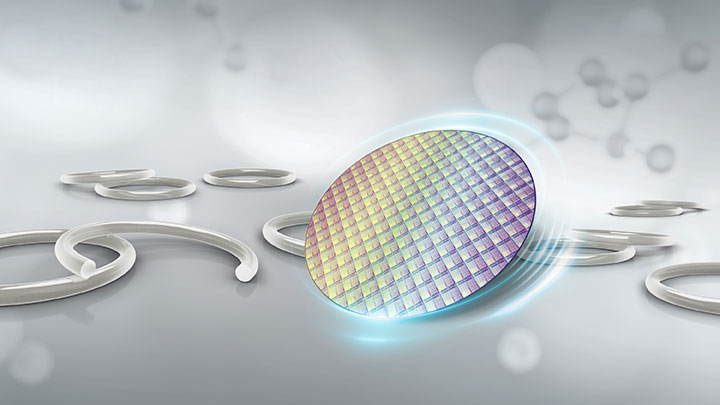

A fannin fasahar kere-kere ta zamani, kowane mataki yana buƙatar daidaito da tsafta na musamman. Hatimin roba na musamman, a matsayin muhimman abubuwan da ke tabbatar da ingantaccen aikin kayan aiki da kuma kiyaye muhallin samarwa mai tsafta, suna da tasiri kai tsaye kan yawan amfanin da ingancin kayayyakin semiconductor. A yau, za mu yi nazari kan yadda hatimin roba na musamman kamar fluororubber da perfluoroelastomer ke taka muhimmiyar rawa a masana'antar semiconductor.

I. Bukatu Masu Tsauri na Muhalli na Masana'antar Semiconductor

Ana yin kera semiconductor yawanci a cikin ɗakunan tsafta, inda buƙatun tsaftar muhalli ke da matuƙar yawa. Ko da ƙananan barbashi na gurɓatawa na iya haifar da gajerun da'irori ko wasu lahani na aiki. Bugu da ƙari, tsarin kera ya ƙunshi amfani da nau'ikan sinadarai masu lalata sosai, kamar su masu hana haske, maganin etching, da ruwan tsaftacewa. Bugu da ƙari, wasu matakan tsari suna fuskantar babban canjin zafin jiki da matsin lamba. Misali, etching da ion dasawa suna haifar da yanayin zafi mai yawa da matsin lamba a cikin kayan aiki. Bugu da ƙari, hatimin hatimi na iya yin babban tasiri ga masana'antar semiconductor. Ko da ƙananan adadin hatimin na iya gurɓata kayan semiconductor ko hanyoyin aiki, yana kawo cikas ga daidaiton tsarin samarwa.

II. Muhimman Ayyukan Hatimin Roba na Musamman

1. Hana Gurɓatar Barbashi: Rufin roba na musamman yana toshe ƙura, datti, da sauran barbashi daga muhallin waje daga shiga kayan aiki, yana kiyaye muhalli mai tsafta. Idan aka yi la'akari da hatimin perfluoroelastomer a matsayin misali, santsinsu yana hana shan barbashi. Kyakkyawan sassaucin da suke da shi yana ba su damar dacewa da kayan aikin, yana samar da shinge mai inganci da kuma tabbatar da cewa tsarin kera semiconductor ba shi da gurɓataccen barbashi.

2. Juriya ga Tsabtace Sinadarai: Hatimai kamar fluorocarbon da perfluoroelastomer suna ba da juriya mai kyau ga sinadaran da ake amfani da su a masana'antar semiconductor. Hatimin fluorocarbon yana da juriya ga ruwan acidic da alkaline da kuma ruwan halitta, yayin da hatimin perfluoroelastomer suna da ƙarfi musamman a cikin yanayin sinadarai masu guba da lalata. Misali, a cikin tsarin etching mai danshi, hatimin perfluoroelastomer na iya jure wa dogon lokaci tare da ruwan acidic mai guba ba tare da tsatsa ba, yana tabbatar da hatimin da kwanciyar hankali na kayan aiki.

3. Daidaita Canjin Zafi da Matsi: Kayan aikin kera semiconductor suna fuskantar canjin zafin jiki da matsin lamba akai-akai yayin aiki. Hatimin roba na musamman yana buƙatar juriya mai kyau na zafi da ƙarancin zafi, da kuma kyakkyawan sassauci da juriyar matsin lamba. Hatimin fluororubber yana kiyaye kyakkyawan sassauci da halayen rufewa a cikin wani takamaiman kewayon zafin jiki, yana daidaitawa da canjin zafin jiki a lokacin matakai daban-daban na sarrafawa. Hatimin Perfluoroelastomer, a gefe guda, ba wai kawai yana jure yanayin zafi mai yawa ba har ma yana tsayayya da yin tauri ko rauni a ƙananan yanayin zafi, yana kiyaye ingantaccen aikin rufewa da kuma tabbatar da aikin kayan aiki na yau da kullun a ƙarƙashin yanayi daban-daban na aiki mai rikitarwa.

