Valve Seals for Fire Fighting Equipment

Product Details

Metal VS coated parts, the name of this model is copper valve stem, Metal such as brass, aluminum, steel or stainless steel can be offered with bonding to all elastomer types. Customized size and material according to customer requirements, used in Fire equipment, fire extinguishers, etc. We supply the whole piece.

Product Advantages

Precisely manufactured

High endurance parts

Bonds on any type of metal

Fully meet your customization requirements

Our Advantage

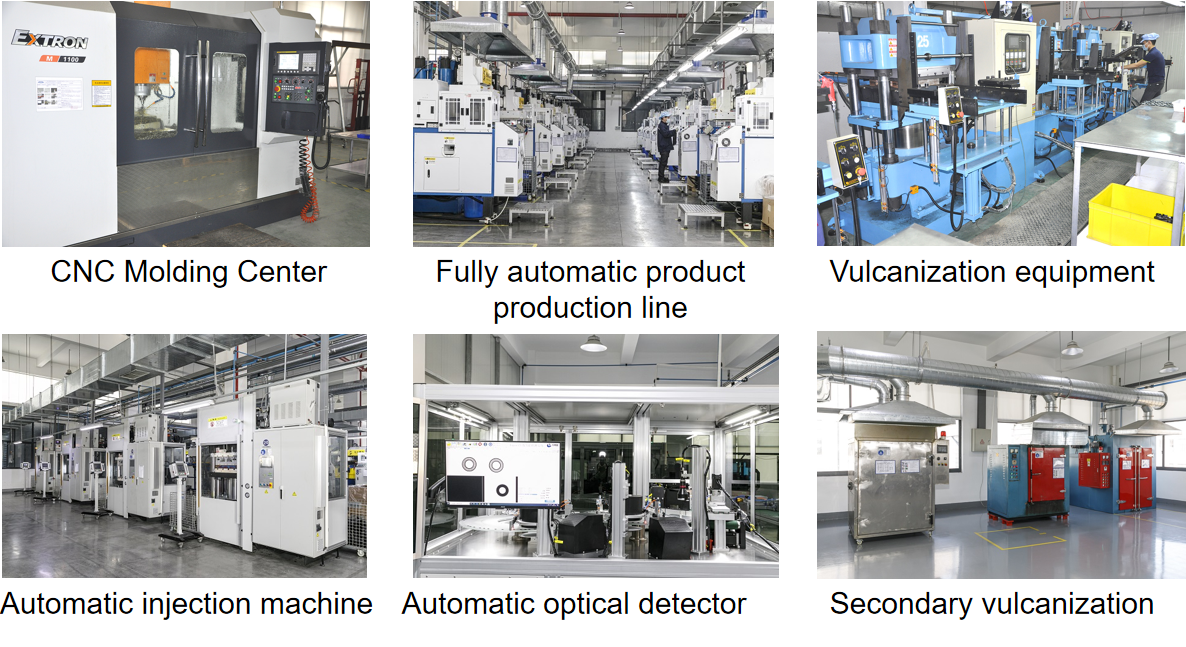

1. Advanced production equipment:

CNC machining center, rubber mixing machine, preforming machine, vacuum hydraulic molding machine, automatic injection machine, automatic edge removal machine, secondary vulcanizing machine (oil seal lip cutting machine, PTFE sintering furnace), etc.

2. Perfect inspection equipment:

①No rotor vulcanization tester (test at what time and at what temperature the vulcanization performance is the best).

②Tensile strength tester (press the rubber block into a dumbbell shape and test the strength on the upper and lower sides).

③The hardness tester is imported from Japan (the international tolerance is +5, and the company's shipping standard is +3).

④The projector is produced in Taiwan (used to precisely measure product size and appearance).

⑤Automatic image quality inspection machine (automatic inspection of product size and appearance).

3.Exquisite technology:

①Has a seal R&D and manufacturing team from Japanese and Taiwanese companies.

② Equipped with high-precision imported production and testing equipment:

A. Mould machining center imported from Germany and Taiwan.

B. Key production equipment imported from Germany and Taiwan.

C. The main testing equipment is imported from Japan and Taiwan.

③Using the international leading production and processing technology, the production technology originates from Japan and Germany.

4. Stable product quality:

① All raw materials are imported from: NBR nitrile rubber, Bayer, FKM, DuPont, EPDM, LANXESS, SIL silicone, Dow Corning.

②Before shipment, it must undergo more than 7 strict inspections and tests

③Strictly implement ISO9001 and IATF16949 international quality management system.

Workshop