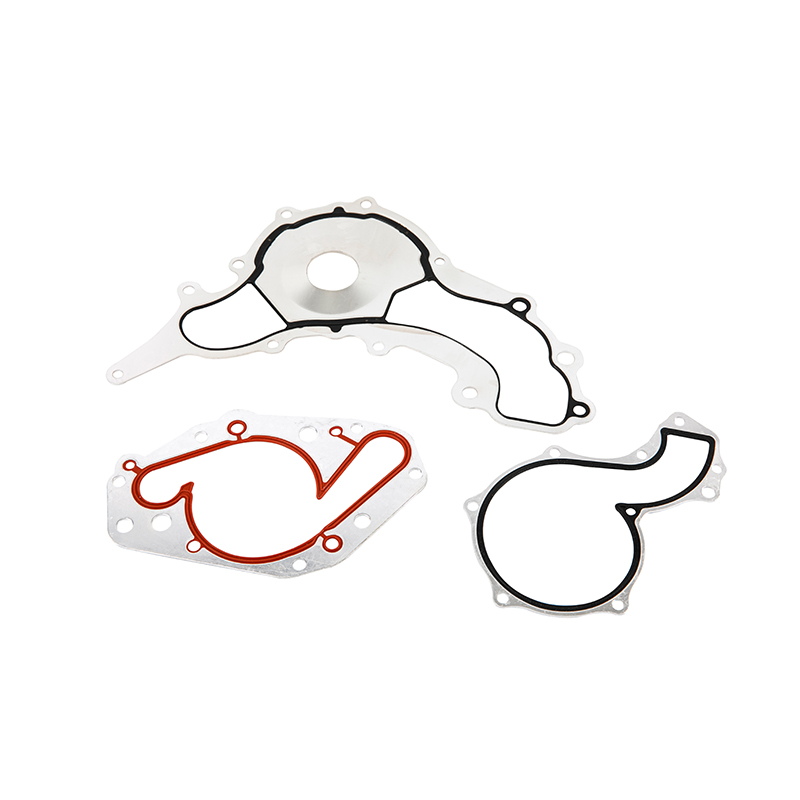

Butterfly Valve Gasket

Overview of Butterfly Valve Gaskets

Butterfly Valve Gaskets are indispensable components in the proper functioning of butterfly valves, which are pivotal in directing and regulating the flow of fluids within pipeline systems. These gaskets are meticulously engineered to ensure a secure seal, thereby preventing leaks and maintaining system pressure. Their role is paramount in various valve operations, particularly within the pipeline industry where reliability and safety are non-negotiable.

The Role of Butterfly Valve Gaskets in Pipelines

Within the pipeline industry, butterfly valves are often the preferred choice for their simplicity, low cost, and ease of operation. The gasket plays a critical role in this setup:

Pressure Maintenance: By ensuring a tight seal, gaskets help maintain the desired pressure within the pipeline, which is crucial for efficient fluid transport.

Flow Control: They assist in precisely controlling the flow rate by allowing the valve to close fully, preventing any bypass of fluid around the valve disc.

System Protection: Gaskets prevent leaks that could lead to environmental hazards, equipment damage, or loss of product, thus safeguarding both the system and the surrounding environment.

Key Features of Butterfly Valve Gaskets

Superior Sealing Capabilities

Butterfly Valve Gaskets are designed to provide a superior seal under varying pressure conditions, ensuring the valve's reliability in containing fluids.

Material Strength and Durability

Made from high-grade materials, these gaskets offer excellent resistance to wear and tear, extending the lifespan of both the gasket and the valve.

Compatibility with Various Fluids

They are compatible with a broad spectrum of fluids, including water, oil, and certain chemicals, making them versatile for different pipeline applications.

Resistance to Temperature Extremes

Capable of withstanding a wide range of temperatures without degradation, ensuring consistent performance across diverse operating conditions.

Technical Specifications and Selection Criteria

When selecting Butterfly Valve Gaskets for pipeline applications, consider the following technical specifications:

Material Composition: Choose gaskets made from materials that offer the best balance of chemical resistance, temperature tolerance, and mechanical strength for your specific application.

Size and Shape: Ensure the gasket's dimensions match the valve's design to guarantee a proper fit and effective seal.

Pressure Rating: Select a gasket with a pressure rating that meets or exceeds the maximum pressure expected in your pipeline system.

Compliance with Standards: Opt for gaskets that comply with industry standards to ensure reliability and safety.

Maintenance and Replacement

Proper maintenance and timely replacement of Butterfly Valve Gaskets are crucial for continued system efficiency:

Regular Inspections: Periodically inspect gaskets for signs of wear, degradation, or damage.

Replacement Indicators: Replace gaskets when they show signs of failure, such as increased leakage or difficulty in operation.

Storage Conditions: Store gaskets in a clean, dry environment away from extreme temperatures to maintain their integrity.