4. Sarrafa Haɗarin Ruwan Sama: Sarrafa ruwan sama daga hatimi yana da matuƙar muhimmanci a masana'antar semiconductor. Hatimin roba na musamman kamar fluoroelastomer da perfluoroelastomer suna amfani da ingantattun tsari da hanyoyin samarwa don rage amfani da ƙarin abubuwa daban-daban, ta haka rage yuwuwar ruwan datti kamar ƙananan ƙwayoyin halitta da ions na ƙarfe yayin aikin ƙera su. Waɗannan halayen ruwan sama masu ƙarancin yawa suna tabbatar da cewa hatimin ba su zama tushen gurɓatawa ba, suna kiyaye yanayin tsafta da ake buƙata don ƙera semiconductor.

III. Bukatun Aiki da Sharuɗɗan Zaɓe don Hatimin Roba na Musamman

1. Halayen Tsafta: Tsaftacewar saman, canjin yanayi, da sakin barbashi sune manyan alamomin hatimi. Hatimin da ke da ƙarancin tsatsa a saman ba sa fuskantar taruwar barbashi, yayin da ƙarancin tsatsa ke rage haɗarin fitar da iskar gas daga hatimi a cikin yanayin zafi mai yawa. Lokacin zaɓar hatimi, fifita samfuran da ke da maganin musamman na saman da ke ba da ƙarancin canzawa da fitar da barbashi. Misali, hatimin perfluoroelastomer da aka yi wa magani da plasma yana ba da saman da ya yi laushi kuma yana rage canjin yanayi yadda ya kamata. Hakanan, kula da halayen sakin hatimin kuma zaɓi samfuran da aka yi gwajin fitarwa mai tsauri don tabbatar da cewa ba sa fitar da hayaki mai cutarwa a cikin yanayin masana'antar semiconductor.

2. Daidaita sinadarai: Zaɓi kayan roba da ya dace bisa ga takamaiman sinadaran da aka ci karo da su yayin ƙera semiconductor. Nau'o'in fluoroelastomer da perfluoroelastomer daban-daban suna da juriya daban-daban ga sinadarai daban-daban. Don hanyoyin da suka shafi ƙarfi na acid mai hana iskar oxygen, dole ne a zaɓi hatimin perfluoroelastomer mai yawan oxidizing. Don hanyoyin da suka shafi sinadarai na halitta gabaɗaya, hatimin fluoroelastomer na iya zama zaɓi mafi inganci.

3. Halayen jiki: Waɗannan sun haɗa da tauri, modulus mai laushi, da saitin matsi. Hatimai masu matsakaicin tauri suna tabbatar da kyakkyawan hatimi yayin da kuma suna sauƙaƙa shigarwa da cirewa. Modulus mai laushi da saitin matsi suna nuna daidaiton aikin hatimi a ƙarƙashin damuwa na dogon lokaci. A cikin yanayin zafi da matsin lamba mai yawa, ya kamata a zaɓi hatimai masu ƙarancin saitin matsi don tabbatar da aikin hatimi na dogon lokaci da kwanciyar hankali.

IV. Binciken Shari'o'in Amfani da Aiki

Wani sanannen masana'antar semiconductor yana fuskantar tsatsa da tsufa na hatimin roba na gargajiya a cikin kayan aikin ƙera guntu a layin kera guntu. Wannan ya haifar da ɓullar ciki, yana shafar ingancin samarwa da kuma rage yawan amfani da guntu saboda gurɓatar barbashi. Bugu da ƙari, hatimin gargajiya ya fitar da adadi mai yawa na ƙazanta na halitta a lokacin aikin zafi mai yawa, yana gurɓata kayan semiconductor kuma yana haifar da rashin daidaiton aikin samfur. Bayan maye gurbinsu da hatimin perfluoroelastomer da kamfaninmu ya ƙera, kwanciyar hankali na aikin kayan ya inganta sosai. Bayan shekara guda na ci gaba da sa ido kan aiki, hatimin bai nuna alamun tsatsa ko tsufa ba, yana kiyaye tsaftar ciki, da kuma ƙara yawan amfani da guntu daga 80% zuwa sama da 95%. An cimma wannan sakamakon godiya ga kyakkyawan juriyar sinadarai na hatimin perfluoroelastomer, ƙarancin halayen ruwan sama, da kyawawan halaye na zahiri, wanda ya haifar da fa'idodi masu yawa ga kamfanin.

Kammalawa: A masana'antar kera semiconductor, wacce ke ƙoƙarin tabbatar da daidaito da tsafta sosai, hatimin roba na musamman suna taka muhimmiyar rawa. Hatimin roba na musamman kamar fluoropolymer da perfluoroelastomer, tare da ingantaccen aikinsu, gami da cikakken iko kan ruwan sama, suna ba da ingantaccen hatimin ga kayan aikin kera semiconductor, suna taimaka wa masana'antar ci gaba da ci gaba zuwa manyan matakan fasaha.

Lokacin Saƙo: Oktoba-17-2025