Heat Resistant FKM FFKM Rubber O-Ring Brown/Black Rubber Seal O-Rings

Detail

0-Rings are used in sanitary pipeline systems for the Auto, Machinery, Food, Dairy, Beverage, Pharmaceutical and Bio-Tech industries. Rubber Fab offers a full line of AS568 dash numbers, metric, and specialty o-ring sizes that are manufactured using EPDM, NBR, FKM Fluoroelastomer, Buna-N, PTFE, Silicone and so on.

The o-rings used in cylinder, pump, railcars, truck, washing machine, instrument and meter, mine equipment, pipeline, household appliances, automobile, steamboat, industrial electrical equipment, building door& window, construction machinery, construction bridges and tunnel.

1. mechanical sealing, pressure vessel ,gas compressor, reaction vessel ,heat exchanger, boiler, filter and so on.

2. It can be used for all kinds of electronic products in a wide range ,such as camera, mobile phone, printer, computer.

3. Used for automobile windows and doors, etc...

4. Silk screen printing, spray coating, laser etching, backlighted, hard/epoxy coating keypads.

Specification

|

Material Type: FKM/FFKM |

Place of Origin: Ningbo, China |

|

Size: Customized |

Hardness Range: 40-90 Shore A |

|

Application: All Industries |

Temperature: -20°C to 200°C |

|

Color: Customized |

OEM / ODM: Available |

|

Feature: Ozone Resistant/Acid and Alkali Resistance/Heat Resistance/Chemical Resistance/Weather Resistance |

|

|

Lead Time: 1).1days if goods in stock 2).10days if we have existing mould 3).15days if need open new mould 4).10days if annual requirement informed |

|

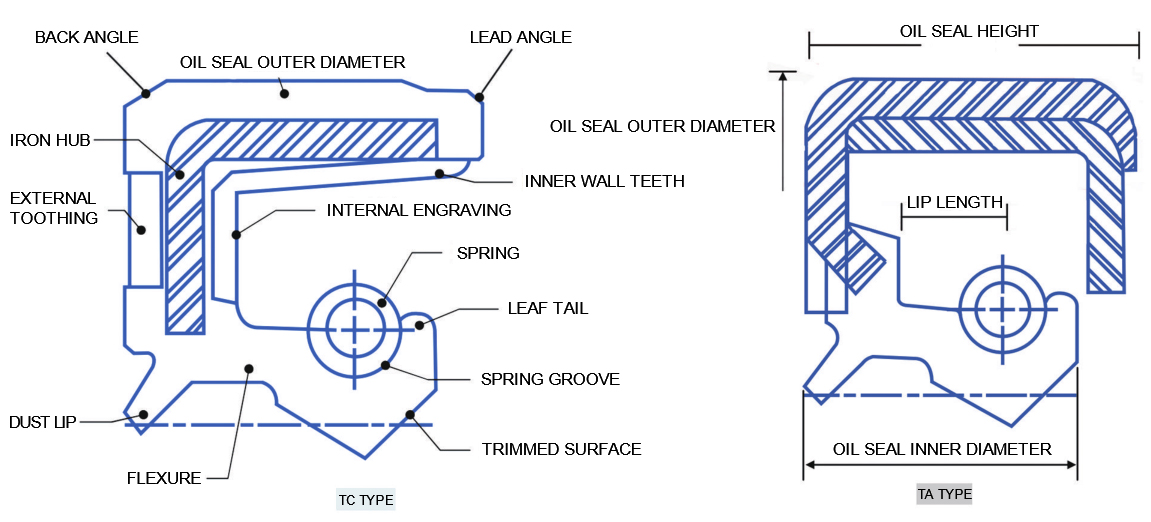

what is oil seal?

Oil seals prevent liquids such as lubricants, water and gases used in mechanical products from leaking out of "crevices". They also prevent dust, dirt and sand particles from entering from the outside.

Oil seal is an essential tool for sealing machinery in automobiles, airplanes, ships, railway carriages, construction machinery, agricultural machinery, petrochemical factories, household appliances and other fields.

what are the common forms of oil seal?

TC oil seal is the most commonly used form of oil seal at present. TC oil seal is an external rubber inner skeleton oil seal with self-tightening spring.

