayela isetshenziswa endaweni eqondile, kulula ukugoba ngenxa yesisindo sayo. I-HPMC ithuthukisa ngempumelelo isici sokungagobi se-adhesive ngokusebenzisa izakhiwo zayo zokujiya kanye ne-thixotropic, ukuze amathayili akwazi ukugcina indawo eqinile ngemva kokugandaya nokuvimbela ukushelela.

2. Thuthukisa ukugcinwa kwamanzi

2.1. Nciphisa ukulahleka kwamanzi

I-HPMC inokusebenza okuhle kakhulu kokugcina amanzi. Inganciphisa kakhulu ukuhwamuka kwamanzi ngokushesha noma ukumuncwa ungqimba oluyisisekelo lwe-adhesive yethayela, yandise isikhathi sokuvula nesikhathi sokulungisa i-adhesive ngempumelelo, futhi inikeze abasebenzi bokwakha ukuguquguquka okukhulu kokusebenza.

2.2. Khuthaza ukusabela kokumanziswa kwesimende

Ukugcinwa kwamanzi okuhle kusiza usimende ukuthi umanzise ngokugcwele futhi wakhe imikhiqizo yokumanzisa eningi, ngaleyo ndlela kuthuthukiswe amandla okubopha kanye nokuqina kwe-adhesive yethayela.

3. Thuthukisa amandla okubopha kanye namandla

3.1. Thuthukisa isakhiwo se-bonding interface

I-HPMC yakha isakhiwo senethiwekhi ye-polymer esihle ku-glue, okuthuthukisa ukusebenza kwe-bonding phakathi kwe-tile glue nama-tile kanye nesendlalelo sesisekelo. Kungakhathaliseki ukuthi amathayili ancelisayo noma amathayili anomunca amanzi aphansi (njengamathayili ane-vitrified nama-tile acwebezelisiwe), i-HPMC inganikeza amandla e-bonding azinzile.

3.2. Thuthukisa ukumelana nokuqhekeka kanye nokuguquguquka

Isakhiwo se-polymer se-HPMC senza i-tile adhesive ibe nokuguquguquka okuthile, okungazivumelanisa nokuguquguquka okuncane noma ukwanda kokushisa kanye nokufinyela kwesendlalelo sesisekelo, futhi kunciphise izinkinga zekhwalithi njengokugoba kanye nokuqhekeka okubangelwa ukugxilisa ingqondo.

4. Thuthukisa ukuzivumelanisa nezimo kokwakhiwa

4.1. Zivumelanise nezimo ezahlukene zokwakha

Ngaphansi kwezimo zezulu ezimbi njengokushisa okuphezulu, ukoma noma umoya onamandla, izinti ezivamile zamathayela zivame ukoma ngokushesha kakhulu, okuholela ekuhlulekeni kokubopha. I-HPMC ingalibazisa ngempumelelo ukulahleka kwamanzi ngenxa yokugcina kwayo amanzi okuhle kanye nezakhiwo zokwakha ifilimu, okwenza izinti ezinamathelayo zamathayela zivumelane nokwakhiwa okuvamile ezindaweni ezahlukene.

4.2. Kusebenza ezinhlotsheni ezahlukene ze-substrate

Kungakhathaliseki ukuthi ungqimba lokulinganisa udaka lukasimende, i-concrete slab, indawo yamathayela amadala noma i-gypsum substrate, izinamathiselo zamathayela ezine-HPMC ezengeziwe zinganikeza ukusebenza okuthembekile kokubopha, zandise ububanzi bokusetshenziswa kwazo.

5. Ukuvikelwa nokuphepha kwemvelo

I-HPMC iyinto eluhlaza futhi enobungani nemvelo engenabo ubuthi, engenaphunga, engashi, futhi engeke ilimaze imvelo noma impilo yabantu. Ayikhiphi izinto eziyingozi ngesikhathi sokwakhiwa, okuhambisana nomqondo wokuthuthukiswa kwezakhiwo zesimanje eziluhlaza.

6. Ukusebenza kahle kwezomnotho kanye nesikhathi eside

Nakuba izindleko ze-HPMC ziphakeme kancane kunezengezo zendabuko, zithuthukisa kakhulu ukusebenza kwezinamathiseli zamathayili, zinciphisa izinga lokulungiswa kabusha kanye nokuchithwa kwezinto, futhi zinezinzuzo eziphezulu kakhulu kwezomnotho ngokuhamba kwesikhathi. Izinamathiseli zamathayili ezisezingeni eliphezulu zisho ukunakekelwa okuncane, impilo yesevisi ende kanye nemiphumela engcono yokwakha.

7. Ukusebenzisana nezinye izithasiselo

I-HPMC ingasetshenziswa kanye nezinye izithasiselo ezahlukahlukene, njengeIzimpushana zePolymer Eziphinde Zihlakazeke(RDP), i-starch ether, i-ejenti yokugcina amanzi, njll., ukuze kuthuthukiswe ukusebenza kwezinamathelisi zethayela. Isibonelo, uma isetshenziswa ne-RDP, ingathuthukisa ukuguquguquka kanye namandla okubopha ngasikhathi sinye; uma isetshenziswa ne-starch ether, ingathuthukisa kakhulu ukugcinwa kwamanzi kanye nokushelela kokwakhiwa.

I-HPMC idlala indima ebalulekile ekunamathiseleni amathayili ezicini eziningiIzinzuzo zayo eziyinhloko zifaka phakathi ukuthuthukisa ukusebenza kokwakhiwa, ukuthuthukisa ukugcinwa kwamanzi, ukuthuthukisa ukunamathela, ukuthuthukisa ikhono lokulwa nokugoba, kanye nokuzivumelanisa nezinhlobo ezahlukene zezindawo kanye nezindawo. Njengesengezo esiyinhloko sokwakhiwa kwethayela lesimanje, i-HPMC ayihlangabezani nje kuphela nezidingo ezahlukahlukene zokwakha kwamanje, kodwa futhi ikhuthaza intuthuko yezobuchwepheshe kanye nentuthuko eluhlaza embonini yokunamathela amathayela.

Isikhathi sokuthunyelwe: Juni-24-2025