Custom Food&Industrial Grade Rubber Hose

Detail

1. Hose structure is usually divided into three categories as follows:

1.1 Rubber hose with reinforced layer structure

1.1.1 Fabric reinforced rubber hose

1.1.2 Metal reinforced structural rubber hose

1.1.3 According to the structure of reinforcement layer

1.1.3.1 Laminated rubber hose: rubber hose made of coated fabric (or rubber cloth) as skeleton layer material, can be fixed with steel wire outside.

Features: clip cloth pressure hose is mainly made of plain woven cloth (its warp and weft density and strength are basically the same), cut by 45°, splicing, and wrapped. It has the advantages of simple manufacturing process, strong adaptability to product specifications and layer range, and good stiffness of pipe body. But it's inefficient.

1.1.3.2 Braided rubber hose: the rubber hose made of various wires (fiber or metal wire) as the skeleton layer is called braided rubber hose.

Features: The braided layers of the braided hose are usually interwoven according to the balance Angle (54°44 '), so the hose of this structure

It has good bearing performance, good bending performance and high material utilization ratio compared with the laminated rubber hose.

1.1.3.3 Winding rubber hose: The rubber hose made of various wires (fiber or metal wire) as the skeleton layer is called winding rubber hose. Features: similar to braided hose, high pressure strength, impact resistance and good flexure performance. High production efficiency.

1.1.3.4 Knitting hose: the hose made of cotton thread or other fibers as the skeleton layer is called knitting hose.

Features: knitting thread is interwoven on the inner tube billet at a certain Angle with the shaft. The intersection is sparse and generally consists of a single layer structure

Rubber hose commonly used in various automobile systems

|

Automotive systems |

Material |

Abbreviation |

comparison |

|

cooling water pipe |

Ethylene-Propylene-Diene Monomer Silicone |

EPDM VMQ(SIL) |

E: Temperature at ‐40‐‐ 150℃, not recyclable V: temperature ‐60‐ 200℃, not recyclable |

|

Fuel hose |

Nitrile-N rubber + chloroprene

Fluoro glue + chlorohydrin + chlorohydrin

Fluoro resin + chlorohydrin + chlorohydrin

Fluoro glue + fluoro resin + chlorol |

NBR+CR FKM+ECO THV+ECO FKM+THV+ECO |

NBR+CR: permeable emission below Euro ⅱ FKM+ECO: Seepage discharge below EURO ⅲ THV+ECO: Seepage discharge below Euro ⅳ FKM+THV+ECO: Infiltration discharge above Euro ⅳ |

|

Refueling hose |

Nitrile-N rubber + PVC

Nitrile-N rubber + chlorosulfonated polyethylene + chloroprene rubber

Fluoro glue + chlorohydrin

Fluoro glue + fluoro resin + chlorol |

NBR+PVC NBR+CSM+ECO FKM+ECO FKM+THV+ECO

|

NBR+PVC: eu ⅱ or below osmotic discharge, heat resistance NBR+CSM+ECO: penetration discharge below EURO ⅲ, good heat resistance FKM+ECO: Penetration discharge below Euro ⅳ, good heat resistance FKM+THV+ECO: Above Euro ⅳ infiltration discharge, good heat resistance |

|

Transmission oil cooling hose |

Acrylic rubber

Chlorosulfonated polyethylene

Epdm + neoprene |

ACM CSM EPDM+CR |

ACM: Japanese and Korean standard, oil direct cooling CSM: European and American standard, oil directly cooled EPDM+CR: German indirect water cooling |

|

Brake hose |

Ethylene-Propylene-Diene Monomer neoprene |

EPDM CR |

EPDM: brake fluid resistance, oil resistance, good low temperature CR: Brake fluid resistance, oil resistance, low temperature |

|

Air conditioning hose |

Ethylene-Propylene-Diene Monomer chlorinated butyl rubber |

EPDM CIIR |

Low permeability, high bonding strength with nylon layer |

|

The air filter is connected with the rubber hose |

Ethylene-Propylene-Diene Monomer Nitrile-N rubber + PVC epichlorohydrin rubber |

EPDM NBR+PVC ECO |

EPDM: temperature ‐40~150℃, oil resistant NBR+PVC: temperature ‐35~135℃, oil resistance ECO: temperature resistance in ‐40~175℃, good oil resistance |

|

Turbocharged hose |

Silicone rubber

Vinyl acrylate rubber

Fluororubber + silicone rubber |

VMQ AEM FKM+VMQ |

VMQ: temperature resistance in ‐60~200℃, slight oil resistance AEM: temperature resistance in ‐30~175℃, oil resistance FKM+VMQ: temperature resistance in ‐40~200℃, very good oil resistance |

|

Skylight drain |

Polyvinyl chloride (PVC)

Ethylene-Propylene-Diene Monomer rubber

Polypropylene +Ethylene-Propylene-Diene Monomer |

PVC EPDM PP+EPDM |

PVC: recyclable, hard at low temperature EPDM: non-recyclable, good low temperature resistance PP+EPDM: recyclable, good low temperature resistance, high cost |

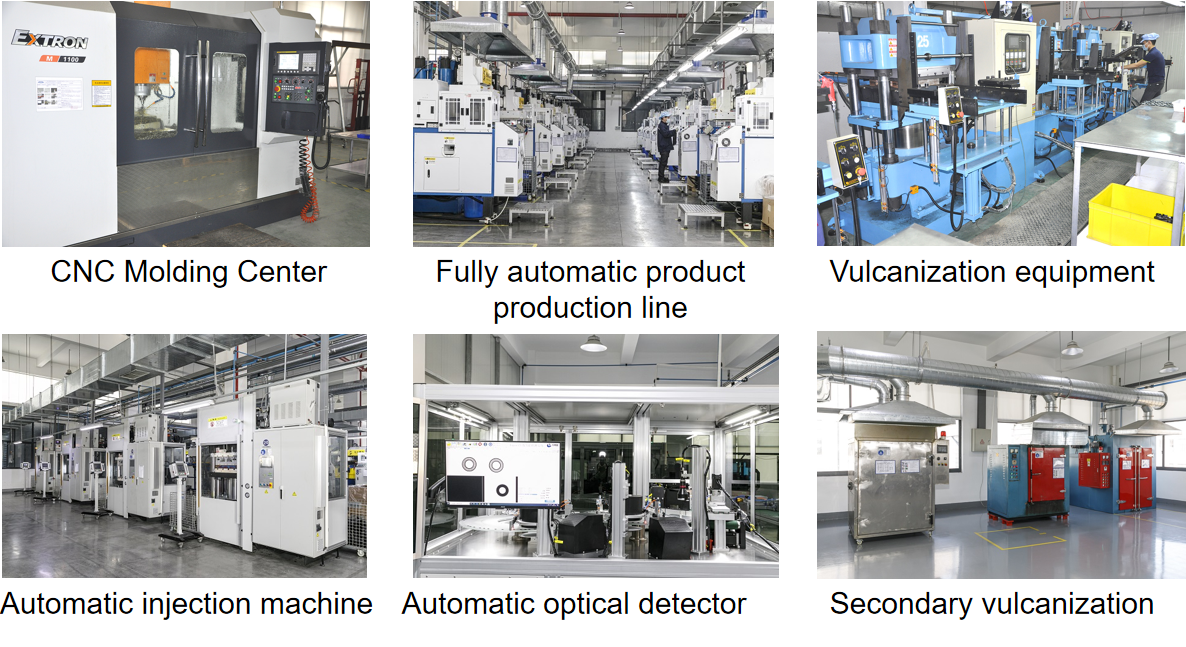

Workshop