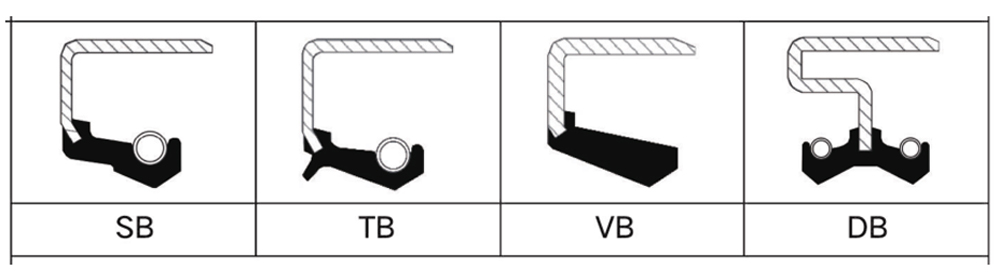

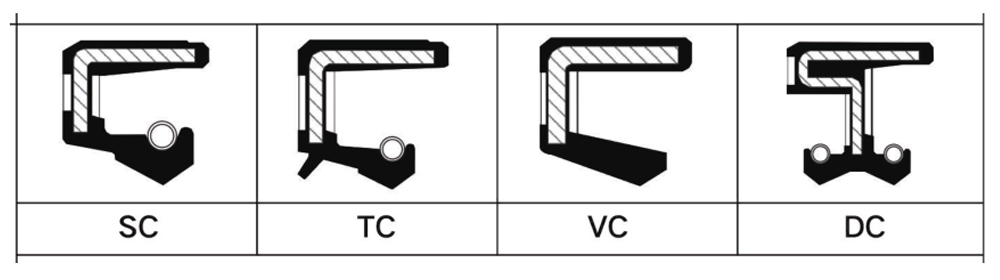

Common different types of internal and external skeleton oil seal structure:

La-type inner skeleton oil seal: including skeleton, fastening spring and rubber body

1, main features: double layer outer iron shell design, strengthen the outer iron shell design to strengthen the rigidity of the oil seal, especially suitable for large size oil seal

2, common types: SA (single lip), TA (double lips), VA (single lip without double springs), KA (double lips without double springs), DA (double lips double springs)

L C type outer skeleton oil seal: including skeleton, fastening spring, rubber body and auxiliary lip

1. Main features: outer rubber design, inner skeleton, ensure the sealing performance of outer diameter, widely used in various materials of assembly holes, allowing large surface roughness

2, common types: SC (single lip), TC (double lips), VC (single lip without double springs), KC (double lips without double springs), DC (double lips double springs)

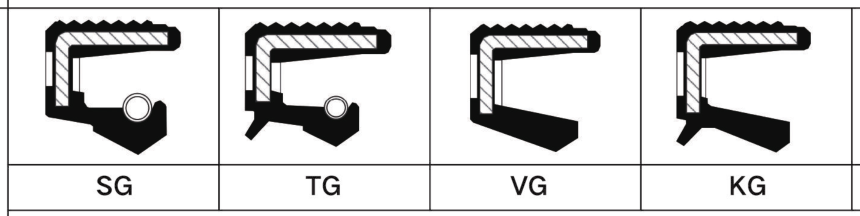

L G type oil seal: including frame, fastening spring, rubber body and auxiliary lip

1. Main features: Similar to type C design, outer diameter with thread, suitable for high thermal expansion material, assembly hole in high temperature environment room

2, common types :SG (single lip), TG (double lips), VG (single lip without double springs), KG (double lips without double springs)

Common E, F, H and so on.

what kind of oil seal?

According to the oil seal sealing speed, pressure resistance, temperature resistance, structural form, working state and sealing principle can be divided into a variety of different sealing forms.

1. According to the rotation speed of the axis, it can be divided into low speed oil seal (less than 6m/s) and high speed oil seal (greater than 6m/s).

2, according to the size of pressure capacity classification, can be divided into standard type oil seal and pressure type oil seal (more than 0.03mpa)

3, according to the oil seal structure and sealing principle classification, can be divided into standard oil seal and power return type oil seal

4, according to the composition of oil seal component material classification, can be divided into skeleton oil seal and skeleton oil seal; Spring oil seal and no spring oil seal

what are the common oil sealing materials?

|

Rubber |

Advantage |

Disadvantage |

|

NBR |

High cost performance, high use generally |

Poor stability at low temperature |

|

FKM |

1, chemical resistance 2, high temperature resistance 3, aging resistance |

1, high price 2, low temper0ature performance is poor |

|

HNBR |

1, heat resistance, oil resistance, ozone resistance 2, aging resistance, wear resistance 3, low temperature resistance is better than NBR |

higher price |

|

SIL |

Good heat resistance |

Poor mechanical strength, high price |

|

EPDM |

1, acid and alkali resistance 2, good electrical insulation 3, weather resistance, ozone resistance |

Not resistant to oil and fire |

|

PTFE |

1, acid/alkali/high pressure 2, wear resistance 3, high smoothness 4, continuous use of temperature up to 260℃ |

1, cold flow 2, not easy welding 3, not easy fusion processing |

What are the causes of oil seal leakage?

