ODM High Quality Back Up Ring Factories – High temperature resistance 320 ℃ FFKM O-Ring – Yokey

ODM High Quality Back Up Ring Factories – High temperature resistance 320 ℃ FFKM O-Ring – Yokey Detail:

Quick Details

|

Size: |

Customized, Customized |

Place of Origin: |

Zhejiang, China |

|

Brand Name: |

YOKEY/OEM |

Model Number: |

Customized |

|

Product name: |

FFKM O-Ring |

Hardness: |

50~88 Shore A |

|

Color: |

Customized |

Certification: |

RoHS/REACH/PAHS/KTW/NSF |

|

Application: |

Aging Resistance/Heat Resistance/Chemical Resistance |

Usage: |

All Industries |

|

MOQ: |

200 pcs |

Package: |

PE plastic bags + Cartons / Customized |

|

Samples: |

Free |

|

Specification

|

Material Type: FFKM |

Place of Origin: Ningbo, China |

|

Size: Customized |

Hardness Range: 50-88 Shore A |

|

Application: All Industries |

Temperature: -10°C to 320°C |

|

Color: Customized |

OEM / ODM: Available |

|

Feature: Aging Resistance/Acid and Alkali Resistance/Heat Resistance/Chemical Resistance/Weather Resistance |

|

|

Lead Time: 1).1days if goods in stock 2).10days if we have existing mould 3).15days if need open new mould 4).10days if annual requirement informed |

|

Detail

The main advantage of FFKM(Kalrez) is that it has both the elasticity and sealing properties of an elastomer and the chemical resistance and thermal stability of ptfe. FFKM(Kalrez) produces small amounts of gas in vacuum and exhibits high resistance to a variety of chemicals such as ethers, ketones, amines, oxidants, and many other chemicals. FFKM(Kalrez) retains rubber properties even when exposed to corrosive fluids at high temperatures. Therefore, FFKM(Kalrez) is widely used in semiconductor manufacturing, chemical transportation, nuclear industry, aircraft and energy and other industrial fields.

Chinese perfluoroether products, temperature resistance +230℃, preferential price

* Note: Kalrez is the brand name of perfluorinated elastomers owned by DuPont.

Kalrez part perfluorinated rubber properties overview:

Kalrez4079 Perfluoroether rubber seal ring

Properties: excellent chemical resistance, excellent compression and deformation properties when used at high temperature. But special attention is paid to the use of amine compounds. The temperature should be below 280 degrees when used under thermal cycling.

Heat resistance standard: 316℃

Hardness (Shore A) : 75

Kalrez7075 perfluoroether rubber seal ring

Performance: Compared with 4079, the compression permanent deformation rate is smaller, the sealing ability is better and the high temperature resistance is better, can work in 327 degrees high temperature environment.

Heat resistance standard: 327℃

Hardness (Shore A) : 75

Kalrez7075 Perfluoroether rubber seal Kalrez 6380

Kalrez6380 perfluoroether rubber sealing ring

Properties: milky white product, excellent broad – spectrum chemical resistance.

Heat resistance standard: 225 degrees

Hardness (Shore A) : 80

Performance: Compared with 4079, the compression permanent deformation rate is smaller, the sealing ability is better and the high temperature resistance is better, can work in 327 degrees high temperature environment.

Heat resistance standard: 327℃

Hardness (Shore A) : 75

Kalrez 7090

Kalrez7090 perfluoroether rubber sealing ring

Performance: high hardness, small compression permanent deformation rate, high heat resistant material.

Heat resistance standard: 325℃

Hardness (Shore A) : 90

Kalrez 1050LF

Kalrez1050LF perfluoroether rubber sealing ring

Properties: Suitable for the material of amine compounds. General chemical resistance is also excellent heat resistance.

Heat resistance standard: 288℃

Hardness (Shore A) : 82

Kalrez 6375

Kalrez6375 perfluoroether rubber sealing ring

Performance: have a broad spectrum of chemical resistance, suitable for the coexistence of multiple chemical media environment, heat resistant water and steam.

Hardness (Shore A) : 75

Heat resistance standard: 275℃

Kalrez 7375

Kalrez7375 perfluoroether rubber sealing ring

Performance: have a broad spectrum of chemical resistance, suitable for the coexistence of multiple chemical media environment, heat resistant water and steam.

Hardness (Shore A) : 75

Heat resistance standard: 275℃

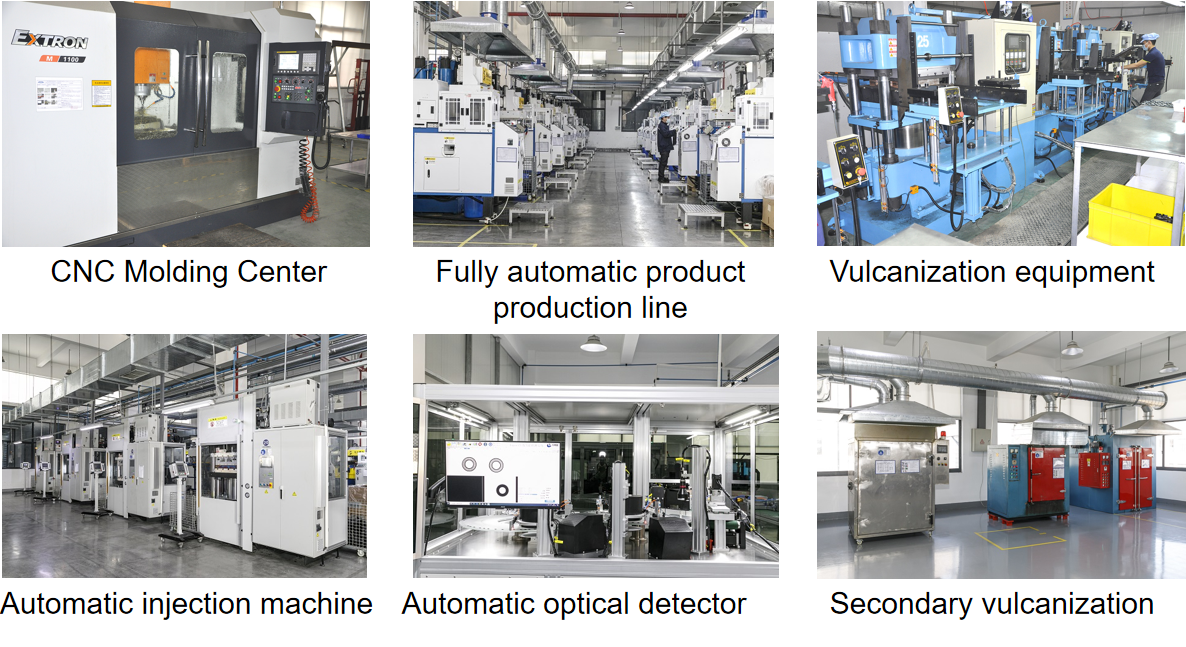

Workshop

Product detail pictures:

Related Product Guide:

With this motto in mind, we've got develop into amongst one of the most technologically innovative, cost-efficient, and price-competitive manufacturers for ODM High Quality Back Up Ring Factories – High temperature resistance 320 ℃ FFKM O-Ring – Yokey , The product will supply to all over the world, such as: Mali, Somalia, Malta, Customer's satisfaction is always our quest, creating value for customers is always our duty, a long term mutual-beneficial business relationship is what we are doing for. We are an absolutely reliable partner for yourself in China. Of course, other services, like consulting, can be offered too.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.