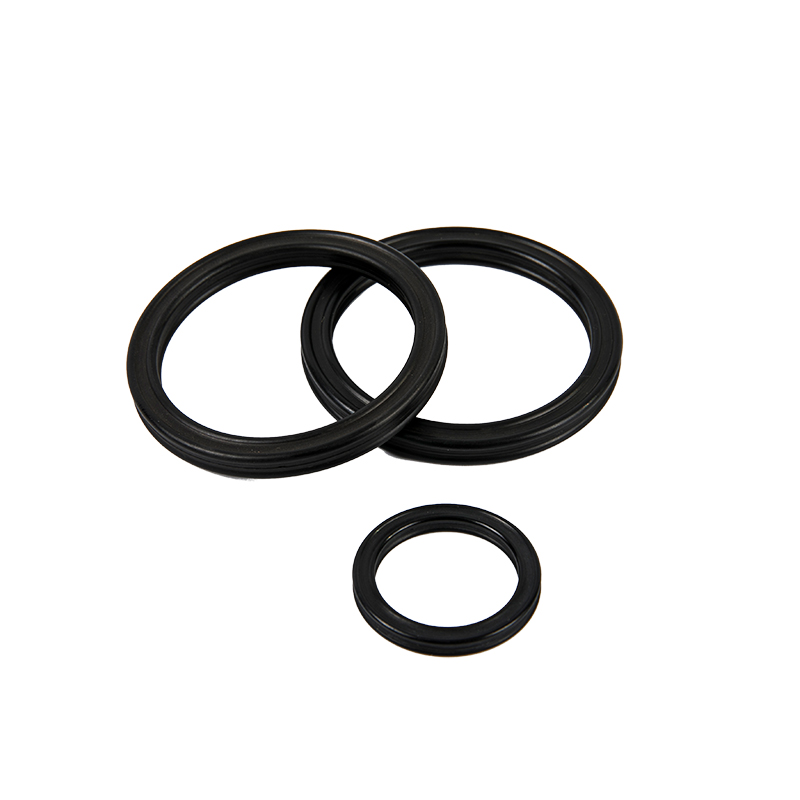

Renewable Design for High Temperature Resistance HNBR FKM Silicon Rubber X-Ring Seal Ring

Gaining purchaser gratification is our company’s aim eternally. We’re going to make great initiatives to create new and top-quality products, satisfy your exclusive prerequisites and supply you with pre-sale, on-sale and after-sale solutions for Renewable Design for High Temperature Resistance HNBR FKM Silicon Rubber X-Ring Seal Ring, We guaranteed quality, if customers were not satisfied with the products’ quality, you can return within 7days with their original states.

Gaining purchaser gratification is our company’s aim eternally. We’re going to make great initiatives to create new and top-quality products, satisfy your exclusive prerequisites and supply you with pre-sale, on-sale and after-sale solutions for China Star Ring and Quad Ring, We take measure at any expense to achieve essentially the most up-to-date equipment and approaches. The packing of nominated brand is our a further distinguishing feature. The products to assure years of trouble-free service has attracted a great deal customers. The solutions are obtainable in improved designs and richer assortment, they’re created scientifically of purely raw supplies. It readily available in a variety of designs and specs for your selection. The most recent kinds are a great deal better than the preceding one particular and they are quite popular with lots of prospects.

Different Material Rubber Parts

Silicone O-ring Gasket

1. Name: SIL/ Silicone/ VMQ

3. Working Temp.: -60 ℃ to 230 ℃

4. Advantage: Excellent resistance to Low temp. heat and elongation;

5. Disadvantage: Bad performance to tear, abrasion, gas, and Alkaline.

EPDM O-ring

1. Name: EPDM

3. Working Temp.:-55 ℃ to 150 ℃

4.Advantage:Excellent resistance to Ozon ,Flame, Weathering.

5.Disadvantage:Poor resistance to Oxygen Ated-solvent

FKM O-ring

FKM is a better grade compound which is well suited for prolonged exposure to oils at high operating temperatures.

FKM is also good for steam applications. Operating temperature range is -20℃ to 220℃ and is manufactured in black,white and brown. FKM is phthalate free and also available in metal detectable/x-ray inspectable.