1, the oil seal lip mouth is not good, the spring quality is not good or failure, resulting in the spring holding force is too small

2, the oil seal installation tool is improper, the shaft end of the chamfering is improper, the smooth is too low, or the installation of too much force, resulting in damage to the lip of the oil seal or spring fall off

3, box body, end cover, shaft different centers, resulting in eccentric operation of the oil seal

4, improper pressure into the oil seal, so that tilt

5, oil seal and sealing liquid medium is incompatible, so that the sealing lip softening, swelling or cracking phenomenon.

6, improper repeated use, insufficient understanding of the service life of the oil seal, not regularly replaced, resulting in aging damage to the oil seal, is the sealing ability

What should be paid attention to when installing oil seals?

1, when assembling oil seal, attention should be paid to the spring holding force of oil seal

2, assembly parts are not allowed to have scars, burrs and so on

3. Before assembling the oil seal, the shaft and cavity should be cleaned carefully and coated with a layer of grease so as to wear the lip when installing the oil seal

4. Check whether the seal lip of the oil seal is damaged and deformed? At the same time, check whether the spring of the oil seal has fallen off?

5, the correct use of installation tools, protect the oil seal lip from damage

6. When the oil seal enters the cavity, it should be carried out with uniform pressure. Attention should be paid to not leaning into the internal control, otherwise it will cause the deformation of the oil seal and lead to leakage

7, when assembling, pay attention to the installation direction. When the inner seal is required, the side of the self-tightening spring is facing inside and the dustproof lip is outward

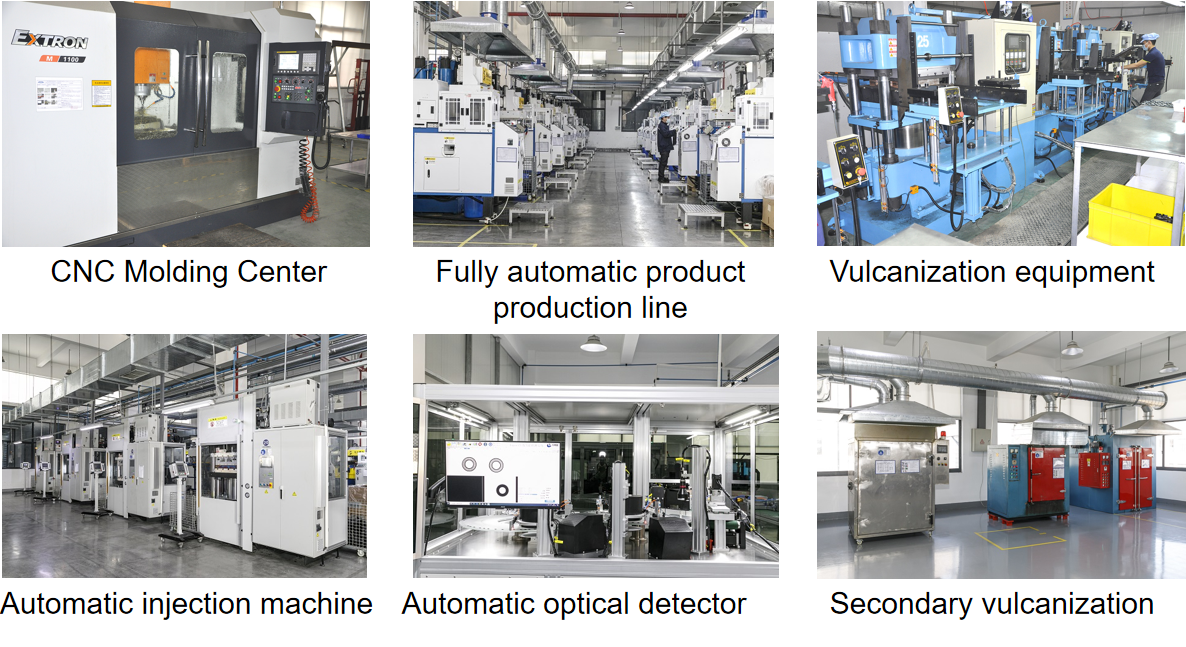

Workshop

Product Display

Temperature Range:-30Cto 125C

Hardness:40-90 Shore A

Color:Black,other color can customize

Use:Oil resistance situation

Advantage:Excellent oil resistance

performance and stability,widly used,

FKM(Fluorocarbon)

Temperature Range:-20Cto 250C

Hardness:50-90 Shore A

Color:Black/Brown/Green

other color can customize

Use:Oil resistance & Chemical situation

Advantage:Wear resistance,Acid and alkali

resistant,High temperature ersistance situation

Silicone Rubber(Q,MQ,VMQ,PVMQ)

Temperature Range:-60C to 225C

Hardness:25-90 Shore A

Color:Red/Transparent(Clear)/White,etc.

Use:Food situation(FDA Approved)

Advantage:Good heat resistance,Cold

resistance,Lubrication oil resistance,Water

resistance.