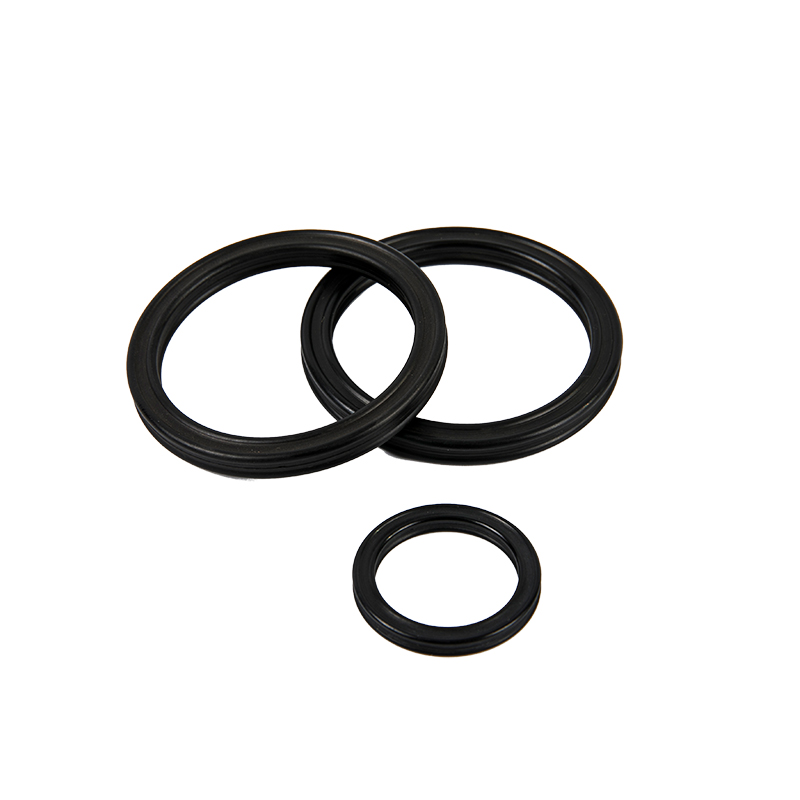

ODM High Quality O-Ring Nbr70 Manufacturer – High quality Sealing Rubber X-Ring – Yokey

ODM High Quality O-Ring Nbr70 Manufacturer – High quality Sealing Rubber X-Ring – Yokey Detail:

Different Material Rubber Parts

Silicone O-ring Gasket

1. Name: SIL/ Silicone/ VMQ

3. Working Temp.: -60 ℃ to 230 ℃

4. Advantage: Excellent resistance to Low temp. heat and elongation;

5. Disadvantage: Bad performance to tear, abrasion, gas, and Alkaline.

EPDM O-ring

1. Name: EPDM

3. Working Temp.:-55 ℃ to 150 ℃

4.Advantage:Excellent resistance to Ozon ,Flame, Weathering.

5.Disadvantage:Poor resistance to Oxygen Ated-solvent

FKM O-ring

FKM is a better grade compound which is well suited for prolonged exposure to oils at high operating temperatures.

FKM is also good for steam applications. Operating temperature range is -20℃ to 220℃ and is manufactured in black,white and brown. FKM is phthalate free and also available in metal detectable/x-ray inspectable.

Buna-N NBR Gasket O-ring

Abbreviation: NBR

Common Name:Buna N, Nitrile, NBR

Chemical Definition:Butadiene Acrylonitrile

General Characteristics:Waterproof,oilproof

Durometer-Range (Shore A):20-95

Tensile Range (P.S.I):200-3000

Elongation (Max.%):600

Compression Set:Good

Resilience-Rebound:Good

Abrasion Resistance:Excellent

Tear Resistance:Good

Solvent Resistance:Good to Excellent

Oil Resistance:Good to Excellent

Low Temperature Usage (°F):-30° to – 40°

High Temperature Usage (°F):to 250°

Aging Weather-Sunlight:Poor

Adhesion To Metals:Good to Excellent

Usal Hardness range:50-90 shore A

Advantage

1. Has good solvent, oil, water and hydraulic fluid resistance.

2. Good compression set, abrasion resistance and tensile strength.

Disadvantage

Not recommended for using in highly polar solvents such as acetone, and MEK, ozone, chlorinated hydrocarbons and nitro hydrocarbons.

Usage: fuel tank, grease-box, hydraulic, gasoline, water, silicone oil, etc.

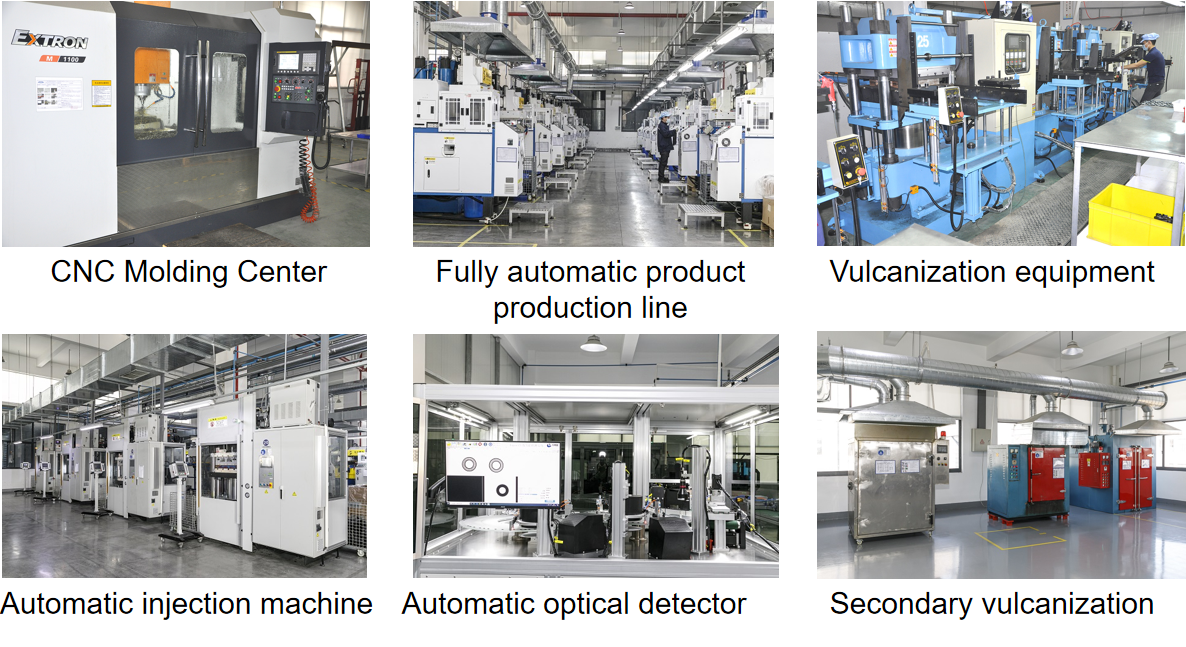

Workshop

Product detail pictures:

Related Product Guide:

We often stay with the principle Quality Very first, Prestige Supreme. We have been fully committed to supplying our consumers with competitively priced high-quality goods, prompt delivery and skilled provider for ODM High Quality O-Ring Nbr70 Manufacturer – High quality Sealing Rubber X-Ring – Yokey , The product will supply to all over the world, such as: St. Petersburg, Slovak Republic, Roman, Now, we professionally supplies customers with our main products And our business is not only the buy and sell, but also focus on more. We target to be your loyal supplier and long-term cooperator in China. Now, We hope to be the friends with you.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.