Buna-N NBR Gasket O-ring

Abbreviation: NBR

Common Name:Buna N, Nitrile, NBR

Chemical Definition:Butadiene Acrylonitrile

General Characteristics:Waterproof,oilproof

Durometer-Range (Shore A):20-95

Tensile Range (P.S.I):200-3000

Elongation (Max.%):600

Compression Set:Good

Resilience-Rebound:Good

Abrasion Resistance:Excellent

Tear Resistance:Good

Solvent Resistance:Good to Excellent

Oil Resistance:Good to Excellent

Low Temperature Usage (°F):-30° to – 40°

High Temperature Usage (°F):to 250°

Aging Weather-Sunlight:Poor

Adhesion To Metals:Good to Excellent

Usal Hardness range:50-90 shore A

Advantage

1. Has good solvent, oil, water and hydraulic fluid resistance.

2. Good compression set, abrasion resistance and tensile strength.

Disadvantage

Not recommended for using in highly polar solvents such as acetone, and MEK, ozone, chlorinated hydrocarbons and nitro hydrocarbons.

Usage: fuel tank, grease-box, hydraulic, gasoline, water, silicone oil, etc.

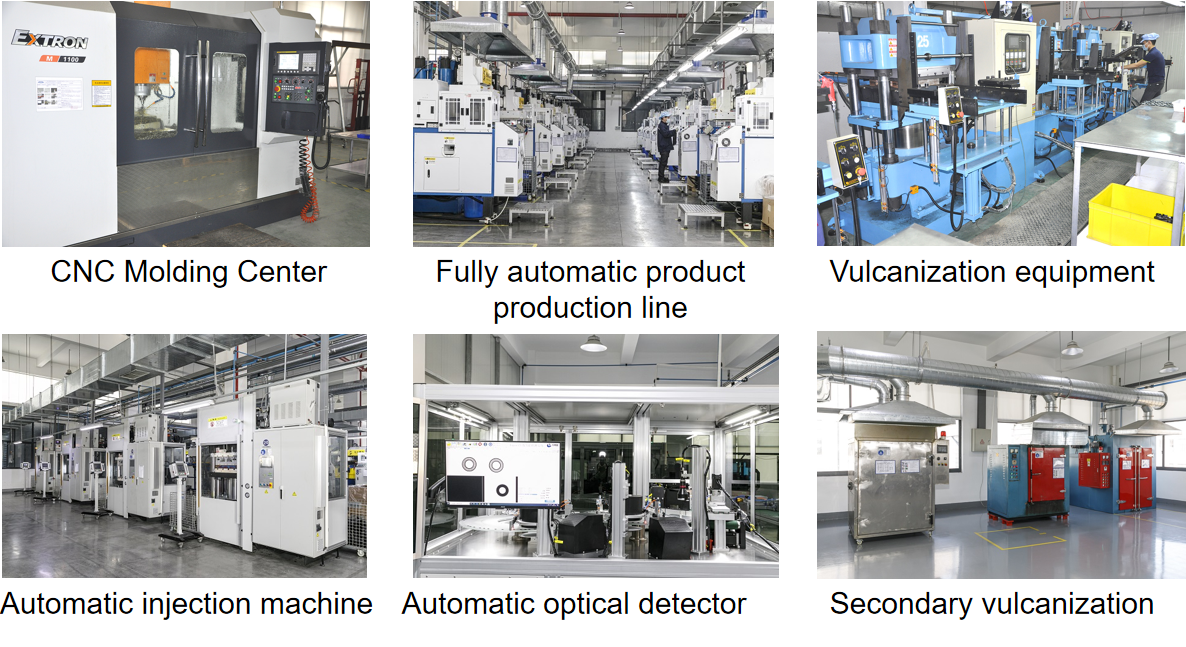

Workshop

Gaining purchaser gratification is our company’s aim eternally. We’re going to make great initiatives to create new and top-quality products, satisfy your exclusive prerequisites and supply you with pre-sale, on-sale and after-sale solutions for Renewable Design for High Temperature Resistance HNBR FKM Silicon Rubber X-Ring Seal Ring, We guaranteed quality, if customers were not satisfied with the products’ quality, you can return within 7days with their original states.

Gaining purchaser gratification is our company’s aim eternally. We’re going to make great initiatives to create new and top-quality products, satisfy your exclusive prerequisites and supply you with pre-sale, on-sale and after-sale solutions for Renewable Design for High Temperature Resistance HNBR FKM Silicon Rubber X-Ring Seal Ring, We guaranteed quality, if customers were not satisfied with the products’ quality, you can return within 7days with their original states.

Renewable Design for China Star Ring and Quad Ring, We take measure at any expense to achieve essentially the most up-to-date equipment and approaches. The packing of nominated brand is our a further distinguishing feature. The products to assure years of trouble-free service has attracted a great deal customers. The solutions are obtainable in improved designs and richer assortment, they’re created scientifically of purely raw supplies. It readily available in a variety of designs and specs for your selection. The most recent kinds are a great deal better than the preceding one particular and they are quite popular with lots of prospects.